Rice flour grinding device for processing rice

A technology of a rice processing and grinding device, applied in grain processing and other directions, can solve the problems of insufficient uniformity and fineness of rice flour, easy aggregation and grinding of rice, and insufficient sufficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

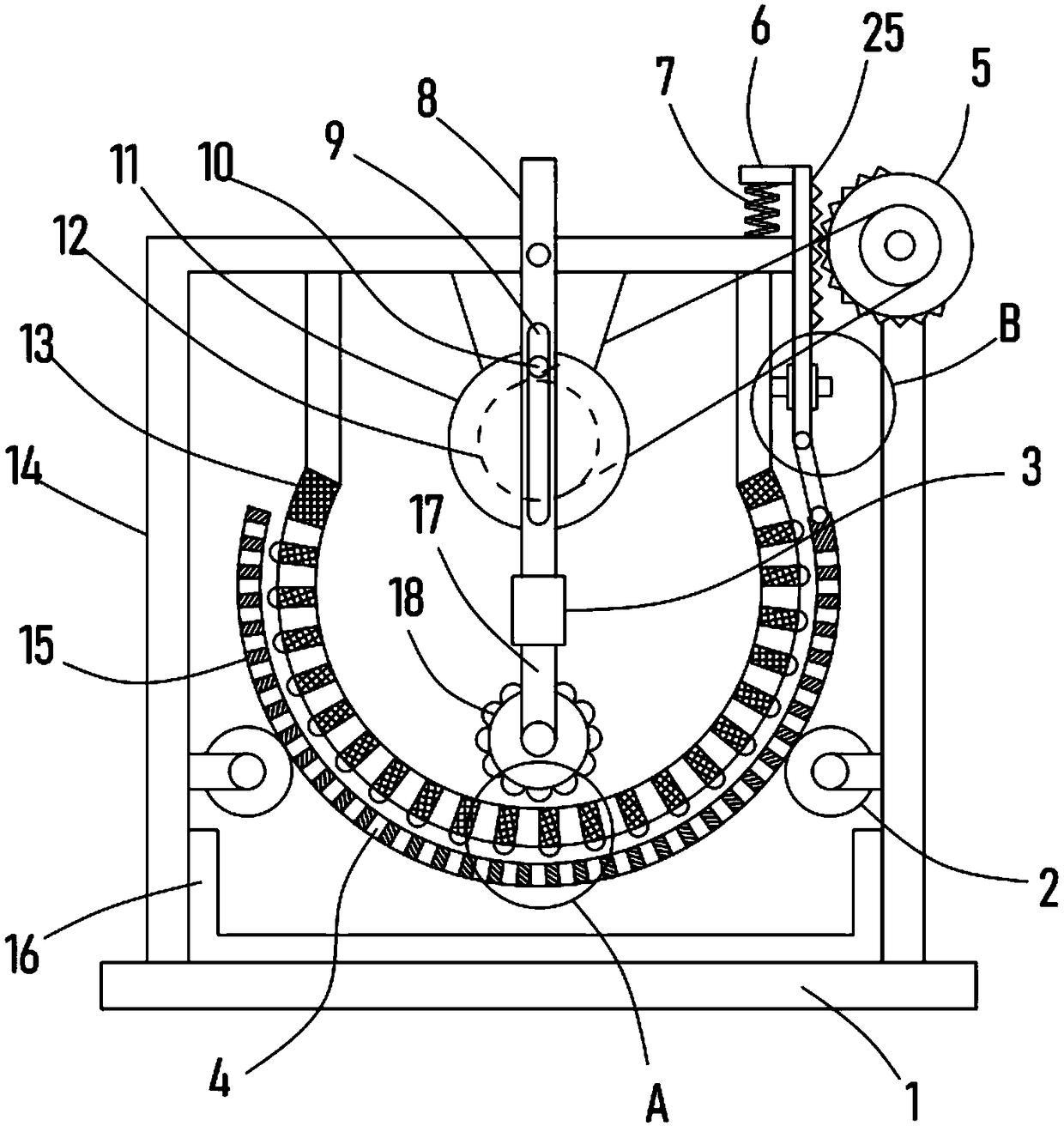

[0022] see Figure 1-4 , a rice flour grinding device for rice processing, comprising a base plate 1, the base plate 1 is fixed with a support frame 14, the support frame 14 is used for the main part of the device, and plays a load-bearing role, and the support frame 14 is rotatably provided with a rotating wheel 11, The rotating wheel 11 can be driven to rotate by being connected with a driving motor.

[0023] The support frame 14 is hinged with a fork 8, the fork 8 is provided with a waist-shaped hole 9, and the rotating wheel 11 is eccentrically fixed with a transmission pin 10 that slides through the waist-shaped hole 9. When the driving motor drives the rotating wheel 11 to rotate, The rotating wheel 11 drives the transmission pin shaft 10 arranged on it to rotate, and the transmission pin shaft 10 slides along the waist-shaped hole 9, thereby realizing the reciprocating swing of the swing rod 8 alternately clockwise and counterclockwise.

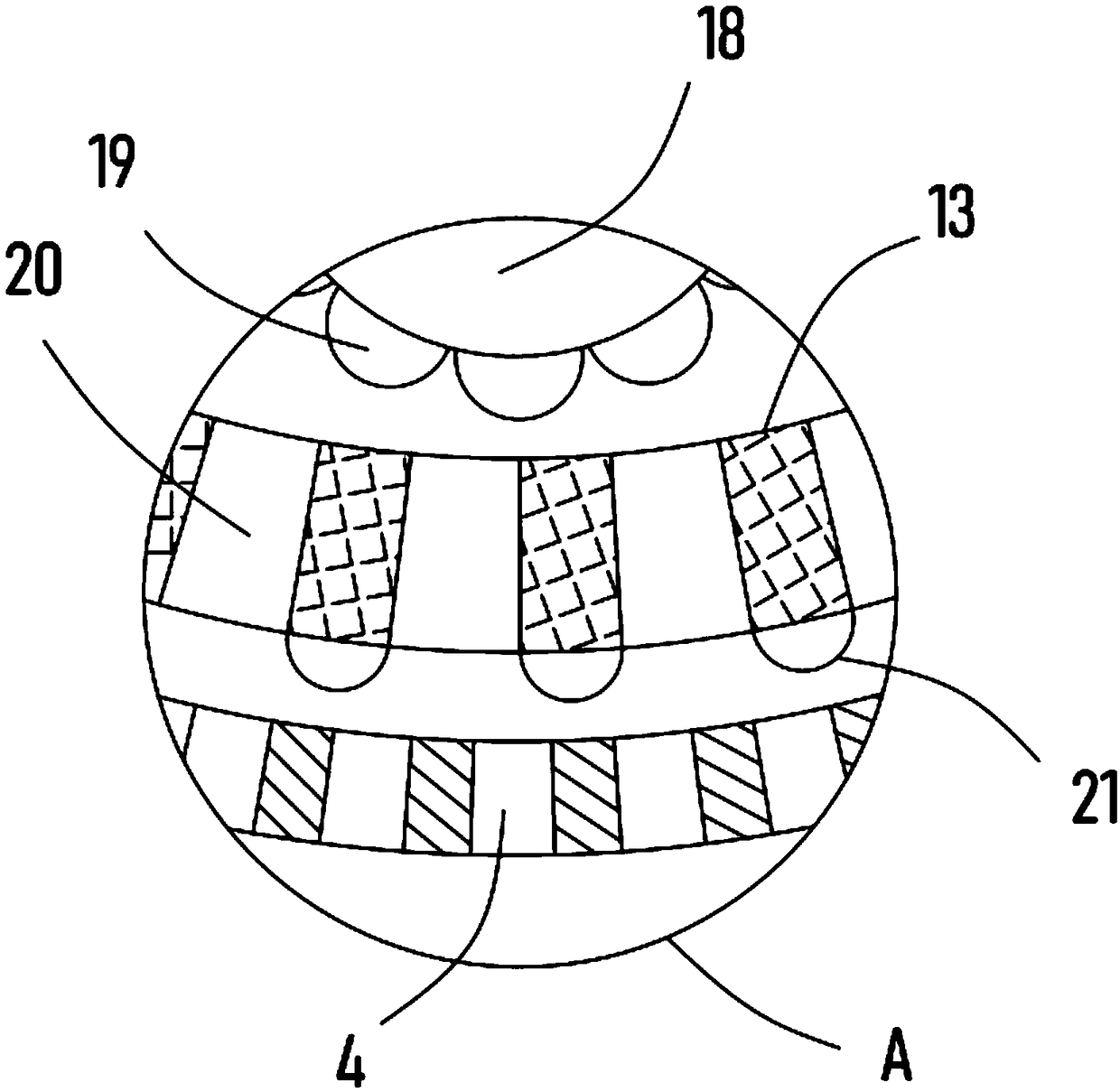

[0024] The arc-shaped first gr...

Embodiment 2

[0029] On the basis of Embodiment 1, in addition, the sliding sleeve at the lower end of the swing rod 8 is provided with a limit sleeve 3, and a sliding column 17 is slidably installed in the limit sleeve 3. The abutment spring 23 in the bit sleeve 3, the abutment spring 23 provided plays a role in pushing against the sliding column 17, ensuring that the grinding roller 18 is closely attached to the inner wall of the first grinding tank 13, ensuring sufficient grinding effect of the rice.

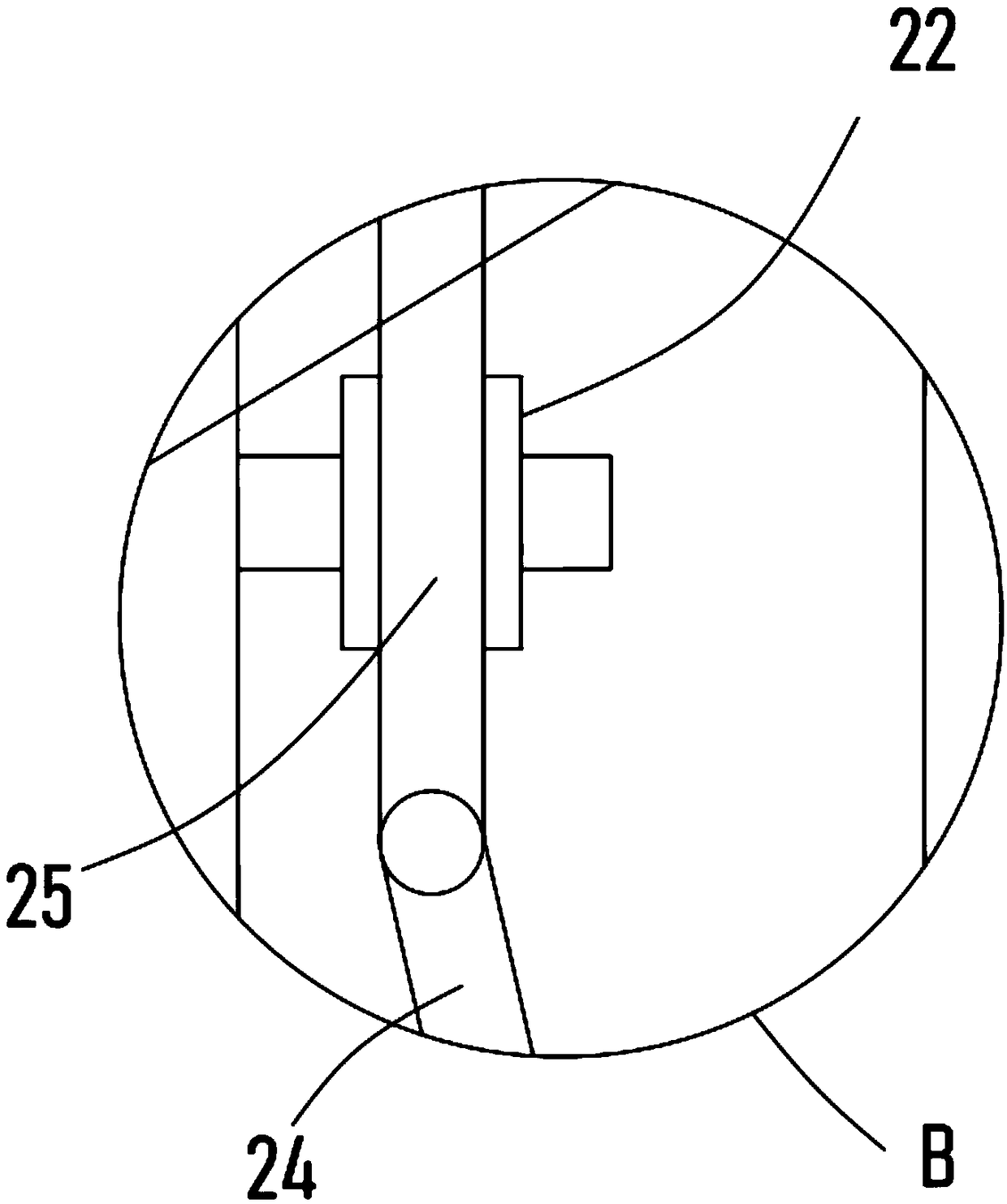

[0030] Further, the limit cover block 22 is fixed on the support frame 14, and the straight rack 25 is vertically slidably installed in the limit cover block 22, and the connecting rod 24 is hinged between the lower end of the spur rack 25 and the upper edge of the first grinding groove 13. , The supporting frame 14 is rotatably provided with an incomplete gear 5 meshing with the spur rack 25 .

[0031] Further, a belt pulley mechanism 12 is transmission-connected between the incomplete ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com