A low-power TO-277 package ultra-thin diode and a manufacturing method thereof

A TO-277, manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems affecting product life and reliability, thick body, large space occupation, etc., to achieve molding The process is simple, the power loss is reduced, and the production efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation mode of the present invention is illustrated by specific specific examples below, and those who are familiar with this technology can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

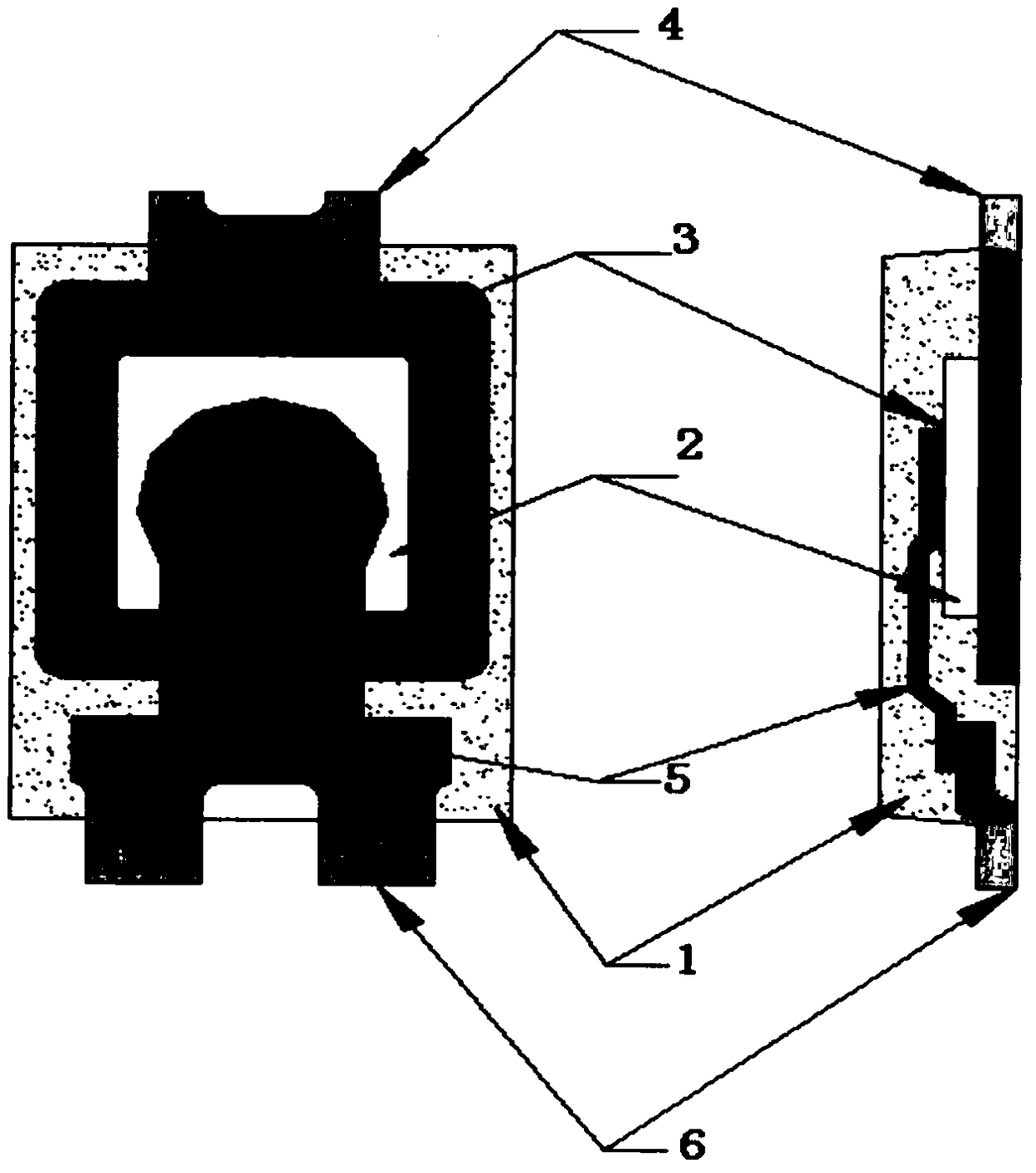

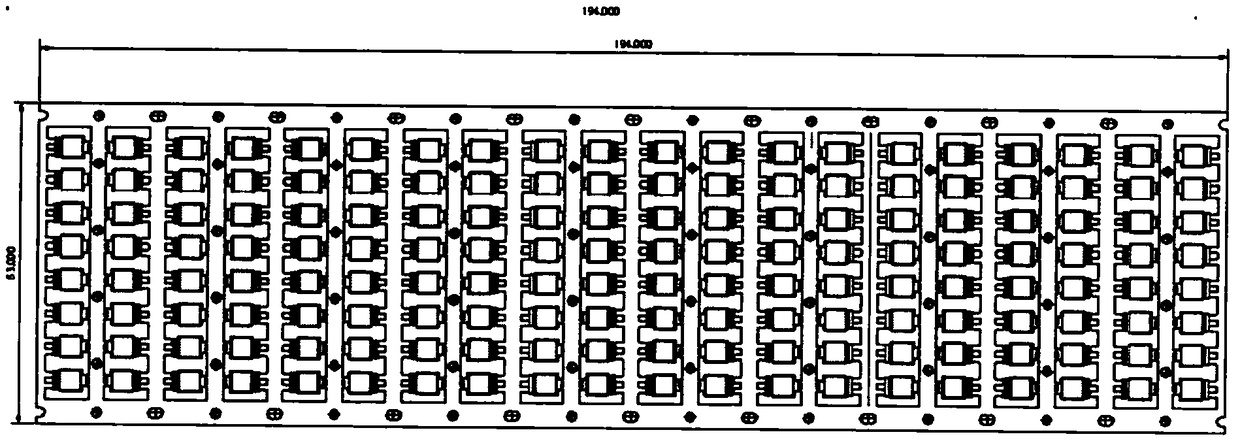

[0022] The invention provides a low-power consumption TO-277 package ultra-thin diode product, figure 1 It is a diagram of the low-power consumption TO-277 package ultra-thin diode product of the present invention, 01-plastic package, 02-chip, 03-solder, 04-material, 05-jumper, 06-tinning. figure 2 It is a diagram of a matrix material of the low-power consumption TO-277 packaged ultra-thin diode product of the present invention. The chip, solder, jumper wire and part of the material are packaged in the black plastic package, and the part of the material is extended to the black plastic package as a pin, and the surface of the pin is tinned to facilitate welding. The cross-section of the plastic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com