Process device for determining performance of charcoal cloth for removing malodorous gas

A technology for malodorous gas and process equipment, which is applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of undetermined accumulation height and uneven gas distribution, and achieves the effect of good sealing and uniform gas distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

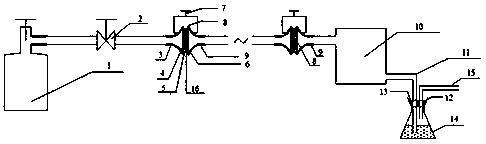

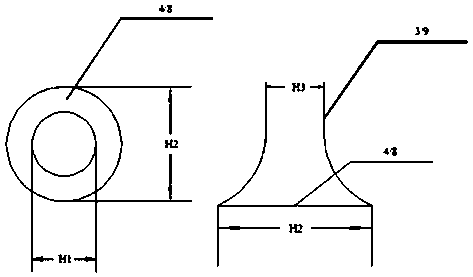

[0033] Such as figure 1 and figure 2A process device for measuring the performance of carbon cloth for removing malodorous gases is shown, including a hydrogen sulfide cylinder (1), a fine-tuning valve (2), a gas inlet and outlet unit, a gas chromatograph (10) and an exhaust gas absorption unit connected by a silicone tube. The air inlet and outlet unit described above includes an air inlet pipe (3) made of quartz, a first ring (4) made of quartz, a first silica gel pad (5), a second silica gel pad (6), and a second silica gel pad (6) made of quartz. Ring (8), outlet pipe (9) made of quartz, spherical clamp (7), the inlet pipe (3) made of quartz is a connecting pipe, the hydrogen sulfide cylinder (1) and the fine-tuning valve ( 2) Connected by a silicone tube, one end of the intake pipe (3) is the intake end, the fine-tuning valve (2) is connected to the intake end of the intake tube (3) through a silicone tube, the The first ring (4) is connected with the other end of the ...

Embodiment 2

[0047] Such as figure 1 and figure 2 A process device for measuring the performance of carbon cloth for removing malodorous gases is shown, including a hydrogen sulfide cylinder (1), a fine-tuning valve (2), a gas inlet and outlet unit, a gas chromatograph (10) and an exhaust gas absorption unit connected by a silicone tube. The air inlet and outlet unit described above includes an air inlet pipe (3) made of quartz, a first ring (4) made of quartz, a first silica gel pad (5), a second silica gel pad (6), and a second silica gel pad (6) made of quartz. Ring (8), outlet pipe (9) made of quartz, spherical clamp (7), the inlet pipe (3) made of quartz is a connecting pipe, the hydrogen sulfide cylinder (1) and the fine-tuning valve ( 2) Connected by a silicone tube, one end of the intake pipe (3) is the intake end, the fine-tuning valve (2) is connected to the intake end of the intake tube (3) through a silicone tube, the The first ring (4) is connected with the other end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com