Test device for simulating grouting diffusion radius of gravel formation under dynamic water environment

A technology of diffusion radius and test device, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of grouting materials, low strength, inability to withstand high pressure of dynamic water, etc., to achieve smooth grouting diffusion, uniform pressure distribution, Use good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

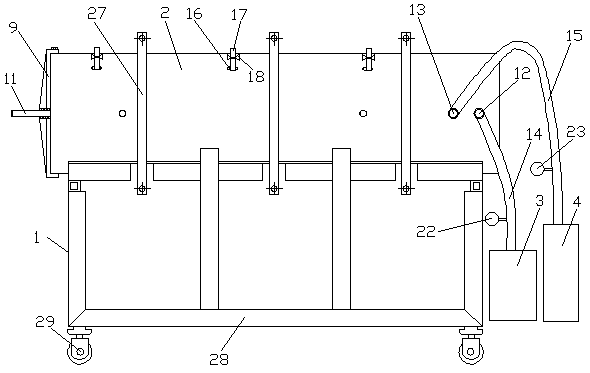

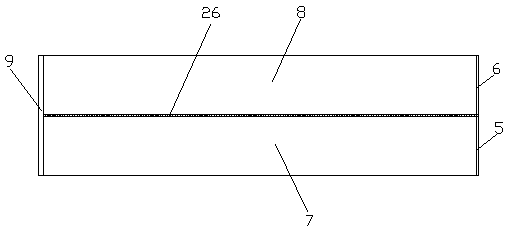

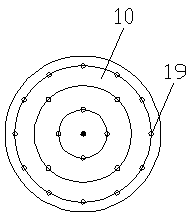

[0041] A test device for simulating the diffusion radius of grouting in sandy gravel formations under a hydrodynamic environment, including a bracket 1 and a stainless steel box 2 for storing gravel samples, the stainless steel box 2 is fixed on the bracket 1, and a grouting pump 3 and The water injection pump 4, the stainless steel box 2 includes a first front end baffle 5, a second front end baffle 6, a first semicircular semi-closed pipe 7, a second semicircular semi-closed pipe 8 and a rear end cover 9, The first semicircular semi-closed pipe 7 and the second semicircular semi-closed pipe 8 are detachably connected, the first front end baffle plate 5 is fixedly connected with the front end of the first semicircular semi-closed pipe 7, and the second front end Baffle plate 6 is fixedly connected with the front end of the second semicircular semi-closed pipe 8, and the rear end cover 9 is respectively connected with the rear end of the first semicircular semi-closed pipe 7 an...

Embodiment 2

[0044] A test device for simulating the diffusion radius of grouting in sandy gravel formations under a hydrodynamic environment, including a bracket 1 and a stainless steel box 2 for storing gravel samples, the stainless steel box 2 is fixed on the bracket 1, and a grouting pump 3 and The water injection pump 4, the stainless steel box 2 includes a first front end baffle 5, a second front end baffle 6, a first semicircular semi-closed pipe 7, a second semicircular semi-closed pipe 8 and a rear end cover 9, The first semicircular semi-closed pipe 7 and the second semicircular semi-closed pipe 8 are detachably connected, the first front end baffle plate 5 is fixedly connected with the front end of the first semicircular semi-closed pipe 7, and the second front end Baffle plate 6 is fixedly connected with the front end of the second semicircular semi-closed pipe 8, and the rear end cover 9 is respectively connected with the rear end of the first semicircular semi-closed pipe 7 an...

Embodiment 3

[0050] A test device for simulating the diffusion radius of grouting in sandy gravel formations under a hydrodynamic environment, including a bracket 1 and a stainless steel box 2 for storing gravel samples, the stainless steel box 2 is fixed on the bracket 1, and a grouting pump 3 and The water injection pump 4, the stainless steel box 2 includes a first front end baffle 5, a second front end baffle 6, a first semicircular semi-closed pipe 7, a second semicircular semi-closed pipe 8 and a rear end cover 9, The first semicircular semi-closed pipe 7 and the second semicircular semi-closed pipe 8 are detachably connected, the first front end baffle plate 5 is fixedly connected with the front end of the first semicircular semi-closed pipe 7, and the second front end Baffle plate 6 is fixedly connected with the front end of the second semicircular semi-closed pipe 8, and the rear end cover 9 is respectively connected with the rear end of the first semicircular semi-closed pipe 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com