A microstrip vertical transition structure

A vertical transition, microstrip technology, applied in electrical components, connecting devices, circuits, etc., can solve the problems of narrow relative bandwidth, complex processing, parasitic effects, etc., achieve wide relative bandwidth, meet the requirements of height and transmission frequency band, reduce The effect of parasitic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

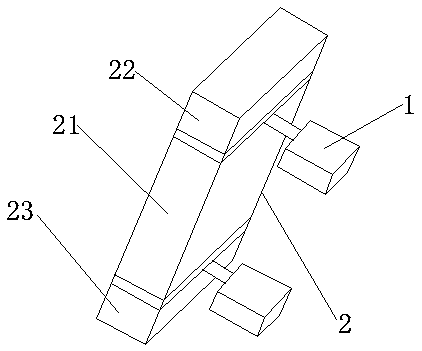

[0038] Such as figure 1 , the present invention is a microstrip vertical transition structure, including a microstrip section and a waveguide section 2; the microstrip section includes two microstrip boards 1, which are respectively inserted into the waveguide section 2 with a window in the center of the broadside.

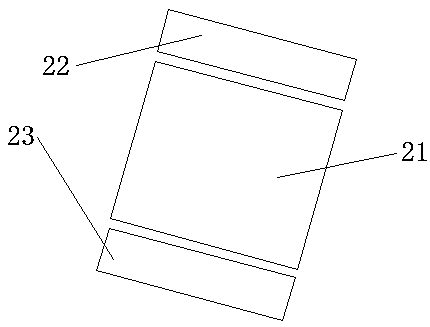

[0039] Such as figure 2 , the waveguide section 2 includes a waveguide cavity main body 21, and a waveguide cavity upper cover plate 22 and a waveguide cavity lower cover plate 23 respectively fastened with both ends of the waveguide cavity main body 21; A microstrip plate 2 is provided between the cover plate 22 and the lower cover plate 23 of the waveguide cavity.

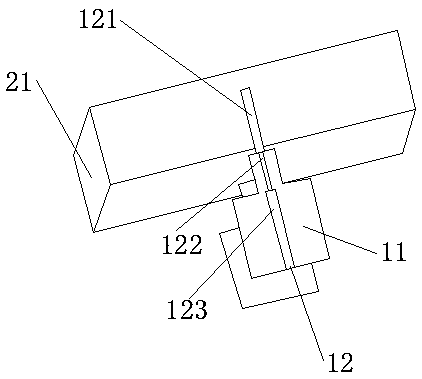

[0040] Such as image 3 , the microstrip board 1 includes a microstrip dielectric substrate 11, and a microstrip line 12 arranged on the top layer of the microstrip dielectric substrate 11; the microstrip dielectric substrate 11 is a four-layer PCB, and the top layer is etched as a microstrip line...

Embodiment 2

[0044] Such as Figure 4 , the present embodiment discloses a microstrip vertical transition structure, the waveguide cavity upper cover 22 and the waveguide cavity lower cover 23 respectively buckled at both ends of the waveguide cavity main body 21, and the waveguide cavity main body 21 and the waveguide cavity upper cover 22 respectively A microstrip dielectric substrate 11 is installed on the cross-section between the lower cover plate 23 of the waveguide cavity, and a microstrip dielectric substrate 11 is provided with a microstrip line 12, and the microstrip line 12 is respectively connected to an input joint and an output joint; The upper cover plate 22 of the waveguide cavity, the lower cover plate 23 of the waveguide cavity and the microstrip dielectric substrate 11 are fixed through the screw holes 222 .

[0045] Such as Figure 5 , the two ends of the waveguide cavity main body 21 are respectively provided with a microstrip dielectric substrate 11, the microstrip d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com