Processing method capable of improving the contact quality of bevel gear pair of K series speed reducer

A technology of bevel gear pair and processing method, which is applied in the field of deep processing of bevel gear pair, and can solve problems such as unsatisfactory effect and grid data reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

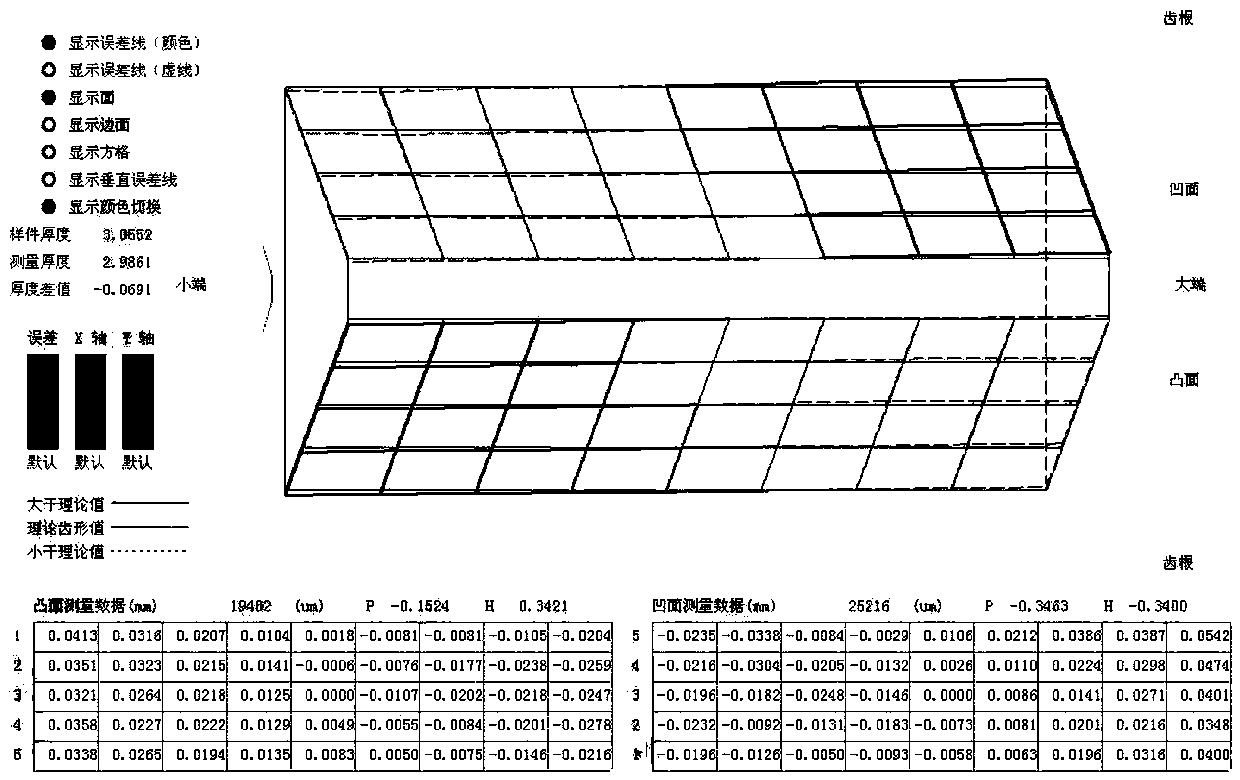

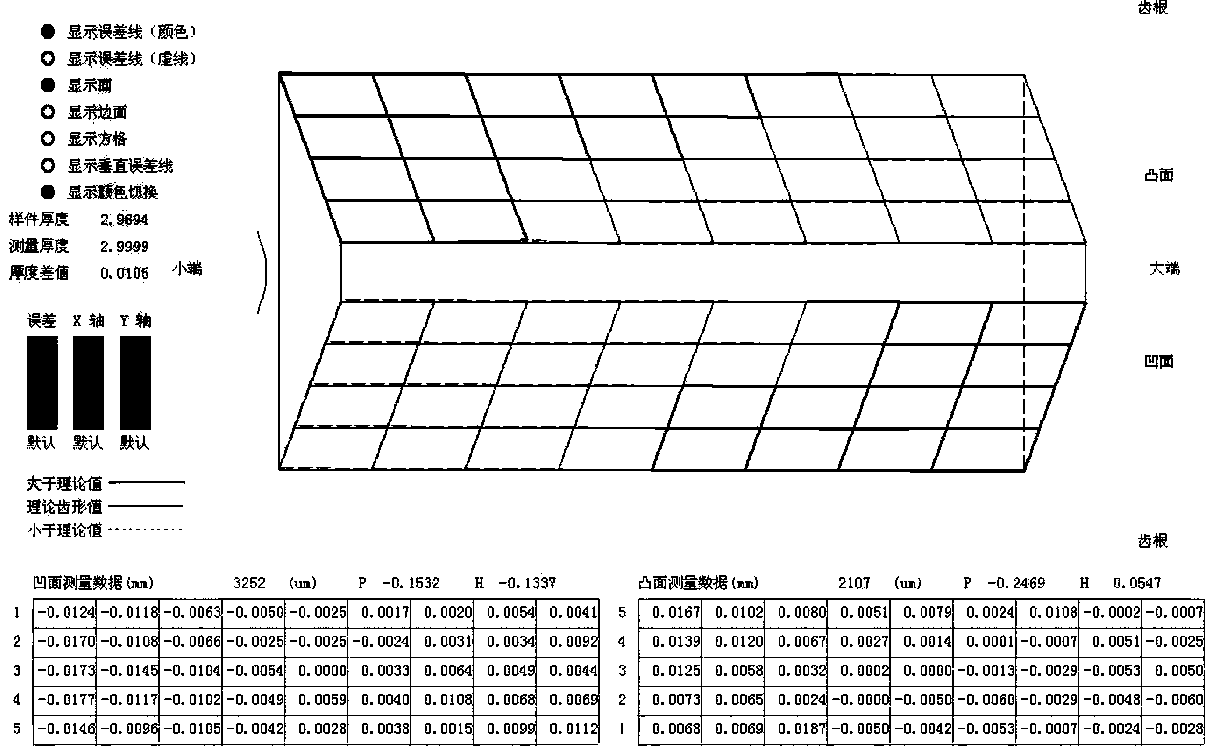

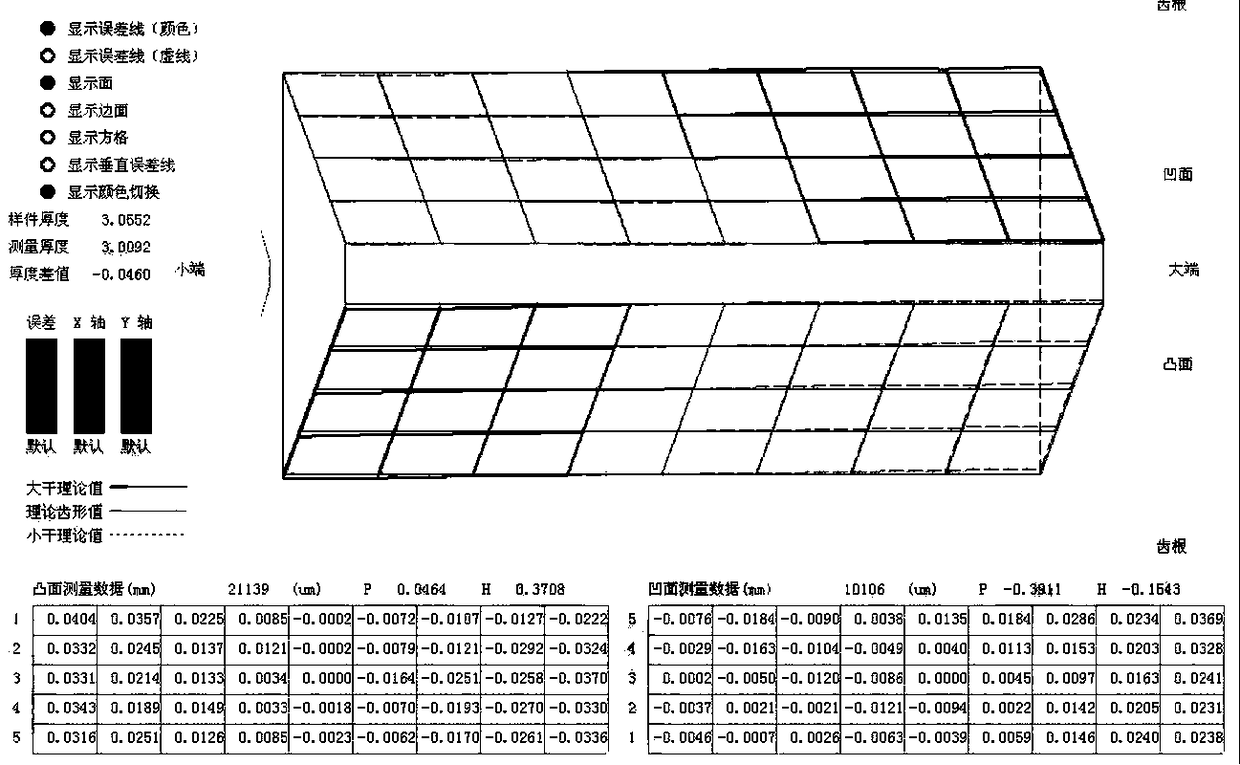

[0017] A processing method for improving the contact quality of the bevel gear pair of the K series reducer. The specific steps are as follows: the method of pre-adjusting the contact area is adopted, and the relevant parameters are pre-adjusted before the heat treatment, taking into account the tooth shape change rule after heat treatment. The eccentric angle is reduced by 20 minutes, so that the heat-treated tooth profile is in the ideal position on the tooth surface. The processing method can effectively modify the tooth surface contact area and improve the contact quality. The noise of the bevel gear pair processed by this processing method is 2-4db lower than that of the bevel gear pair processed by the traditional method of grinding and correcting the contact area. After usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com