An ultraviolet LED quartz lens assembly structure and method

A quartz lens and assembly structure technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as increased production costs, strict vacuum requirements, lens shedding, etc., to improve work efficiency, increase contact surface, Applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

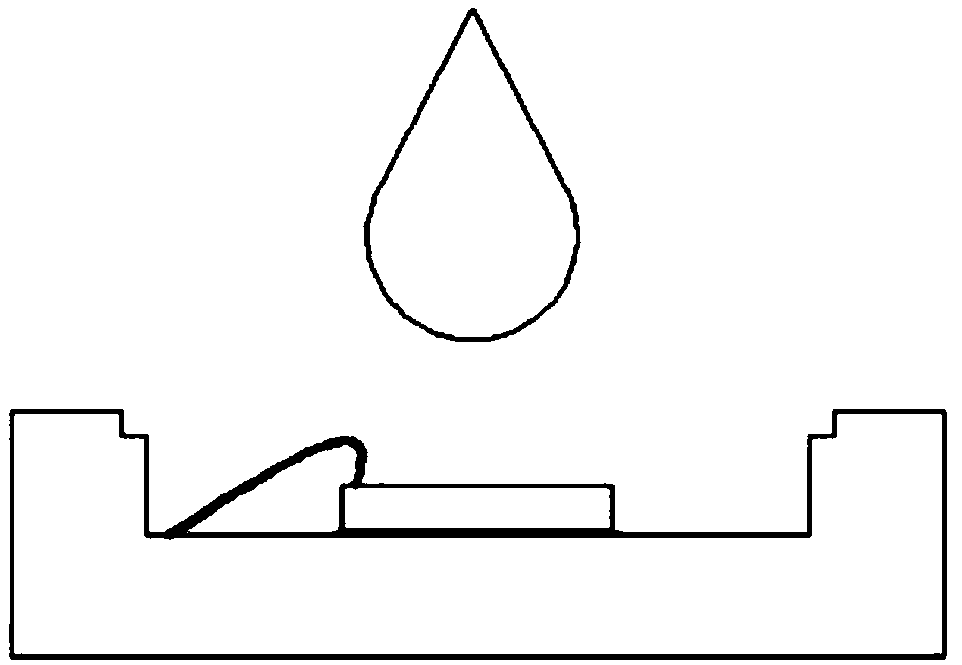

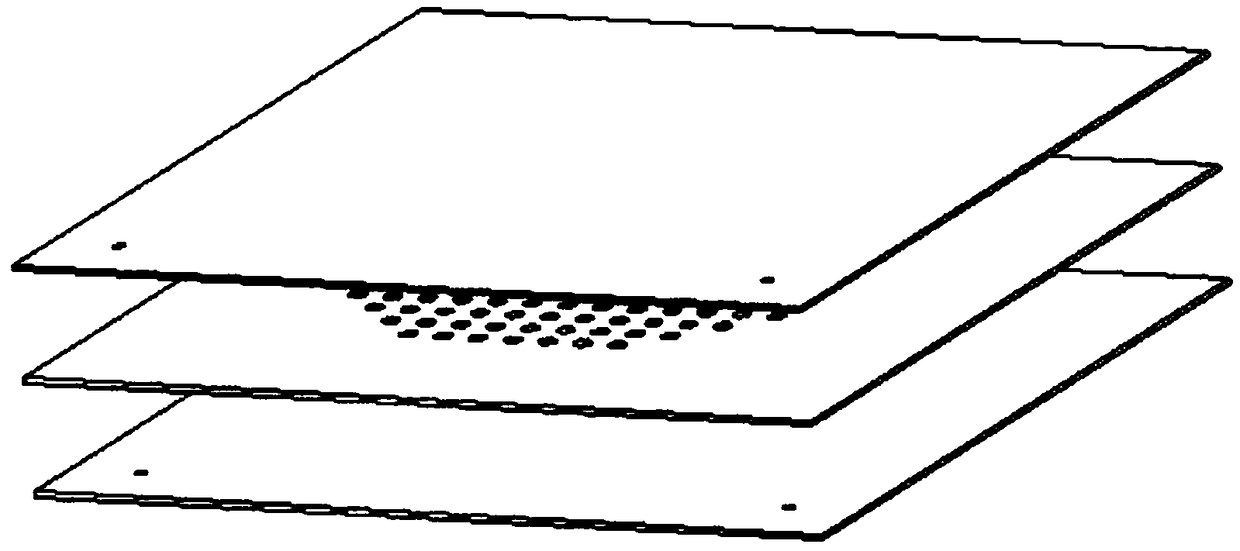

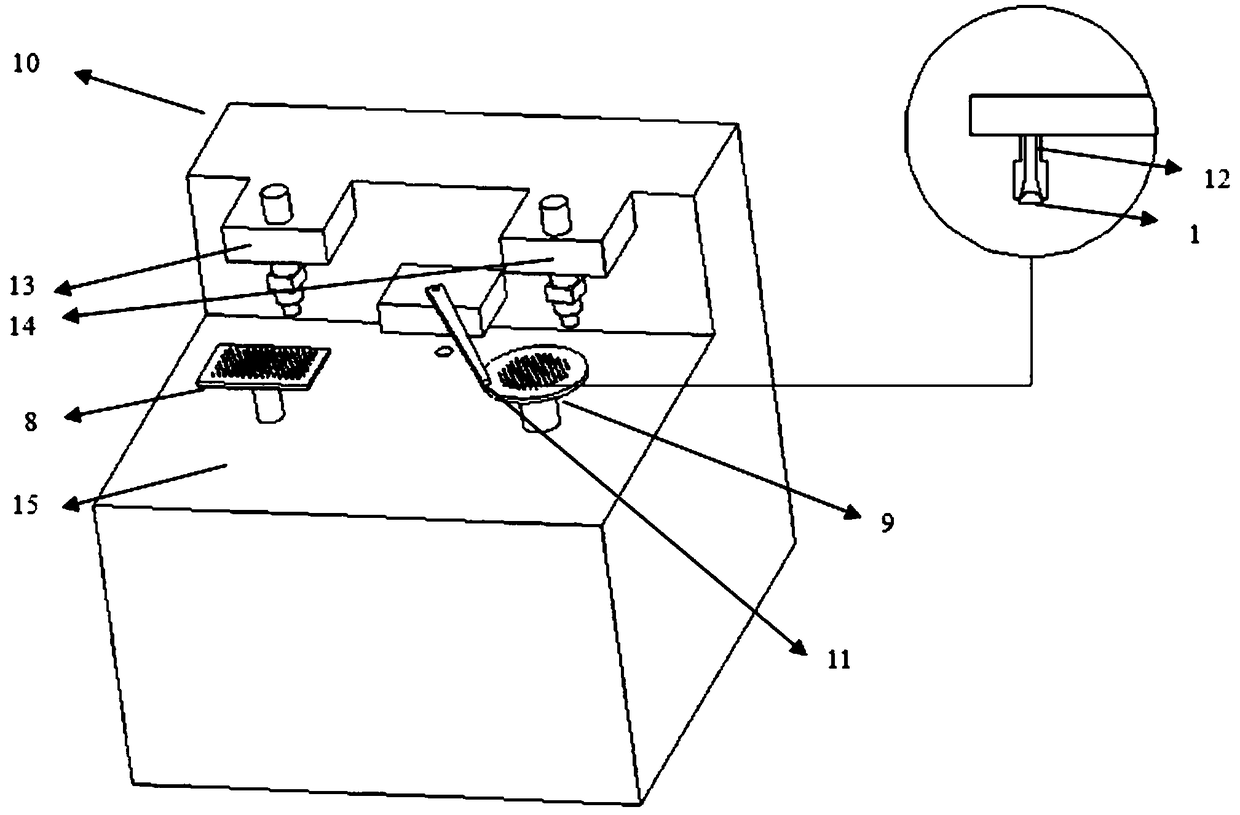

[0031] The present invention will be further described below in conjunction with the drawings:

[0032] The present invention includes an LED bracket 8 and a lens ring 9. The LED bracket 8 and the lens ring 9 are respectively arranged on the left and right sides of the front part of the dispensing workbench 15 of the die bonding machine 10. The LED bracket 8 is packaged with an ultraviolet LED chip 2 and a lens. Hemispherical quartz lenses 1 are arranged in an array on the ring 9, a swing arm mounting seat is provided at the center of the back of the glue dispensing work table 15 of the die bonder 10, and a swing arm 11 is rotatably connected to the swing arm mounting seat. The other end of the swing arm 11 is equipped with a suction nozzle 12. The suction nozzle 12 is made of hard plastic. The suction nozzle 12 is designed as a conical opening. The LED bracket 8 and the lens ring 9 are respectively equipped with a CCD camera 13 and a CCD camera. Two 14: CCD camera one 13 and CCD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com