Air floating piston for reciprocating type compressor

A compressor and reciprocating technology, applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of long procurement cycle and affecting the efficiency of natural gas production departments, and reduce the number of shutdowns and maintenance costs , easy processing and assembly, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

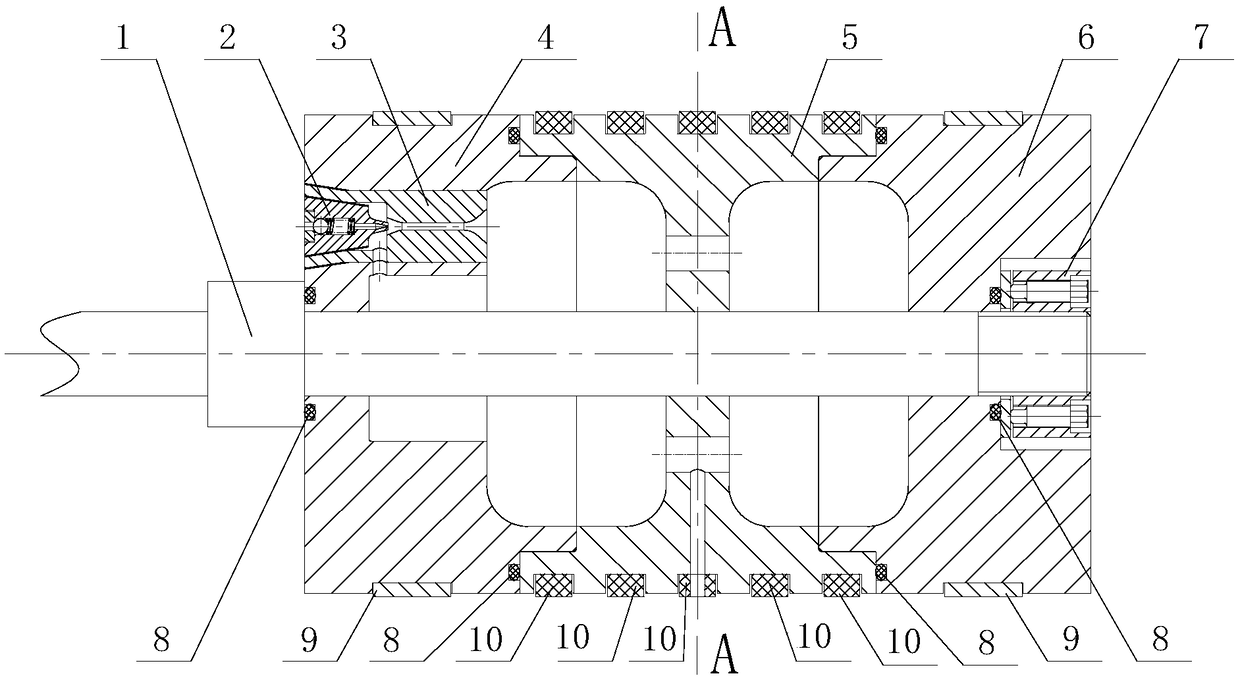

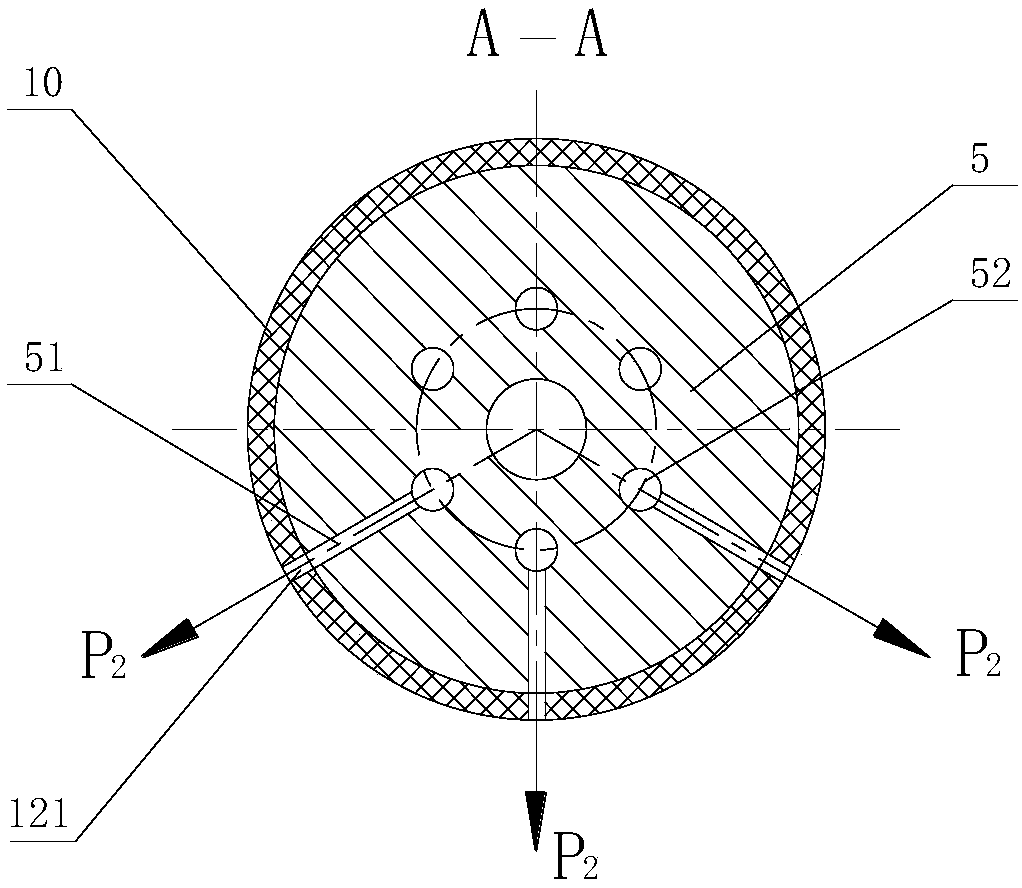

[0047] like Figure 1-7 As shown, the installation steps of the air-floating piston structure for the reciprocating compressor are as follows:

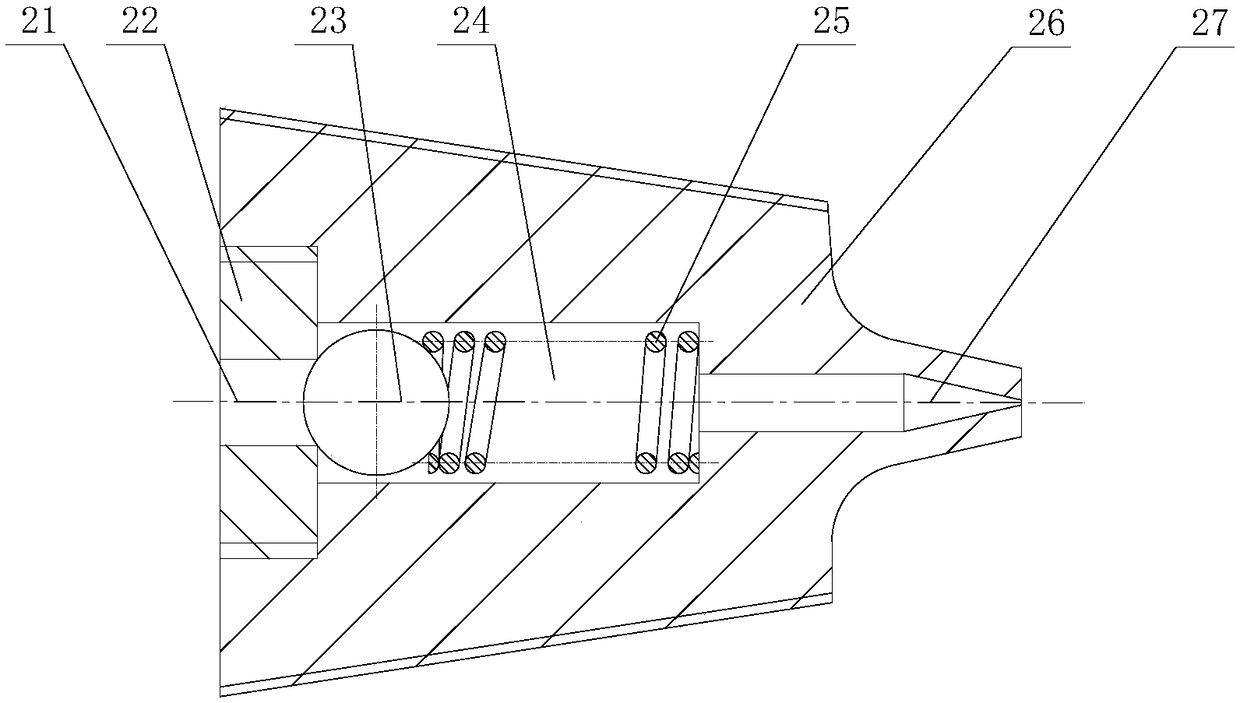

[0048] 1) Assemble the one-way valve part 2: fix the steel ball 23 and the spring 25 in the one-way valve chamber 24, and then thread the retaining ring 22 and the one-way valve body 26;

[0049] 2) Install the assembled one-way valve part 2 in the one-way valve part installation hole 31 in the Venturi tube 3, and connect with tapered threads;

[0050] 3) Install the Venturi tube 3 in the Venturi tube installation hole 401 of the piston front body 4 to ensure that the low-pressure and low-temperature air inlet hole of the Venturi tube 3 communicates with the low-temperature and low-pressure air outlet 404 of the piston front body 4;

[0051] 4) Install the scraper ring 9 in the scraper ring groove 402 of the front end body 4 of the piston, and respectively install the O-rings 8 in the seal ring grooves on the left end surface and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com