Vapor chamber and manufacturing method thereof

A manufacturing method and sheet technology, applied in electrical components, polyether adhesives, circuit thermal devices, etc., can solve the problems of affecting device function, poor heat resistance, small thermal conductivity, etc. Chain density, the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

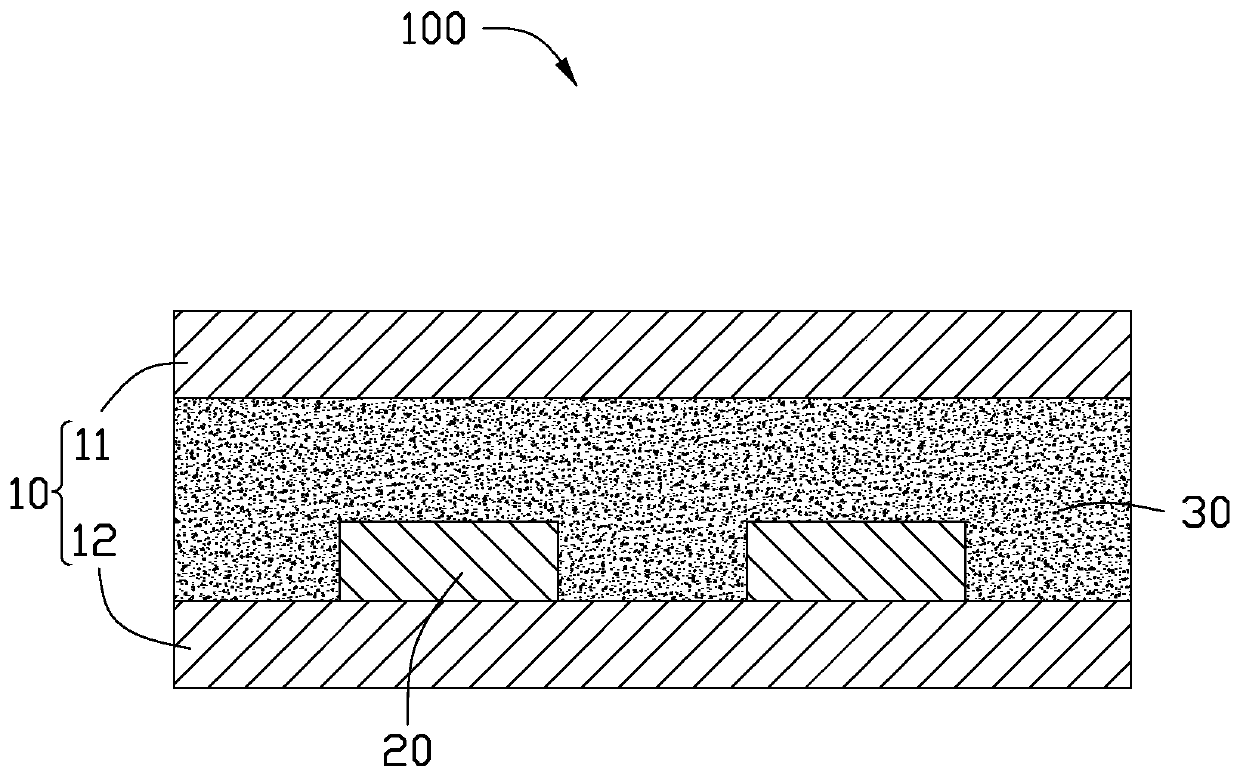

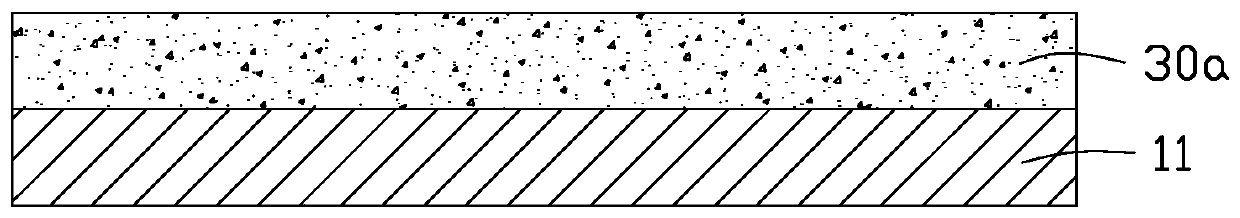

[0051] The adhesive layer 30 includes 35 parts by weight of styrene-butadiene-styrene block copolymer, 60 parts by weight of styrene-ethylene-butylene-styrene block copolymer, 10 parts by weight of polystyrene Phenyl ether, 40 parts by weight of dendritic acrylate oligomer, 7 parts by weight of heat conducting powder, 15 parts by weight of flame retardant and 3 parts by weight of ion scavenger. The thermal conductivity of the adhesive layer 30 in the first embodiment is 2.1 W / m.k.

Embodiment 2

[0053] The adhesive layer 30 includes 35 parts by weight of styrene-butadiene-styrene block copolymer, 60 parts by weight of styrene-ethylene-butylene-styrene block copolymer, 10 parts by weight of polyphenylene ether , 40 parts by weight of dendritic acrylate oligomer, 16 parts by weight of thermally conductive powder, 15 parts by weight of flame retardant and 3 parts by weight of ion scavenger. The thermal conductivity of the adhesive layer 30 in the first embodiment is 2.8 W / m.k.

Embodiment 3

[0055] The adhesive layer 30 includes 55 parts by weight of styrene-butadiene-styrene block copolymer, 40 parts by weight of styrene-ethylene-butylene-styrene block copolymer, 20 parts by weight of polyphenylene ether , 30 parts by weight of dendritic acrylate oligomer, 7 parts by weight of heat conducting powder, 15 parts by weight of flame retardant and 3 parts by weight of ion scavenger. The thermal conductivity of the adhesive layer 30 in the first embodiment is 1.9 W / m.k.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com