Passive damping boring rod with adjustable frequency and adjusting method thereof

A passive and dynamic vibration reduction technology, applied in the direction of the boring bar, can solve the problems of small frequency adjustment range and great influence on the rigidity of the boring bar, so as to achieve the effect of improving stiffness and structural damping, improving vibration damping ability, and saving internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

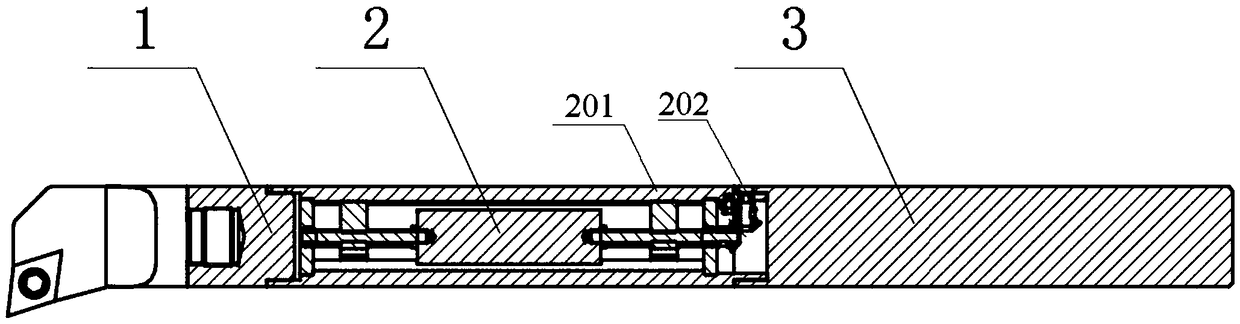

[0034] Such as figure 1 As shown, it includes the cutter head connection block 1, the boring bar damping section 2 and the boring bar clamping section 3, wherein the cutter head connecting block 1, the boring bar vibration damping section 2 and the boring bar clamping section 3 are connected by threads in sequence, and the whole The damping boring tool is designed in segments, which can be combined according to actual needs to obtain the required length of the boring bar.

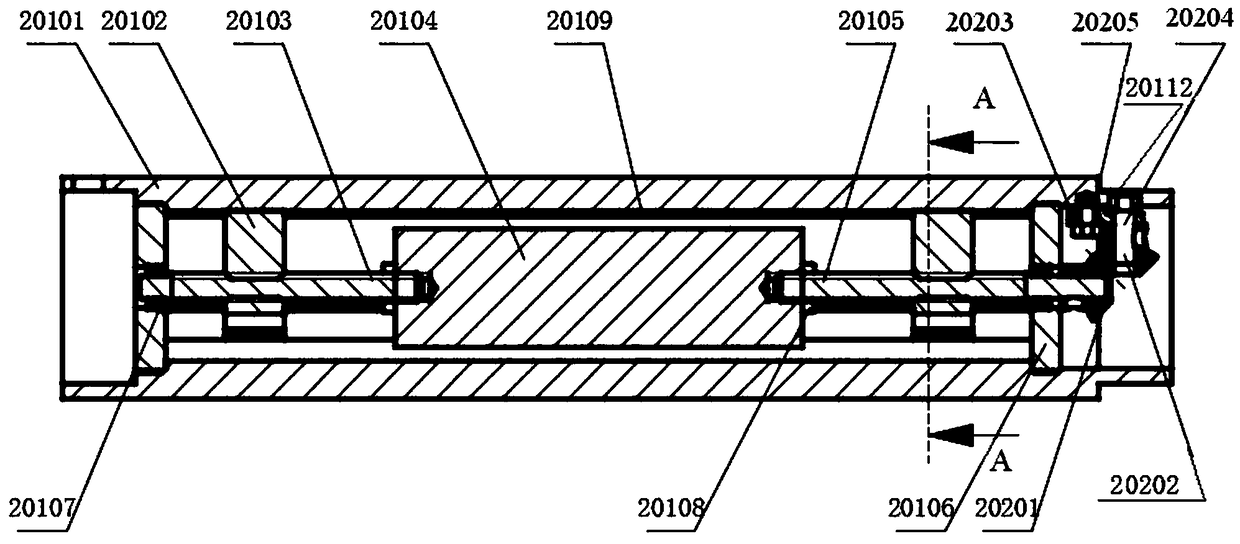

[0035] Such as figure 2 , 3 As shown, the damping section 2 of the boring bar includes a damping structure 201 and an adjusting gear set 202;

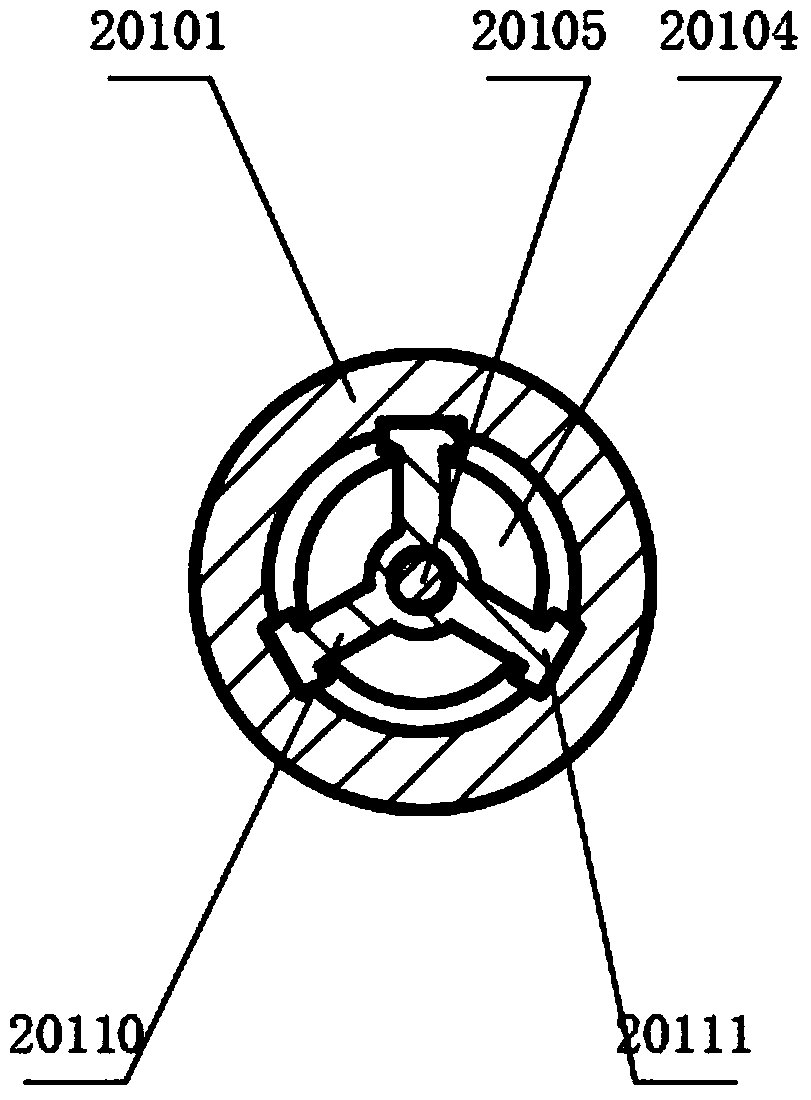

[0036] The damping structure 201 is arranged inside the cavity of the damping section 2 of the boring bar, including the shell 20101 of the damping section of the boring bar, the sliding support block 20102, the left-handed elastic damping rod 20103, the dynamic damping block 20104, and the right-handed elastic damping rod 20105, circular support 20106, miniatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com