Waste lithium battery graded-crushing equipment and process

A waste lithium battery, graded crushing technology, applied in the direction of battery recycling, waste collector recycling, recycling technology, etc., can solve the problem of low separation efficiency, achieve obvious peeling effect, convenient physical sorting, and rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

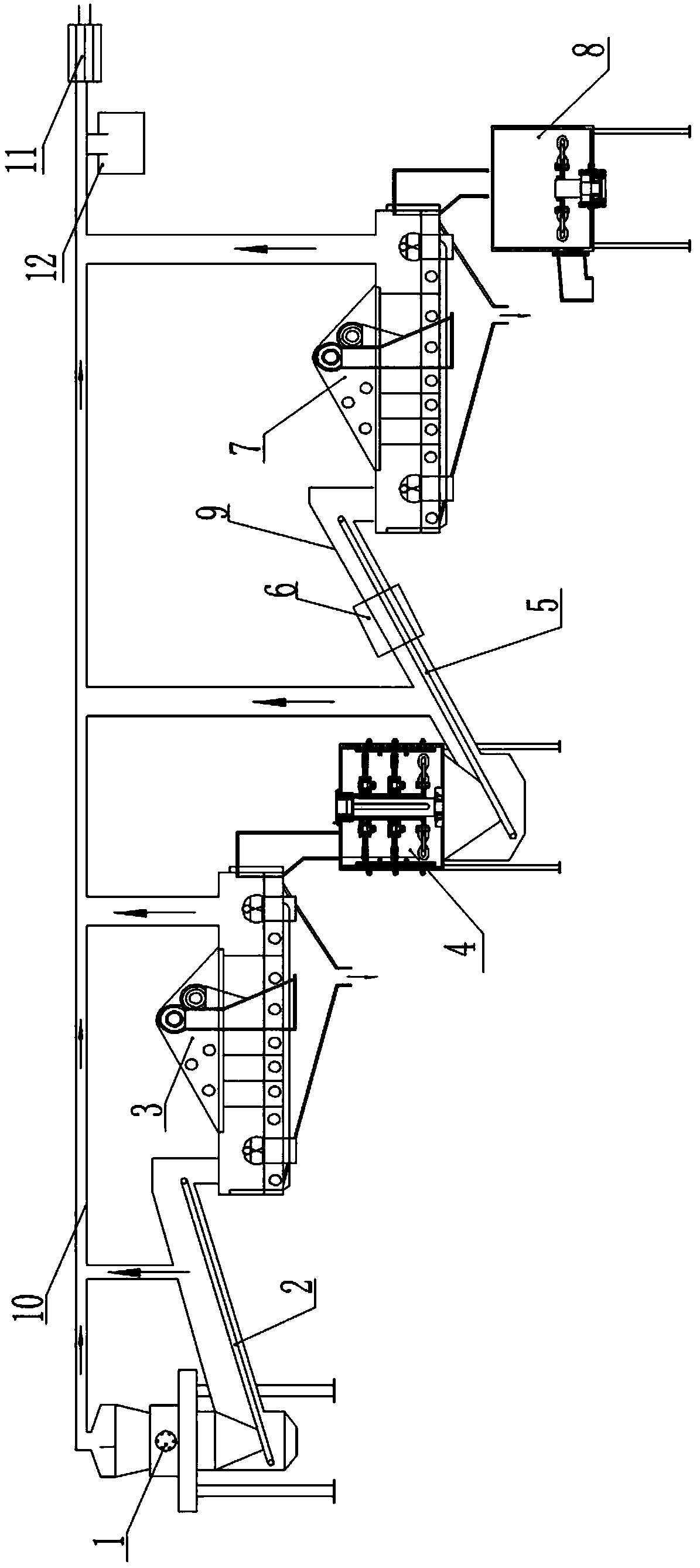

[0054] figure 1 Shown is a waste lithium battery classification and crushing equipment according to a preferred embodiment of the present invention, which includes a shredder 1, a primary transmission mechanism 2, a primary vibrating screen 3, a primary vertical crusher 4, and a secondary transmission mechanism 5 , magnetic separator 6, secondary vibrating screen 7, secondary vertical crusher 8, sealing cover 9, suction duct 10, suction fan 11 and diaphragm collector 12.

[0055] The first-level transmission mechanism 2 (conveyor belt can be used) is arranged obliquely. The lower end is the feeding end located below the discharge port at the bottom of the shredder 1, and the upper end is the discharging end. The discharge opening of the vibrating screen 3 is located above the primary vertical crusher 4 .

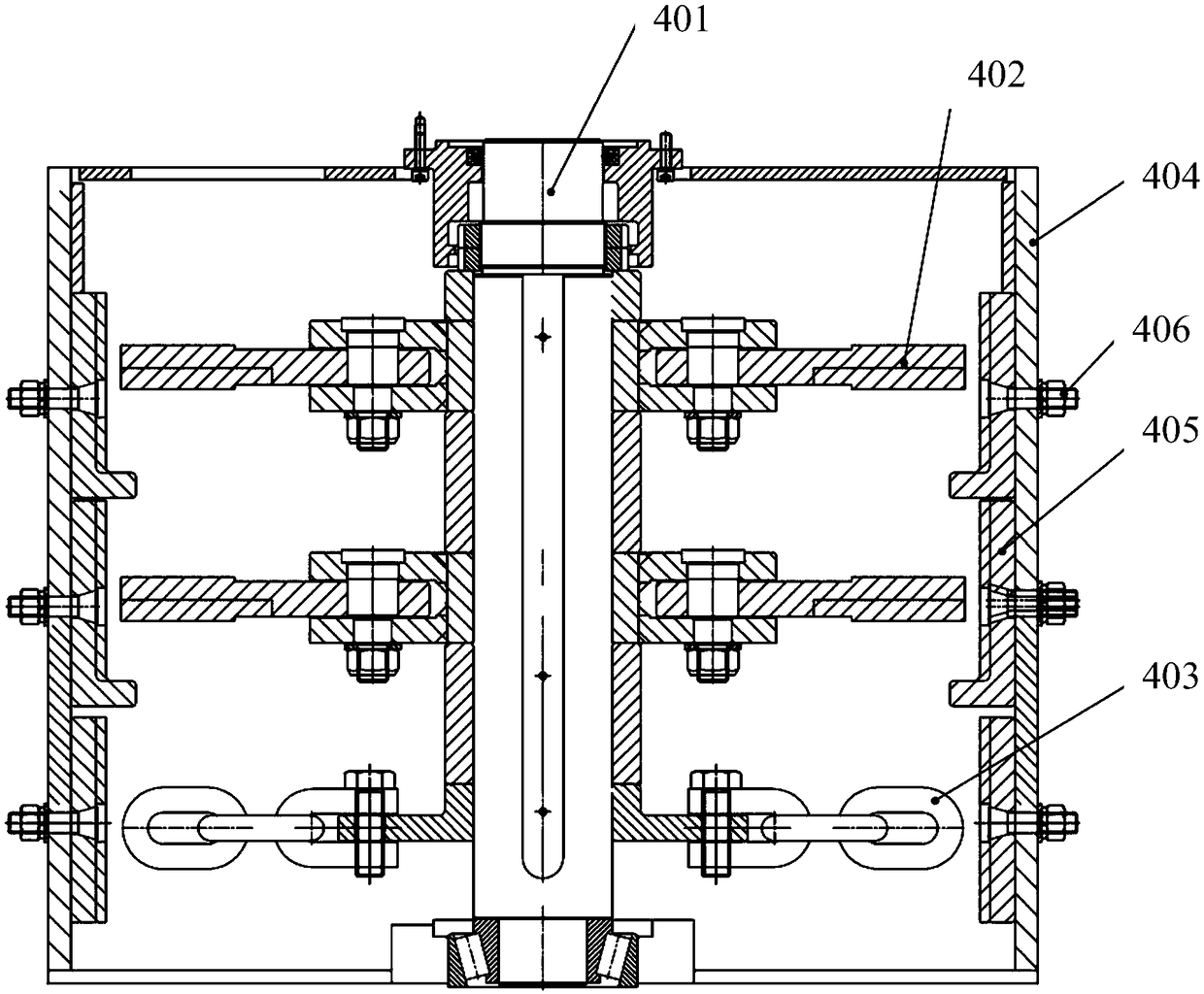

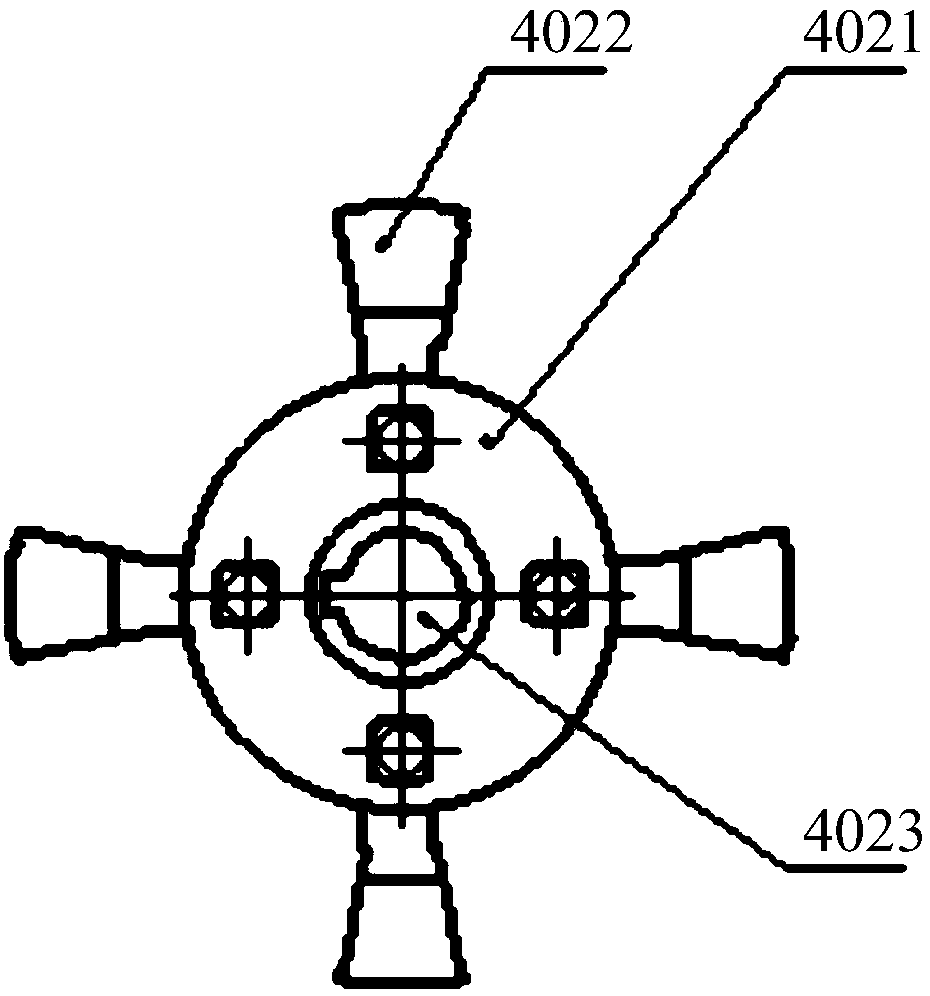

[0056] Such as figure 2 As shown, the primary vertical crusher 4 is provided with a first central shaft 401, and the two ends of the first central rotary shaft 401 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com