a fe 3 o 4 Preparation method of quasi-cubic particle/multilayer graphene composite material

A technology of multi-layer graphene and composite materials, which is applied in the field of materials, can solve the problems of uniform composite materials and inaccessibility, and achieve the effect of simple preparation, low price, and strong metal ion loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] see Figure 4 , shown as a Fe of the present invention 3 o 4 The flow chart of the preparation method of quasi-cubic particle / multilayer graphene composite material comprises the following steps:

[0028] S10: Measure DMF and distilled water with a volume ratio of 8:2, mix them as a mixed solvent, and the sum of their volumes is used for calculation as the volume of the mixed solution;

[0029] S20: add expanded graphite, and ultrasonically vibrate for 3 hours to obtain a mixed solution of multilayer graphene;

[0030] S30: Add urea and anhydrous sodium acetate into the multilayer graphene mixed solution, and stir magnetically for 5-10 minutes. The added amount of urea is 2-5 mg / mL, and the added amount of anhydrous sodium acetate is 10 mg / mL.

[0031] S40: Add iron powder and dilute nitric acid to the above solution. The amount of iron powder to be added is 3-5 mg / mL, dilute nitric acid is formulated to 2 mol / L before adding, and the added volume is 1 / 10-1 / 5 of th...

example 1

[0036] Mix 8 mL of DMF and 2 mL of distilled water as a mixed solvent, add 15 mg of expanded graphite, and obtain the required multilayer graphene solution after ultrasonic oscillation for 3 hours, add 100 mg of anhydrous sodium acetate and 20 mg of urea to the mixed solution, stir magnetically for 10 minutes, and then Add 40mg of iron powder and 2mL of dilute nitric acid to make 2mol / L. Then it was stirred for 8 hours in a water bath at 80° C. at a speed of 320 / min. The reactants were taken out and centrifuged three times with alcohol and distilled water respectively, and finally dried at 60°C in a drying oven for 24 hours to obtain Fe 3 o 4 Quasi-cubic particle / multilayer graphene composites.

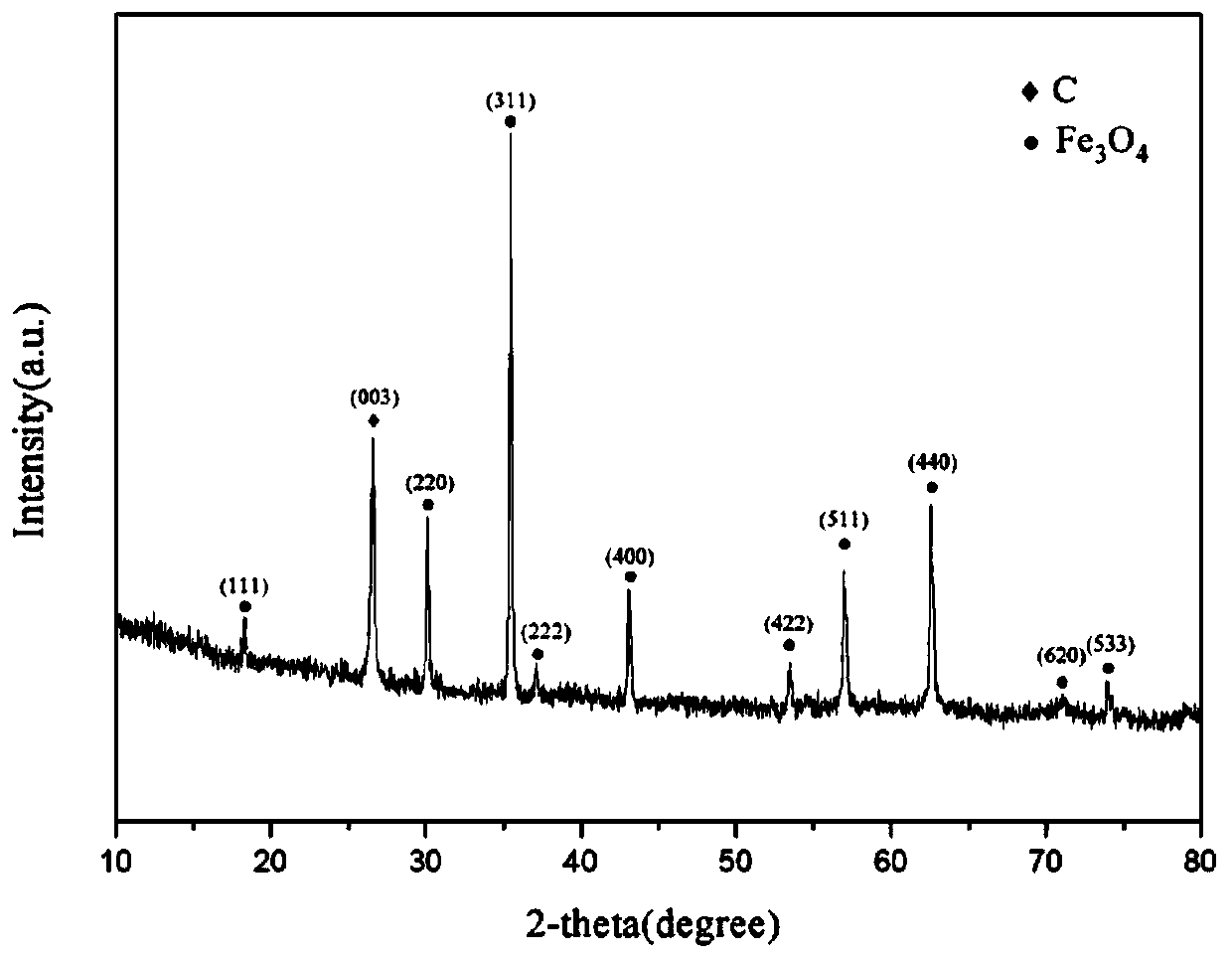

[0037] figure 1 Be the x-ray diffraction diffractometer (XRD) collection of illustrative plates of the sample that this method obtains, can see the diffraction peak of multilayer graphene and Fe from the figure 3 o 4 diffraction peaks.

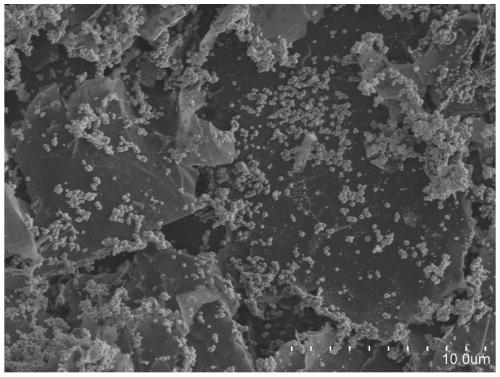

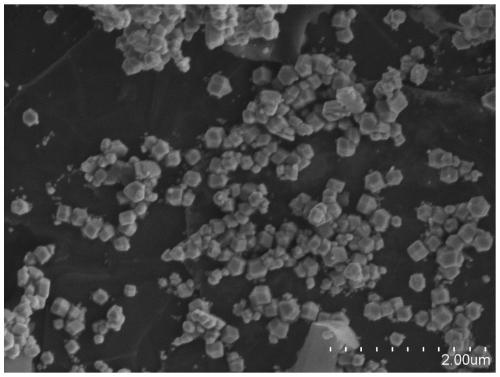

[0038] figure 2 and image 3 is a scan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com