Floss fusing device for floss machine

A technology of dental floss machine and dental floss stick, which is applied in the direction of metal processing, etc., can solve the problems of poor quality, black thread, yellowing of plastic, etc., and achieve the effect of perfect surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

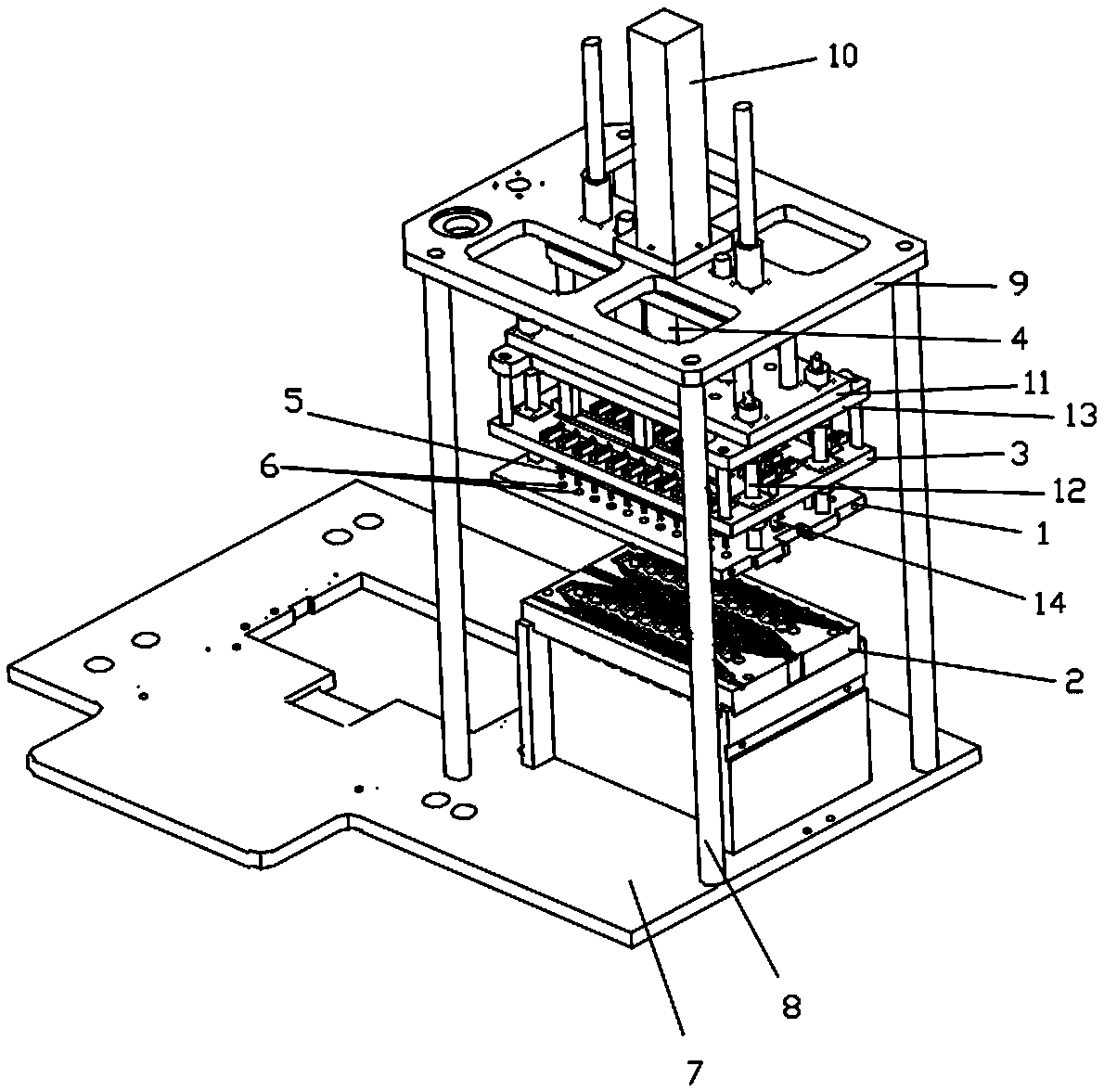

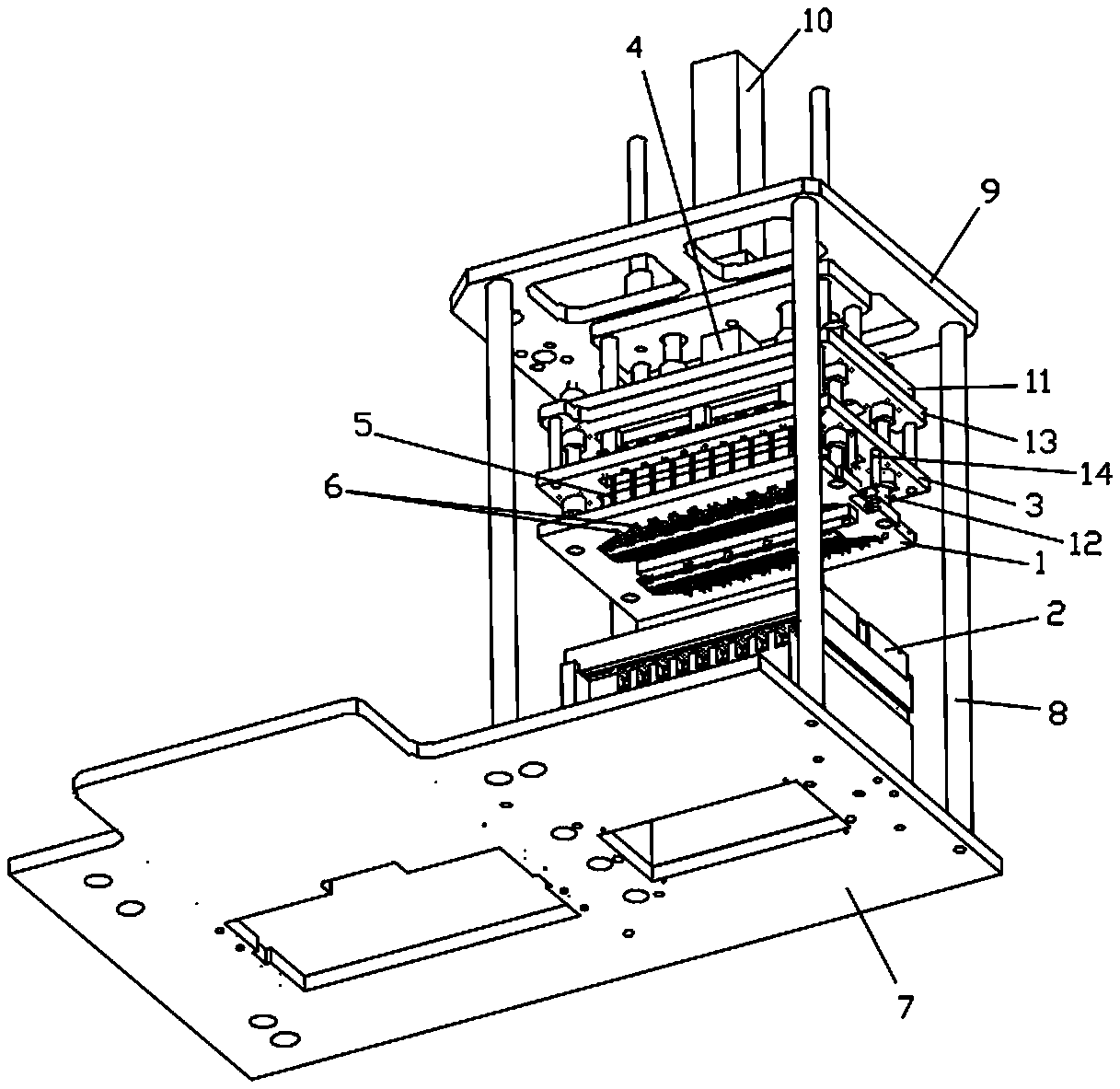

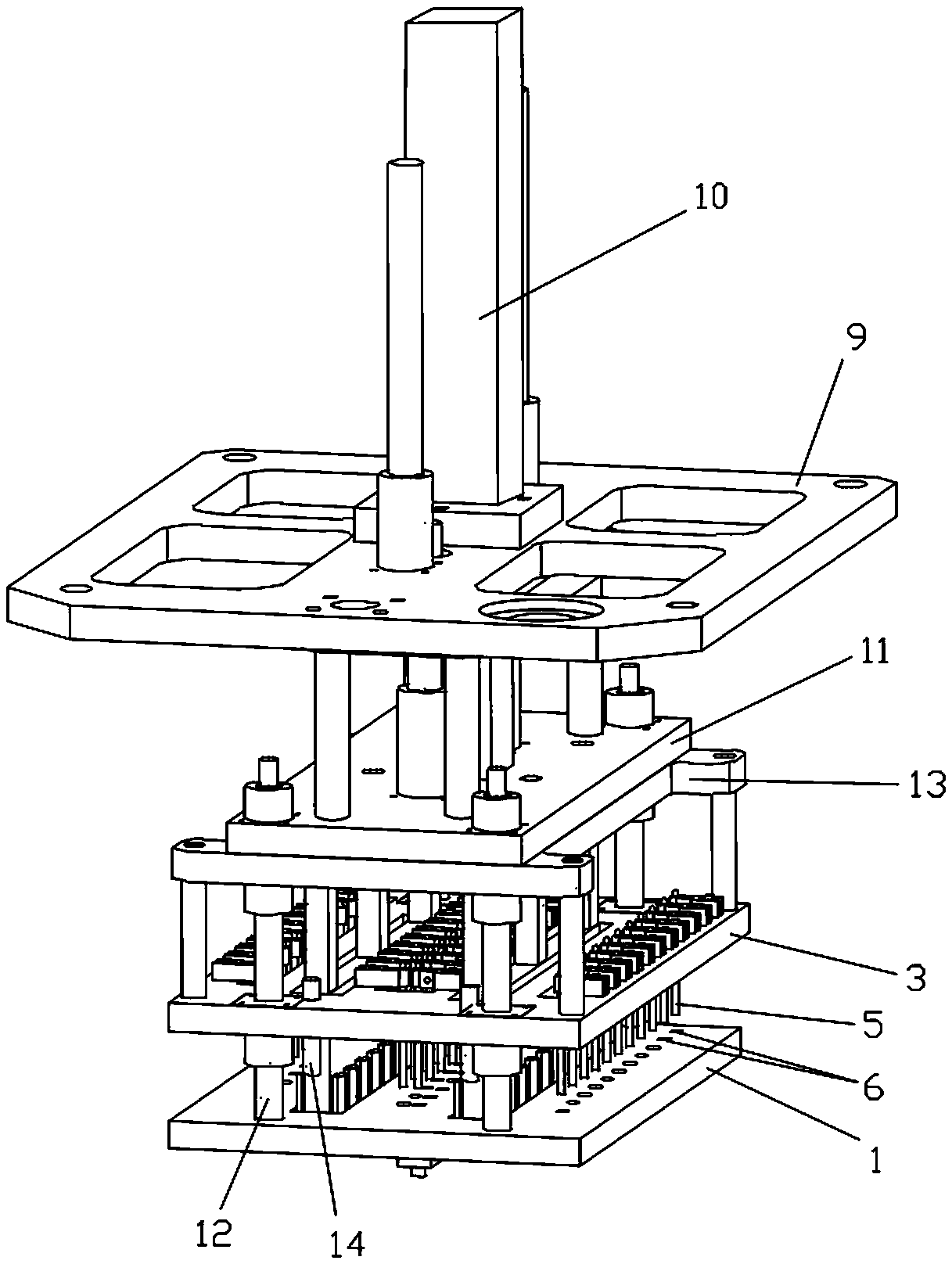

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Such as Figure 1 to Figure 4 As shown, the present invention provides a flossing device for a dental floss machine, comprising a dental floss stick upper mold 1 and a dental floss stick lower mold 2, a heating rod connecting plate 3 is arranged above the dental floss stick upper mold 1, and the The top of the heating rod connecting plate 3 is provided with a cylinder 4 that drives the heating rod connecting plate 3 to move up and down. The heating rod connecting plate 3 is connected with a hollow heating rod 5, and the top of the hollow heating rod 5 is connected to an external air source. The upper die 1 of the wire rod and the lower die 2 of the dental floss rod are provided with a transparent channel 6 for inserting the bottom of the hollow heating rod 5 corresponding to the hollow heating rod 5. above the fusing part of the thread.

[0020] Pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com