A method for constructing superhydrophobic wear-resistant leather coating based on amphiphilic hollow silica janus particles

A silicon dioxide, amphiphilic technology, applied in the direction of silicon dioxide, silicon oxide, coating, etc., can solve the problem that the coating has not achieved super-hydrophobic effect, the wear resistance and hydrophobic durability of the coating have not been solved, etc. problem, to achieve the effect of regular morphology and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the present invention comprises the following steps:

[0031] (1) Amphiphilic hollow SiO 2 Preparation of Janus particles

[0032]Weigh 0.50-2.00g of azobisisobutylamidine hydrochloride, 100-300g of deionized water and 0.25-0.50g of hexadecyltrimethylammonium bromide, dissolve and stir evenly, then transfer to a three-necked flask. Then, 3.00-5.00 g of styrene was added under stirring, and argon gas was introduced for 1 h, and then the temperature was raised to 60-80° C. for 10-24 h, and the polystyrene (PS) emulsion was obtained. Measure 15-35mL of PS emulsion, 10-40mL of deionized water and 40-160mL of isopropanol, stir well, transfer to a three-necked flask, and adjust the pH to 8-11 with ammonia water. Then, add 0.5-5.0g of tetraethyl orthosilicate dropwise into the three-necked flask, raise the temperature to 30-85°C after the dropwise addition, keep the temperature for 3-8h, wash by centrifugation three times, and dry in an oven to obta...

Embodiment 1

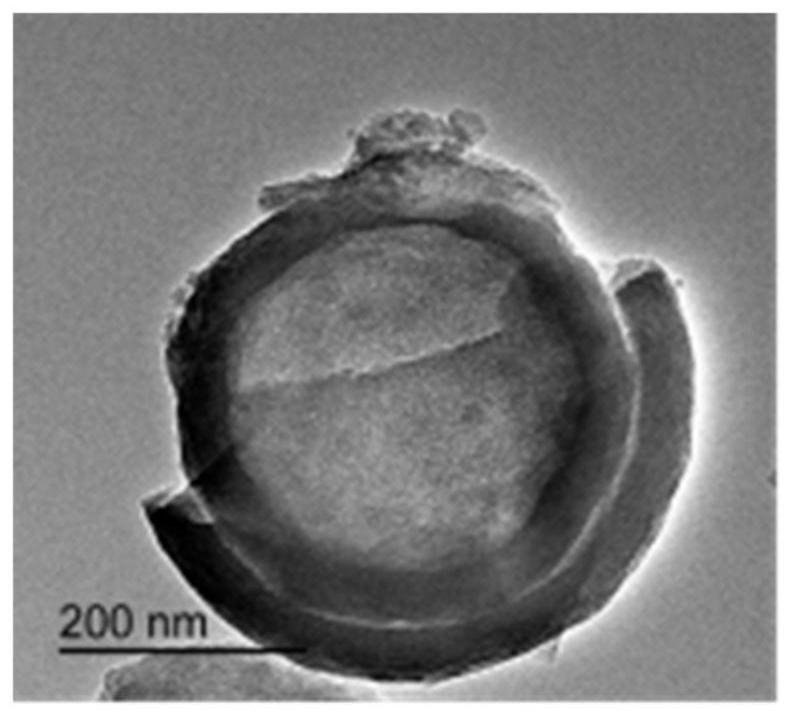

[0040] (1) Hollow SiO 2 Particle preparation

[0041] Weigh 0.50 g of azobisisobutylamidine hydrochloride, 100 g of deionized water, and 0.25 g of cetyltrimethylammonium bromide, dissolve and stir evenly, and transfer them to a three-necked flask. Then, 3.00 g of styrene was added under stirring, and argon gas was introduced for 1 h, and then the temperature was raised to 60° C., and the reaction was kept for 10 h to obtain a polystyrene (PS) emulsion. Measure 15mL of PS emulsion, 10mL of deionized water and 40mL of isopropanol, stir evenly, transfer to a three-necked flask, and adjust the pH to 8 with ammonia water. Then, 0.5 g of tetraethyl orthosilicate was added dropwise to the three-necked flask, and after the dropwise addition, the temperature was raised to 30°C, kept for 3 hours, centrifuged and washed three times, and dried in an oven to obtain PS@SiO 2 particle. Finally, calcined in a muffle furnace at 500 °C for 3 h to prepare hollow SiO with a particle size of 30...

Embodiment 2

[0049] (1) Hollow SiO 2 Particle preparation

[0050] Weigh 2.00g of azobisisobutylamidine hydrochloride, 300g of deionized water and 0.50g of cetyltrimethylammonium bromide, dissolve and stir evenly, and then transfer to a three-necked flask. Then, 5.00 g of styrene was added under stirring, and argon was introduced for 1 h, and then the temperature was raised to 80° C., and the reaction was kept for 24 h to obtain a polystyrene (PS) emulsion. Measure 35mL of PS emulsion, 40mL of deionized water and 160mL of isopropanol, stir evenly, transfer to a three-necked flask, and adjust the pH to 11 with ammonia water. Then, 5.0 g of tetraethyl orthosilicate was added dropwise to the three-necked flask, and after the dropwise addition, the temperature was raised to 85°C, kept for 8 hours, centrifuged and washed three times, and dried in an oven to obtain PS@SiO 2 particle. Finally, calcined in a muffle furnace at 500 °C for 6 h to prepare hollow SiO with a particle size of 500 nm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com