Inlet flue triangular truss suspension type denitration reactor device

A denitrification reactor and inlet flue technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of not contributing to the force of the overall structure, not participating in the overall calculation, and increasing the load of the frame column. Achieve the effects of avoiding the limitations of stability and slenderness ratio, reducing the calculation length, and reducing the earthquake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

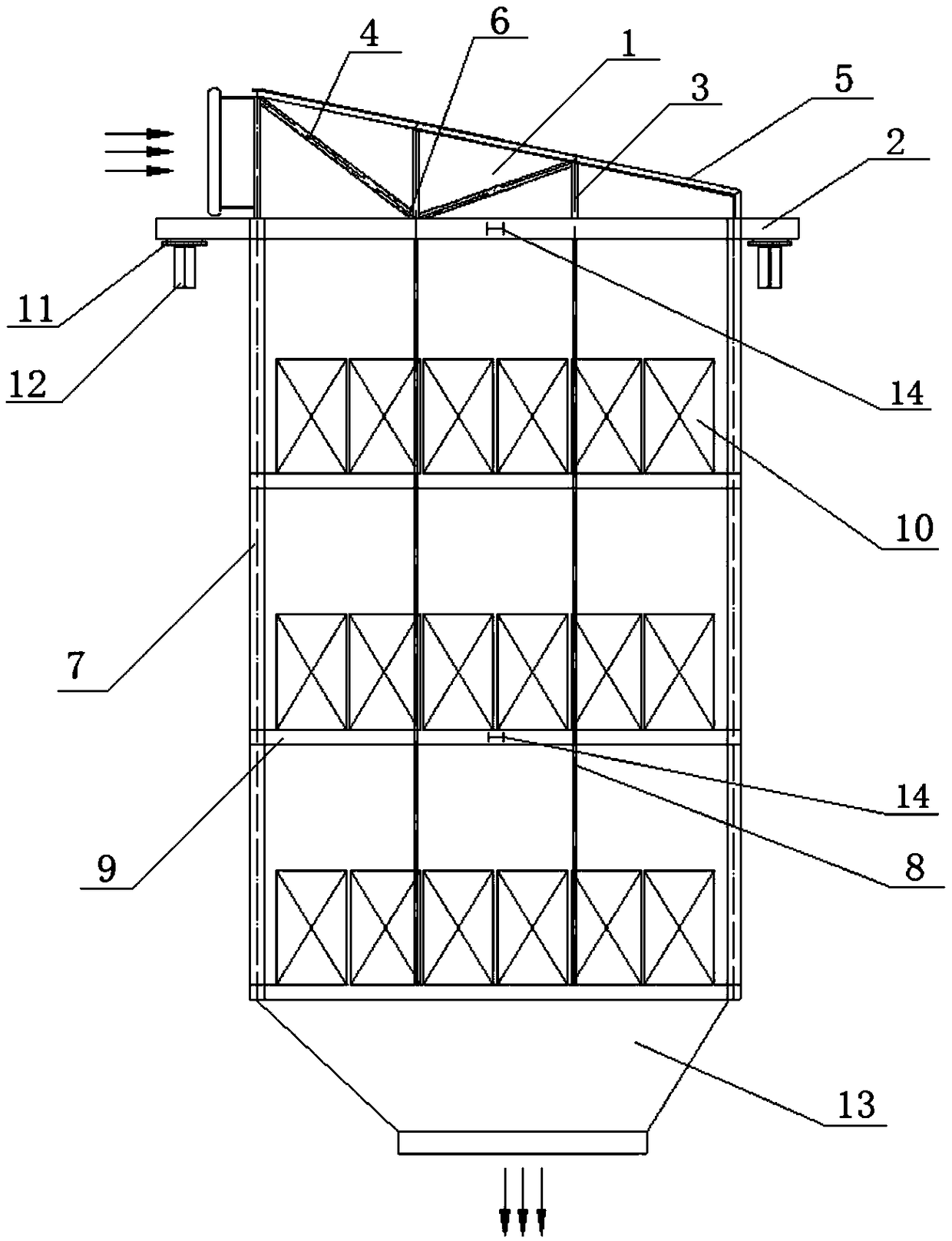

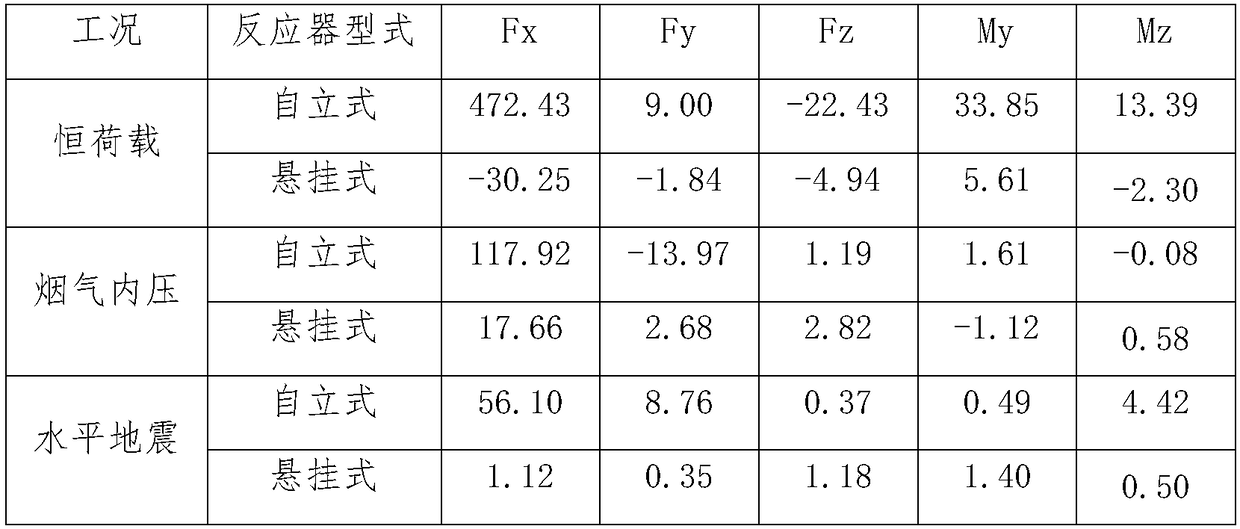

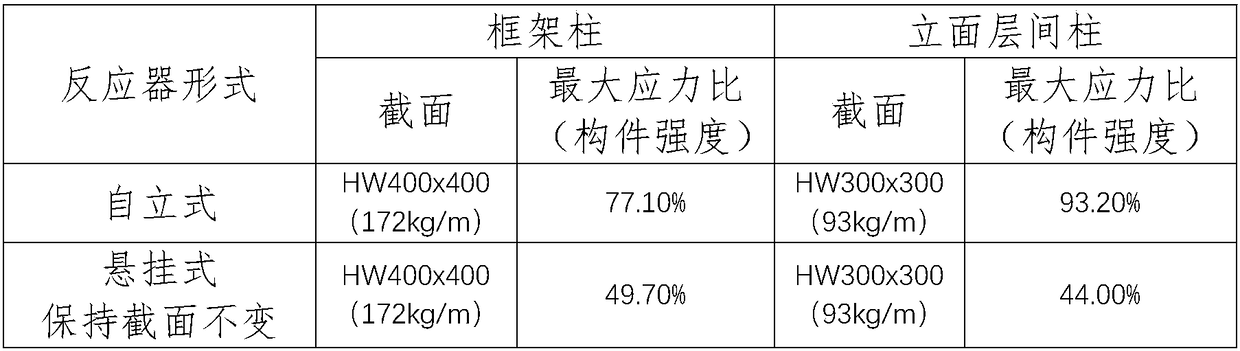

[0048] The SCR denitrification reactor device of an ironworks in Shanghai, the seismic fortification intensity of this project is 7 degrees, the design basic seismic acceleration value is 0.13g, the design earthquake grouping is the first group, the site category is second class, and the basic wind pressure is 0.40KN / m 2 ; The size of the denitrification reactor is 10.20m*6.60m*12.00m (height), and the height of the inlet flue is 1.65m. The overall model is calculated and subjected to force analysis in the structural design software, and finally the cross-sections of the triangular truss chord and the components of the denitrification reactor body are determined as follows: figure 1 shown.

[0049] During installation, the two ends of the support beam 2 (support rectification grid and inlet flue) on the top of the traditional denitrification reactor are extended to the peripheral steel support platform of the denitrification reactor as the lower chord of the triangular truss 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com