Nucleic acid synthesis solid phase carrier, preparation method, nucleic acid synthesis device containing the carrier, and nucleic acid synthesis method

A solid-phase carrier and nucleic acid technology, applied in biochemical equipment and methods, DNA preparation, biochemical cleaning equipment, etc., can solve the problems of inconvenient synthesis operation, reduce the amount of reagents, facilitate the synthesis method, and avoid plastic pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

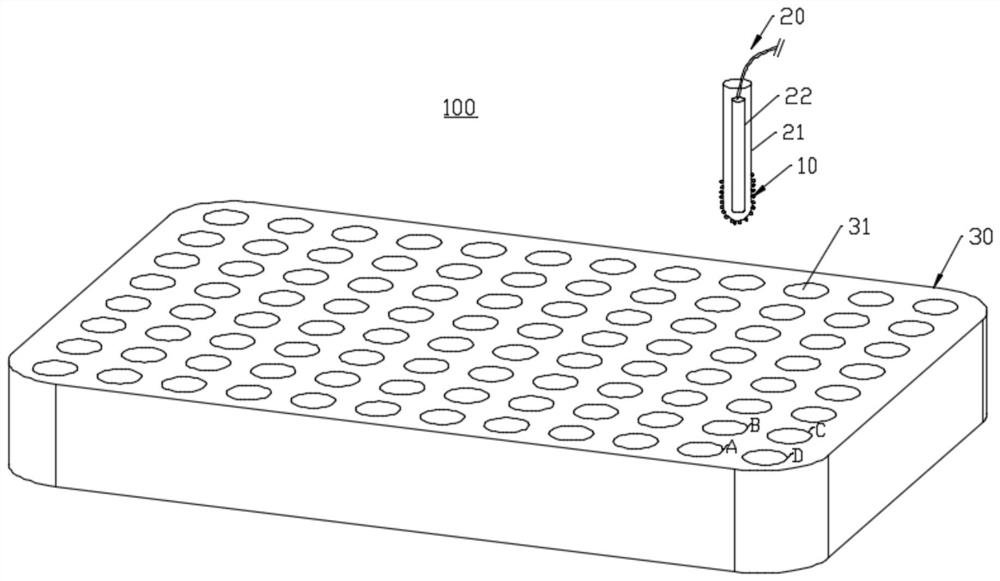

[0035] The embodiment of the present invention provides a method for preparing a nucleic acid synthesis solid phase carrier, comprising the following steps:

[0036] S1, obtaining water-based magnetic fluid. Preferably, the step of obtaining water-based magnetic fluid comprises:

[0037] S11, dissolving ferric chloride hexahydrate and ferric chloride tetrahydrate in a molar ratio of 1 to 3:1 in water to obtain Fe 3+ Iron salt solution with a concentration of 0.2-0.5mol / L. Further, the molar ratio of ferric chloride hexahydrate to ferric dichloride tetrahydrate is 2:1, and the concentration of the iron salt solution is 0.3 mol / L.

[0038] S12, under an inert atmosphere, add a precipitating agent, stir in a water bath at 70-90° C. for 20-40 min, and separate to obtain a precipitated product. Further, nitrogen or helium is selected as the inert gas. Ammonia water is selected as the precipitating agent.

[0039] Further, in a preferred embodiment of the present invention, in ...

Embodiment 1

[0072] A kind of MCPG provided by the present embodiment is prepared according to the following steps:

[0073] (1) Dissolve ferric trichloride hexahydrate and ferric trichloride tetrahydrate in water at a molar ratio of 2:1 and add them to a three-necked flask so that the concentration of iron ions in the solution is 0.3mol / L. Under the protection of nitrogen, add excess ammonia water to form a black precipitate. At the same time, stir vigorously, heat in a constant temperature water bath at 80°C, and maintain PH = 10-11, and stop stirring after 30 minutes. Suction filtration, washing with deionized water until the filtrate flowing down is neutral, and the precipitated product is obtained.

[0074] (2) Disperse the obtained precipitated product in 50ml of water, add 1ml of tartaric acid, heat and stir in a constant temperature water bath at 70°C, and prepare a water-based magnetic fluid after 30min.

[0075] (3) 100mgFe 3 o 4 The fine particles are dispersed in a system of...

Embodiment 2

[0081] A nucleic acid synthesis method provided in this embodiment comprises the following steps:

[0082] (1) Take by weighing 0.5mgMCPG (provided in embodiment 1), insert the electromagnetic rod (hereinafter referred to as reaction rod) of adsorption MCPG in the dichloromethane solution of 1% trifluoroacetic acid, power on and off 30 times, make MCPG in the reaction solution Repeatedly disperse, aggregate, and react to remove the 5' hydroxyl protecting group DMT.

[0083] (2) Mix the required nucleotide monomers and tetrazolium to obtain an activated nucleoside phosphorous acid intermediate, insert the reaction rod and turn it on and off 50 times.

[0084] (3) Insert the reaction rod into the mixed solution of acetic anhydride and acetonitrile and turn it on and off 50 times;

[0085] (4) Insert the reaction rod into the mixture of iodine, pyridine and water and turn it on and off 50 times

[0086] (5) Steps (1)-(4) are repeated until the desired nucleic acid sequence is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com