Reverse circulation pile driver

A technology of pile driver and reverse circulation, which is applied to sheet pile walls, drilling equipment, earthwork drilling, etc., can solve the problems of difference in wire rope length, increase in cost of pile drivers, and decrease in construction quality, so as to reduce construction errors and improve Work efficiency and service life, the effect of eliminating construction errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

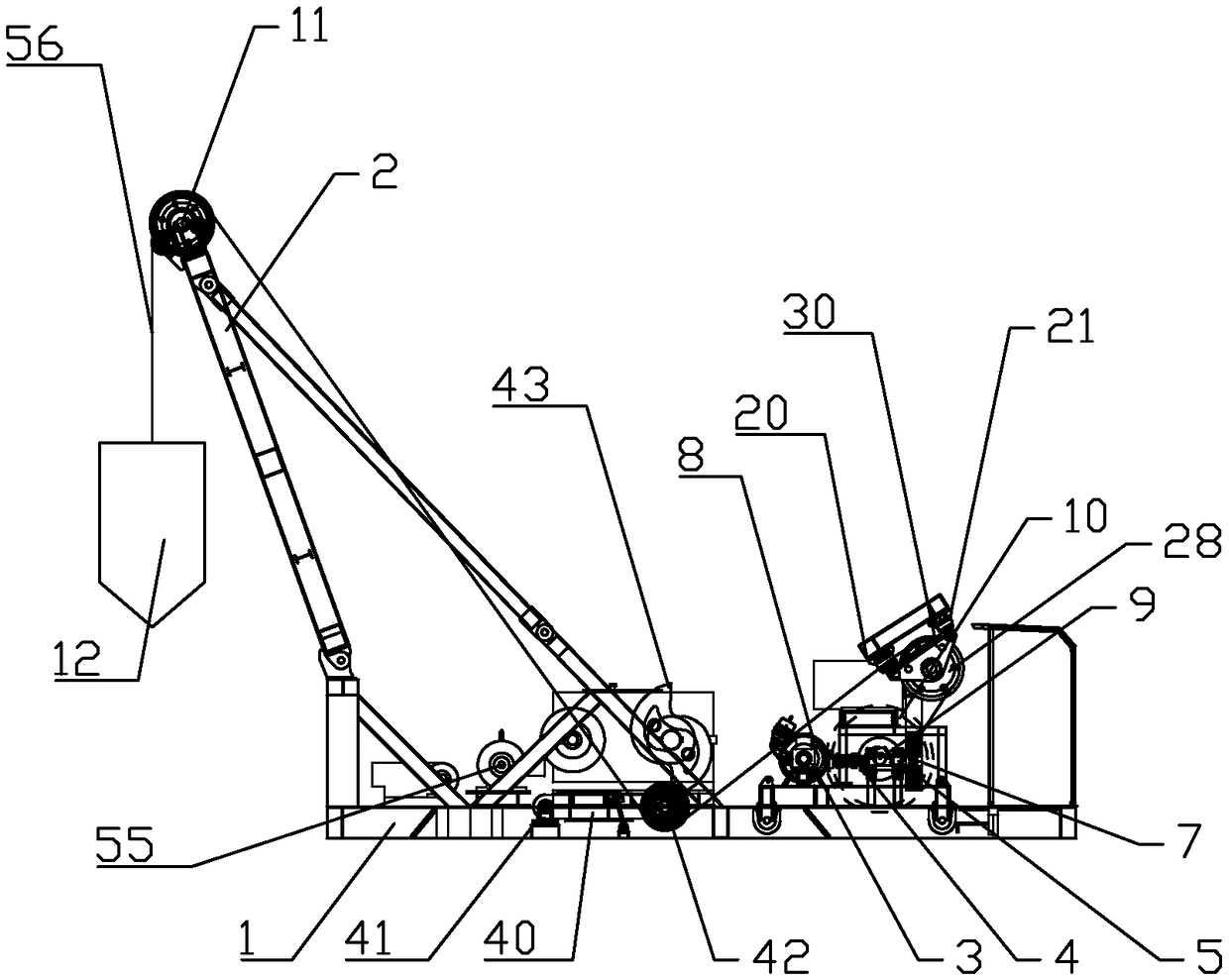

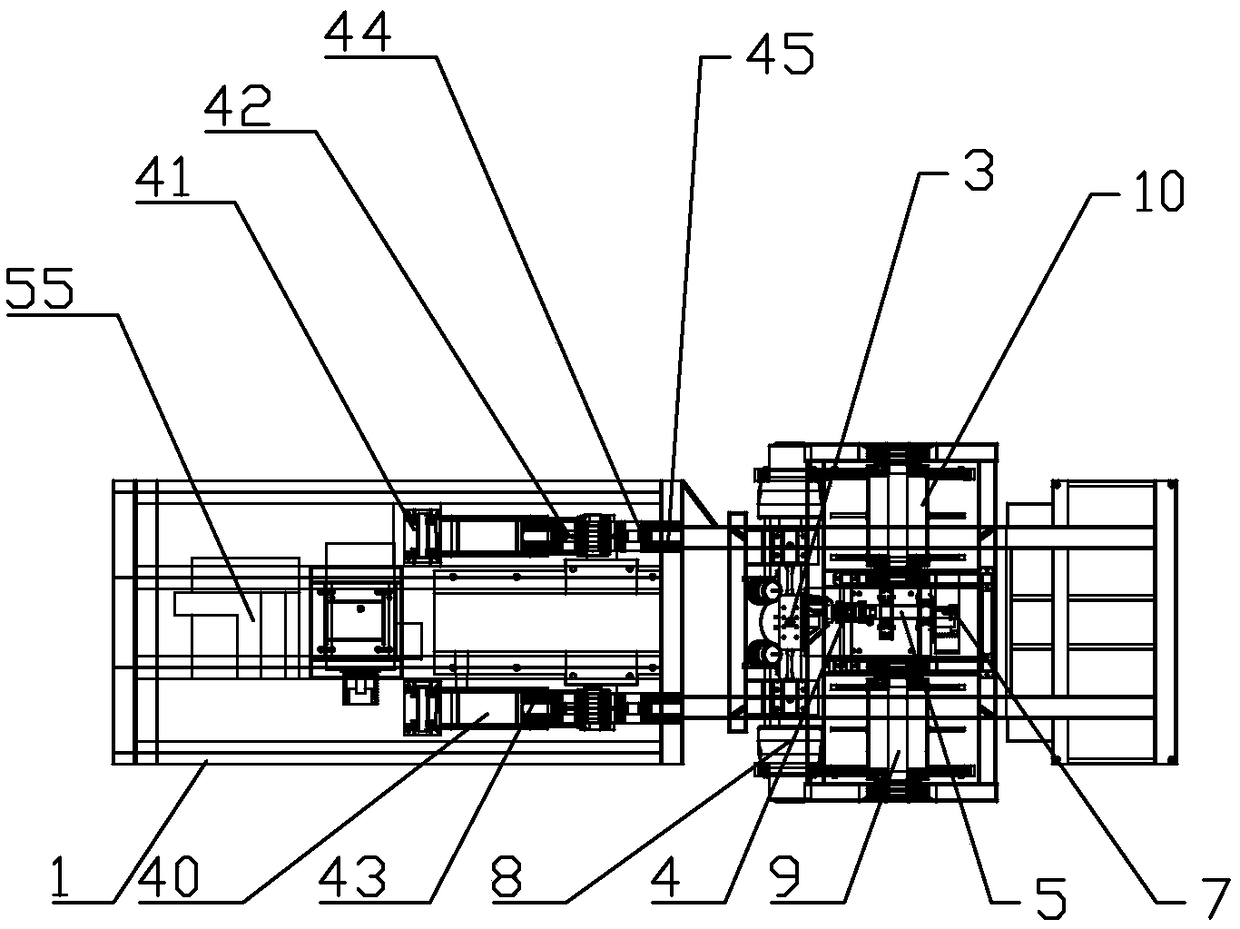

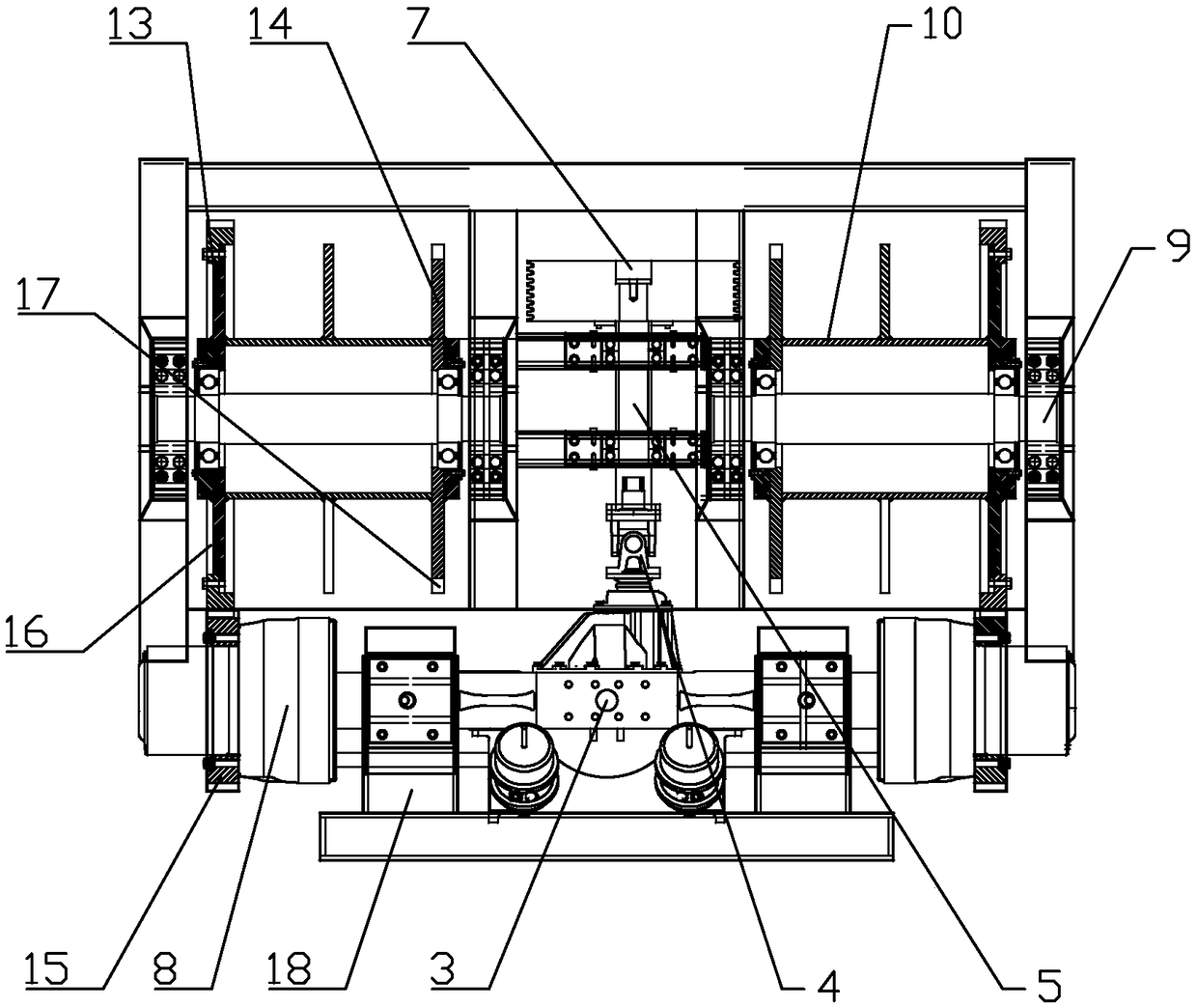

[0030] Such as Figure 1-12As shown in , a reverse circulation pile driver includes a base 1 and a frame assembly 2, a differential leveling mechanism is provided on the base 1, and a differential leveling mechanism is arranged on the frame assembly 2 above and behind the differential leveling mechanism. There are two swing-type wire rope sheave seats matched with the differential speed leveling mechanism, and two double-cam swing arm drive mechanisms matched with the two swing-type wire rope sheave seats are arranged at intervals on the base 1 on the front side of the differential speed leveling mechanism. The top of the frame assembly 2 is provided with a first wire rope pulley 11 matched with the two double-cam swing arm driving mechanisms, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com