Mould-proof and antibacterial negative ion medium density fiberboard and preparation method thereof

An anti-mildew, antibacterial, and negative ion technology, applied in the field of building and decoration materials, can solve problems such as harmful to health, the production of mold, and the breeding of bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

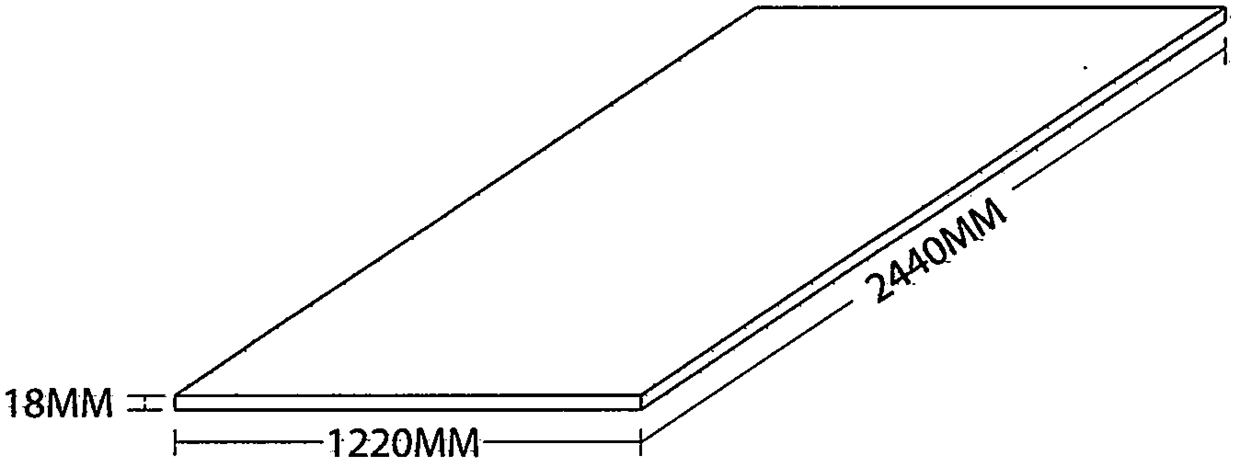

Image

Examples

Embodiment 1

[0012] A kind of mildewproof and antibacterial negative ion medium density fiberboard described in this embodiment is characterized in that it comprises 0.5 parts of OBPA, 0.5 parts of nano-silver powder, 2 parts of negative ion powder, 1 part of preservative, 90 parts of wood fiber, 15 parts of adhesive, and 5 parts of auxiliary agent. share.

[0013] A kind of mildew-proof and antibacterial negative ion medium density fiberboard described in this embodiment also includes the following steps: 1. chipping: mainly cutting pine wood into wood chips that meet the production specifications; 2. heat grinding: mainly preheating and cooking the wood chips and then separating Machine separation to obtain wood fiber, 3 sizing and drying: the temperature of the dryer is controlled at 150-200 degrees, and the wood fiber is dried to a moisture content between 8% and 10%, 4 mixed paving: through the feeding fan The paving machine adopts the method of vacuum airflow to preliminarily shape t...

Embodiment 2

[0016] A kind of mildewproof and antibacterial negative ion medium density fiberboard described in this embodiment is characterized in that it includes 1 part of OBPA, 1 part of nano silver powder, 3 parts of negative ion powder, 2 parts of preservatives, 100 parts of wood fiber, 16 parts of adhesive, and 6 parts of auxiliary agent share.

[0017] A kind of mildew-proof and antibacterial negative ion medium density fiberboard described in this embodiment also includes the following steps: 1. chipping: mainly cutting pine wood into wood chips that meet the production specifications; 2. heat grinding: mainly preheating and cooking the wood chips and then separating Machine separation to obtain wood fiber, 3 sizing and drying: the temperature of the dryer is controlled at 150-200 degrees, and the wood fiber is dried to a moisture content between 8% and 10%, 4 mixed paving: through the feeding fan The paving machine adopts the method of vacuum airflow to preliminarily shape the mi...

Embodiment 3

[0020] A kind of mildewproof and antibacterial negative ion medium density fiberboard described in this embodiment is characterized in that it comprises 3 parts of OBPA, 3 parts of nano silver powder, 4 parts of negative ion powder, 3 parts of preservatives, 110 parts of wood fiber, 18 parts of adhesive, 8 parts of auxiliary agent share.

[0021] A kind of mildew-proof and antibacterial negative ion medium density fiberboard described in this embodiment also includes the following steps: 1. chipping: mainly cutting pine wood into wood chips that meet the production specifications; 2. heat grinding: mainly preheating and cooking the wood chips and then separating Machine separation to obtain wood fiber, 3 sizing and drying: the temperature of the dryer is controlled at 150-200 degrees, and the wood fiber is dried to a moisture content between 8% and 10%, 4 mixed paving: through the feeding fan The paving machine adopts the method of vacuum airflow to preliminarily shape the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com