High-fatigue-life rubber belt and preparation method thereof

A fatigue life, rubber belt technology, applied in the field of high fatigue life rubber belt materials, can solve the problems of reduced life, running belt delamination or fracture, etc., to improve fatigue resistance, increase flex fatigue life, and improve friction performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

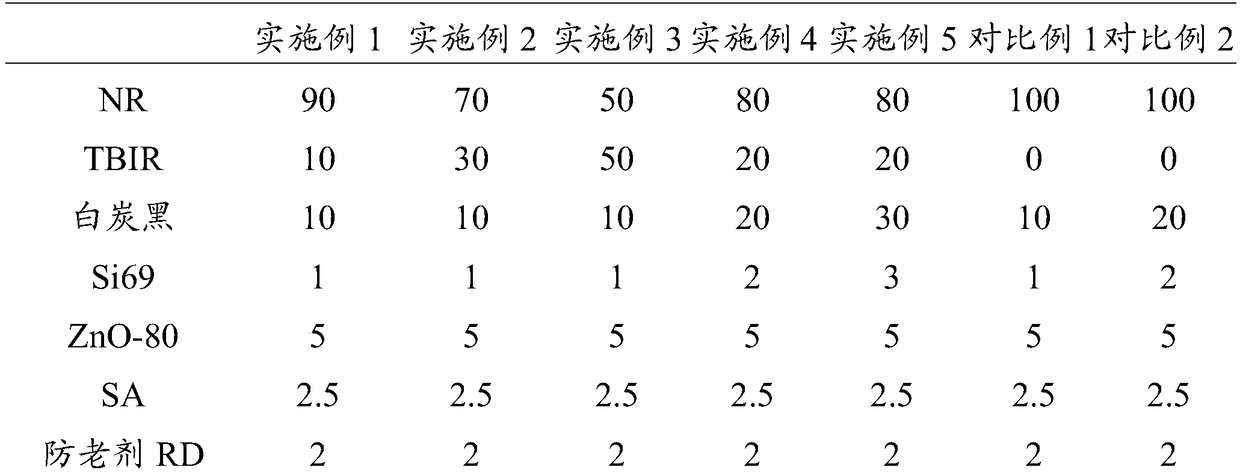

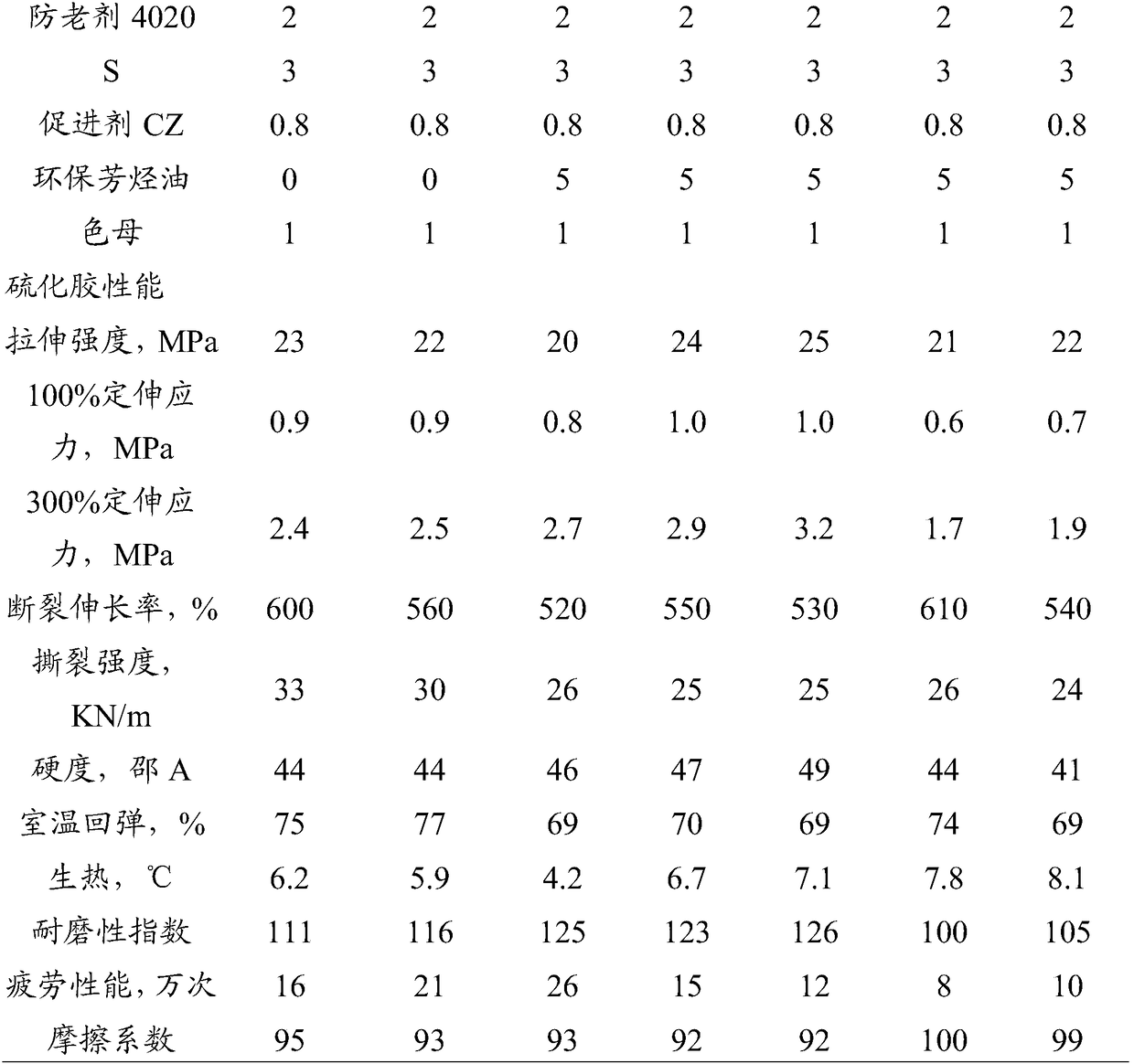

[0032] A kind of high fatigue life rubber belt, its formula composition is shown in Table 1. In the compound, high trans-1,4-butadiene-isoprene copolymer rubber (TBIR), the molar content of butadiene unit is 19.3%, Mooney viscosity ML(3+4, 100°C)= 72.2; natural rubber (NR), grade SMR 20, origin: Malaysia. White carbon black, ZEOSIL 1165MP by precipitation method, Rhodia, France.

[0033] The properties of the compositions disclosed in the examples were evaluated as described below. Based on the national standard GB / T 23651-2009, test the hardness of the vulcanized rubber at 23°C. Based on the national standard GB / T 528-2009, at 23°C, the tensile properties of the vulcanized rubber are tested with a dumbbell-shaped sample, and the elongation is measured at 100% (MA100) and 300% (MA300). Stress (MPa) . Based on the national standard GB / T 529-2008, the right-angle tear performance of the vulcanized rubber was tested at 23°C with a right-angle sample. Based on the national st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com