Method for rapidly detecting broken rice rate based on image recognition

A detection method and broken rice rate technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of low classification accuracy, large errors, large randomness, etc., and achieve easy image processing, fast The effect of detecting and improving the accuracy of the results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

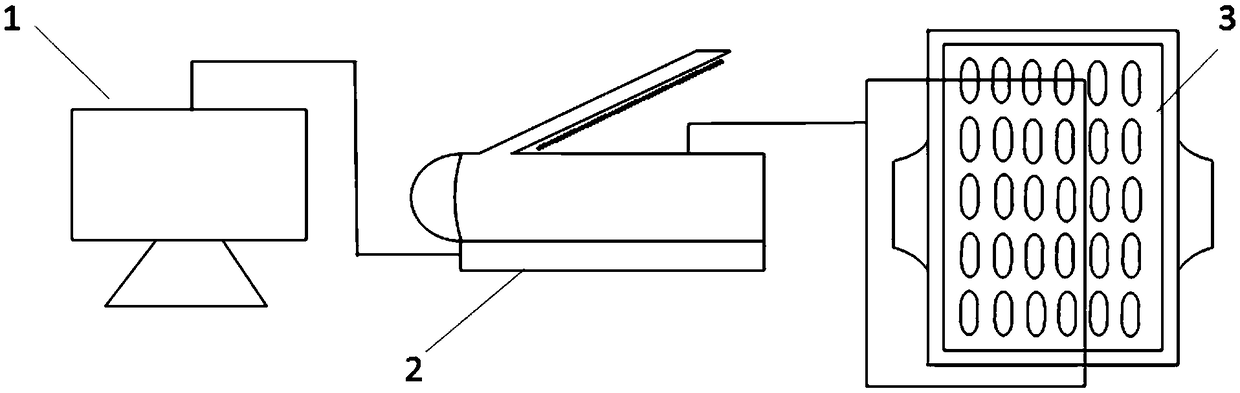

[0065] Such as Figure 1-5 Shown, a kind of detection device that is used for the appearance quality detection of rice, comprises display 1, scanner 2 and data processor and arrangement device; Described scanner 2 is connected with display 1, scan result is transmitted to display 1 and displayed on display The scanned image is displayed on 1. The scanner can be selected from models such as Lenovo M7206W all-in-one machine, and the data processor can be selected from Lenovo C560 microcomputer.

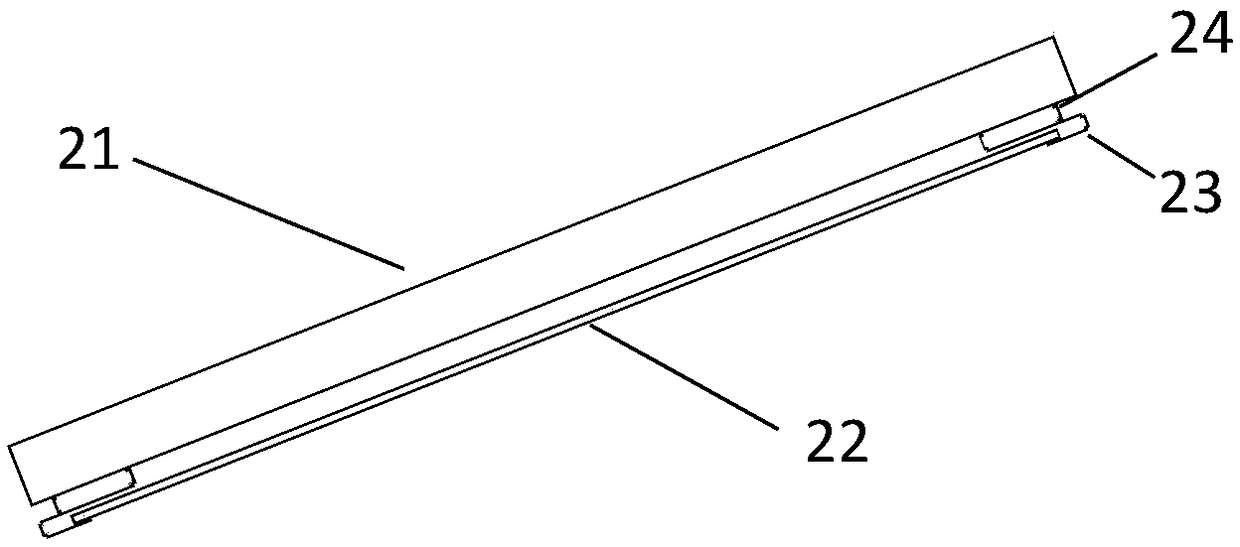

[0066] The inside of the cover plate 21 of the scanner 2 is provided with a detachable background plate 22; the background plate 22 is a solid color background plate, and the colors include but not limited to black, brown, purple; the background plate 22 is fixed on the cover plate 21 by a fixing device Inside; the fixing device is provided with at least 2; the fixing device is composed of a suction cup 24 and a draw-in groove 23 fixed on the sucker 24; the groove of the draw-in groove...

Embodiment 3

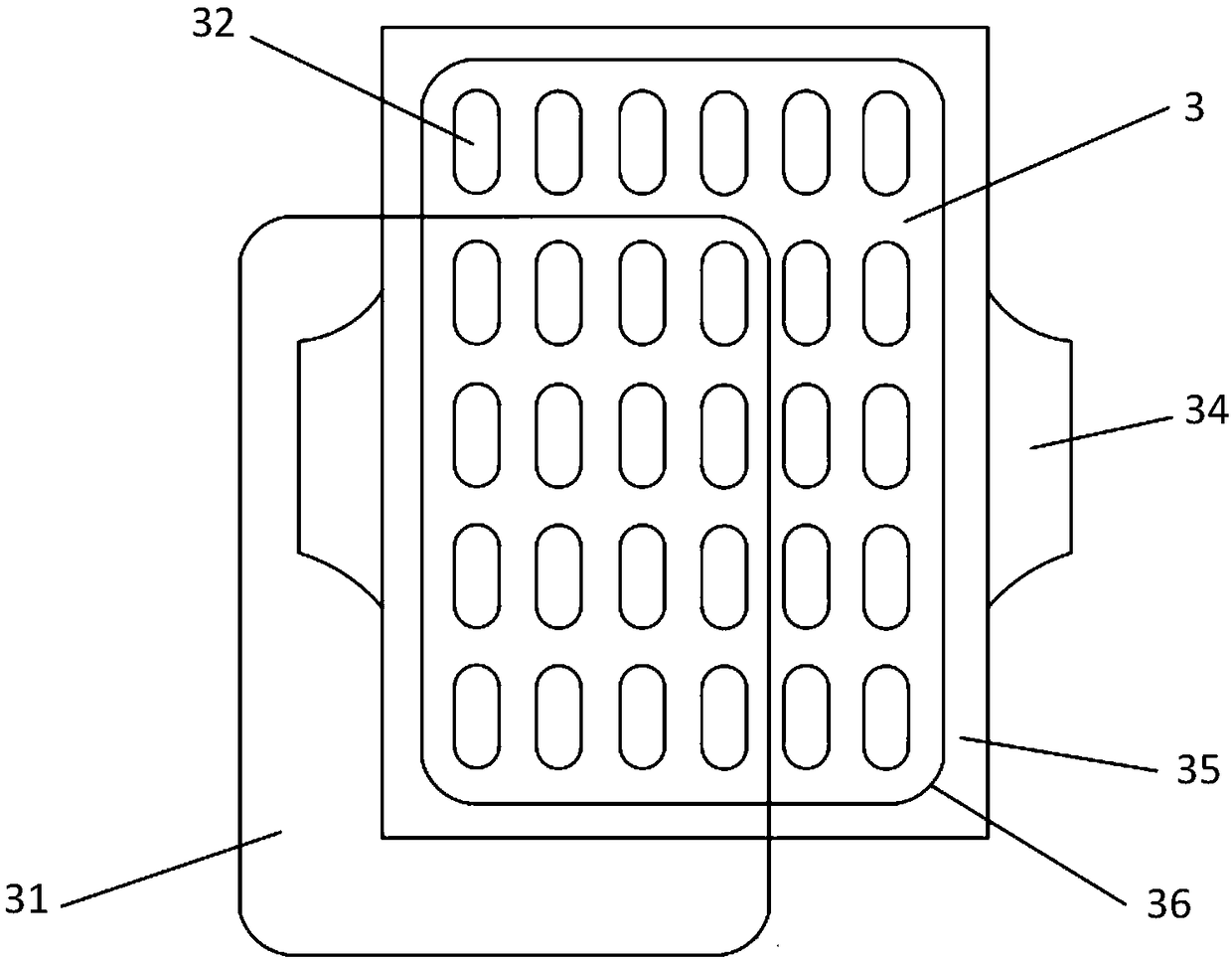

[0079] The rice sample is measured with the rice appearance quality detection system of Example 1. First place the orifice plate on a glass plate and fit tightly. Weigh a certain amount of rice (0-15g), put it evenly on the orifice plate, and gently shake the orifice plate and the glass plate until the rice particles are dispersed in different holes. After the rice is separated on the glass plate by the perforated plate, the entire array is gently placed on the scanner, the perforated plate is removed, and the scanner cover with the black background is closed. Open the software on the computer to scan the rice sample, after the scan is over, save the scanned rice sample picture in the designated folder; run the rice sample processing program in Example 1, perform operations on the designated picture, record the total number of rice, broken rice The parameter results of rice and small broken rice ( Figure 8 ). Figure 8 The left picture of the figure corresponds to a total ...

Embodiment 4

[0081] The image recognition method distinguishes broken rice and small broken rice by length. Before image processing, it is necessary to debug the detection program to determine the threshold of broken rice and small broken rice. The set threshold is the ratio of the length of broken rice and the length of small broken rice to the complete length of the same batch of rice. Depend on Figure 9 and Figure 10 It can be seen that the number of broken rice particles and the number of small broken rice particles both increase with the increase of the threshold value, that is, the larger the threshold value, the higher the proportion of broken rice length and small broken rice length to complete rice grains. , The greater the number of small broken rice.

[0082] In order to determine the optimal threshold value of the instrument method for the determination of broken rice and small broken rice, the instrument method was used to determine the value of broken rice particles and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com