Intermetallic compound-aerogel composite material, and preparation method and application thereof

A technology of intermetallic compounds and composite materials, which is applied in the composite materials of intermetallic compounds and aerogels and their preparation and application fields, can solve the problems of limiting the application of photothermal materials, low material temperature, and reduced efficiency, and achieve source distribution Wide, high temperature, low heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

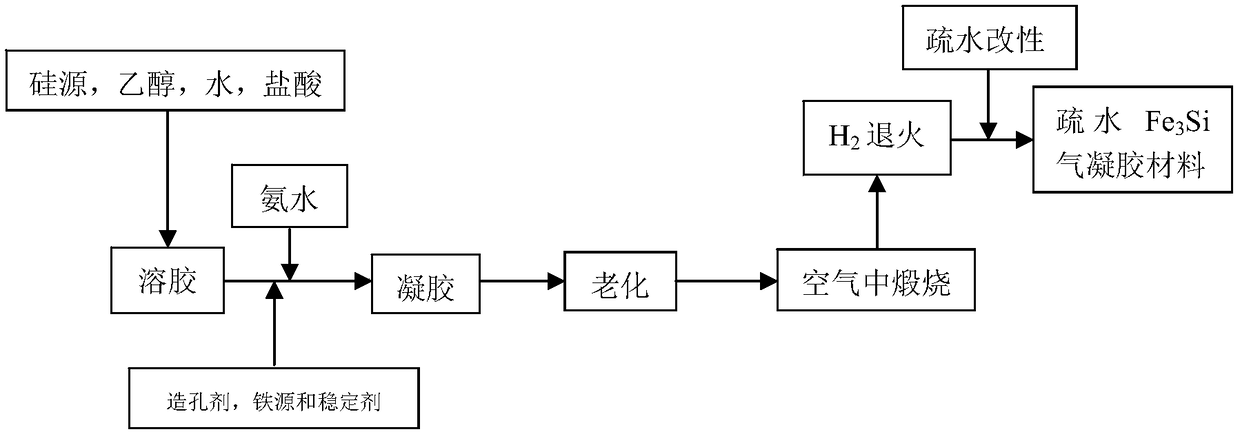

[0040] Fe 3 Si intermetallic compound SiO 2 Airgel composites:

[0041] (1) Dissolve 10ml of tetraethyl orthosilicate in ethanol, add 300ul of hydrochloric acid and 600ul of deionized water, and stir at 85°C for 4 hours to obtain a silica sol; add 10g of PEG2000 and 3g of Ferric nitrate, after the above medicines are all dissolved, add triethanolamine with an amount six times that of iron, then quickly add 5ml of ammonia water to the above mixed solution, the sol will gel rapidly, and obtain iron hydroxide and silicon dioxide. Gel; the gel is sealed and aged at a constant temperature of 65°C for several days, then taken out and dried and calcined in a horse boiling furnace for 6 hours under the condition that the temperature rises from 5°C to 500°C per minute to obtain iron-doped silica gas Gel material; then annealed at 400°C under a hydrogen environment to obtain an iron-silicon intermetallic compound silica airgel composite material. Soak the composite material with a 10...

Embodiment 2

[0048] Fe 2 Si intermetallic compound SiO 2 Airgel composites:

[0049] (1) Dissolve 8ml of methyl orthosilicate in ethanol, add 300ul of hydrochloric acid and 600ul of deionized water, and stir at 85°C for 4 hours to obtain a silica sol; add 0.05g of polyethylene to the above sol Alcohol and 1.5g ferric chloride, after the above medicines are all dissolved, add the diethanolamine of ten times the amount of iron material, then quickly add 5ml ammonia water to the above mixed solution, the sol will gel rapidly, and obtain iron-doped di Silica gel; seal the gel and age it in a constant temperature environment of 70°C for several days, then take it out and dry it and calcinate it in a horse boiling furnace for 6h, the condition is that the temperature rises from 5°C to 500°C per minute to obtain iron-doped dioxide Airgel material of silicon; then annealed at 500°C under hydrogen environment to obtain iron-silicon intermetallic compound silicon dioxide airgel photothermal materi...

Embodiment 3

[0053] FeSi 2 intermetallic compound SiO 2 Airgel composites:

[0054] (1) Dissolve 10ml of methyl orthosilicate in ethanol, add 300ul of hydrochloric acid and 600ul of deionized water, and stir at 85°C for 4 hours to obtain a silica sol; add 1g of ferric acetate and 3 Gram carbon particles and ultrasonically disperse them with a cell pulverizer. After the drug is dissolved, add ethanolamine in an amount four times that of iron, and then quickly add 5ml of ammonia water to the above mixed solution, and the sol will quickly gel. Seal the gel and age it at a constant temperature of 65°C for a few days, then take it out and dry it and calcinate it in a horse boiling furnace for 6 hours under the condition that the temperature rises from 5°C to 600°C per minute to obtain an iron-doped silica airgel material; Then annealing at 550° C. under a hydrogen environment to obtain an iron-silicon intermetallic compound silicon dioxide airgel photothermal material. The material was soake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com