A kind of high-resistivity high-entropy alloy thin film and its preparation method

A high-entropy alloy and high-resistivity technology, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems that the low resistivity cannot meet the practical application, and achieve fast and convenient adjustment, improve efficiency, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

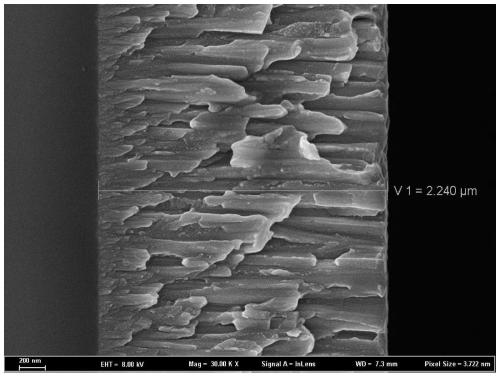

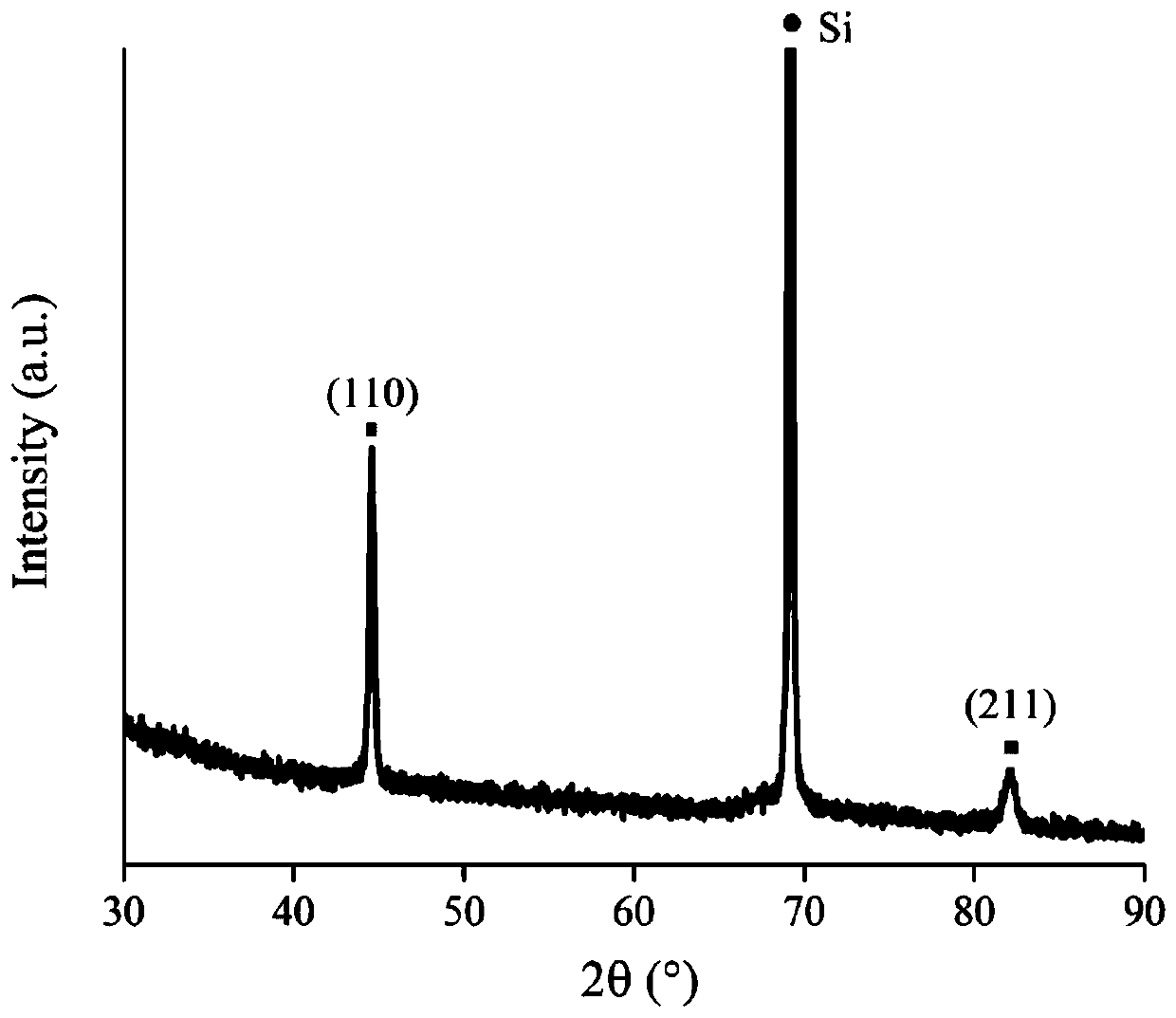

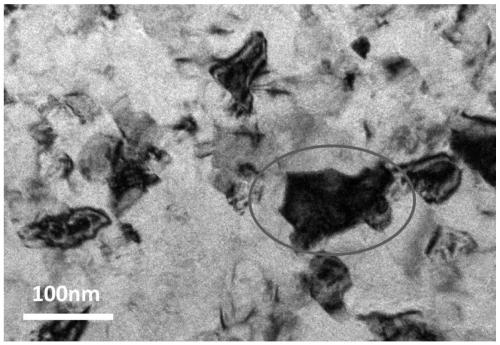

[0031] A high-resistance high-entropy alloy film, the film contains six elements of iron, cobalt, nickel, aluminum, manganese, and tungsten, and the atomic percentage of the elements is 33:30:16:7:9:5.

[0032] A method for preparing a high-resistance high-entropy alloy thin film, the specific process method is as follows

[0033] 1) The monocrystalline silicon substrate polished on one side was placed in acetone, deionized water and alcohol for 15 minutes in sequence, ultrasonically cleaned for 15 minutes, dried and placed on the sample stage of the radio frequency magnetron sputtering vacuum chamber.

[0034] 2) Prepare corresponding proportions of pure metal fan-shaped targets according to the ratio of the required components. The apex angles of the six element fan-shaped targets of iron, cobalt, nickel, aluminum, manganese, and tungsten are 118.8°, 108°, 57.6°, 25.2°, 32.4°, 18°, assemble it into a complete circular composite target with a diameter of 60mm, and place it on...

Embodiment 2

[0042] A high-resistance high-entropy alloy film, the film contains six elements of iron, cobalt, nickel, aluminum, manganese, and tungsten, and the molar ratio of the elements is 30:30:16:8:10:6.

[0043] A method for preparing a high-resistance high-entropy alloy thin film, the specific process method is as follows

[0044] 1) The monocrystalline silicon substrate polished on one side was placed in acetone, deionized water and alcohol for 15 minutes in sequence, ultrasonically cleaned for 15 minutes, dried and placed on the sample stage of the radio frequency magnetron sputtering vacuum chamber.

[0045] 2) According to the proportion of the required components, prepare the corresponding proportion of pure metal fan-shaped targets. The apex angles of the six element fan-shaped targets of iron, cobalt, nickel, aluminum, manganese, and tungsten are 108°, 108°, 57.6°, 28.8°, 36°, 21.6°, put them together into a complete circular composite target with a diameter of 60mm, and pla...

Embodiment 3

[0052] A high-resistance high-entropy alloy film, the film contains six elements of iron, cobalt, nickel, aluminum, manganese, and tungsten, and the molar ratio of the elements is 33:30:16:7:9:5.

[0053] A method for preparing a high-resistance high-entropy alloy thin film, the specific process method is as follows

[0054] 1) The monocrystalline silicon substrate polished on one side was placed in acetone, deionized water and alcohol for 15 minutes in sequence, ultrasonically cleaned for 15 minutes, dried and placed on the sample stage of the radio frequency magnetron sputtering vacuum chamber.

[0055] 2) Prepare corresponding proportions of pure metal fan-shaped targets according to the ratio of the required components. The apex angles of the six element fan-shaped targets of iron, cobalt, nickel, aluminum, manganese, and tungsten are 118.8°, 108°, 57.6°, 25.2°, 32.4°, 18°, assemble it into a complete circular composite target with a diameter of 60mm, and place it on the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com