Environment-friendly asphalt concrete mixing equipment

An asphalt concrete, environmentally friendly technology, used in roads, road repair, roads, etc., can solve problems affecting construction quality, long process routes, uneven mixing, etc., to reduce the lifting of feeding equipment, shorten the process flow, and improve mixing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

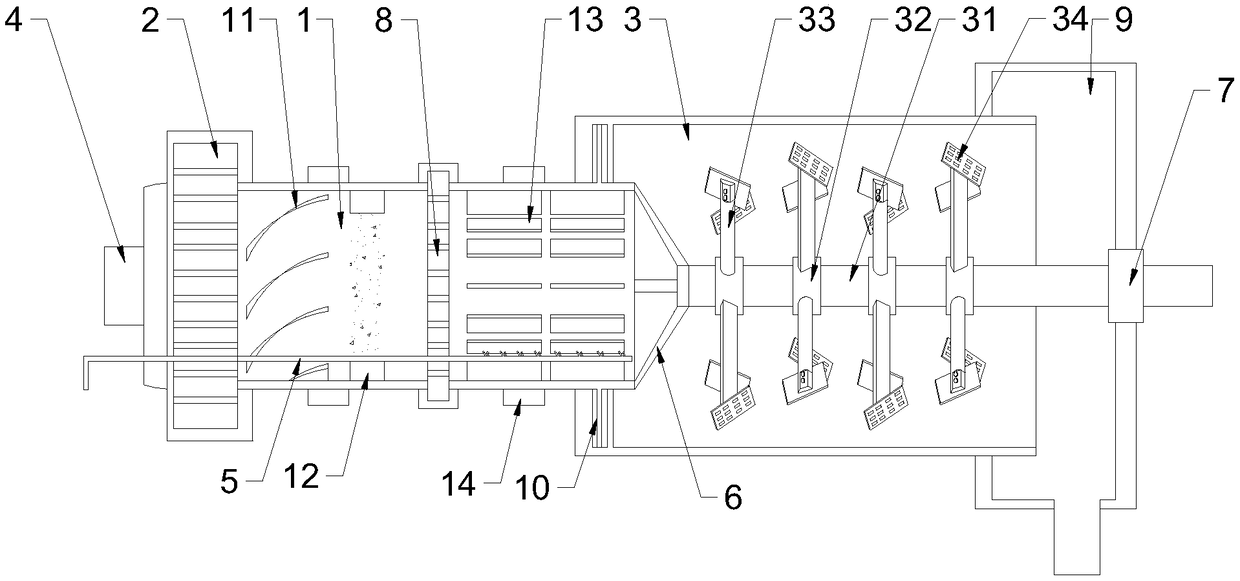

[0021] The present invention is described in further detail now in conjunction with accompanying drawing.

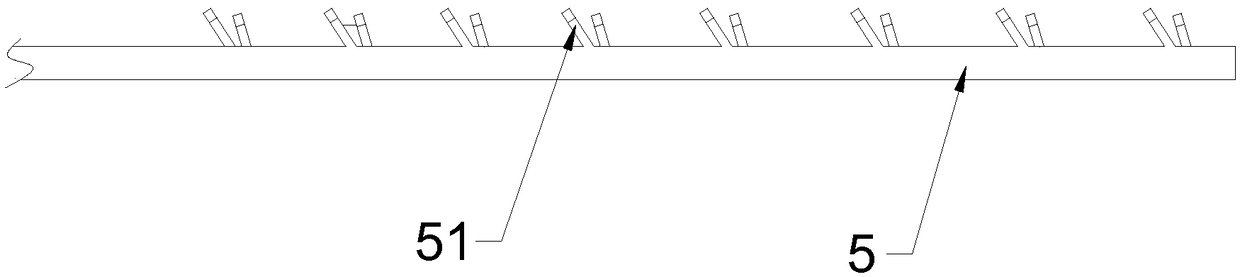

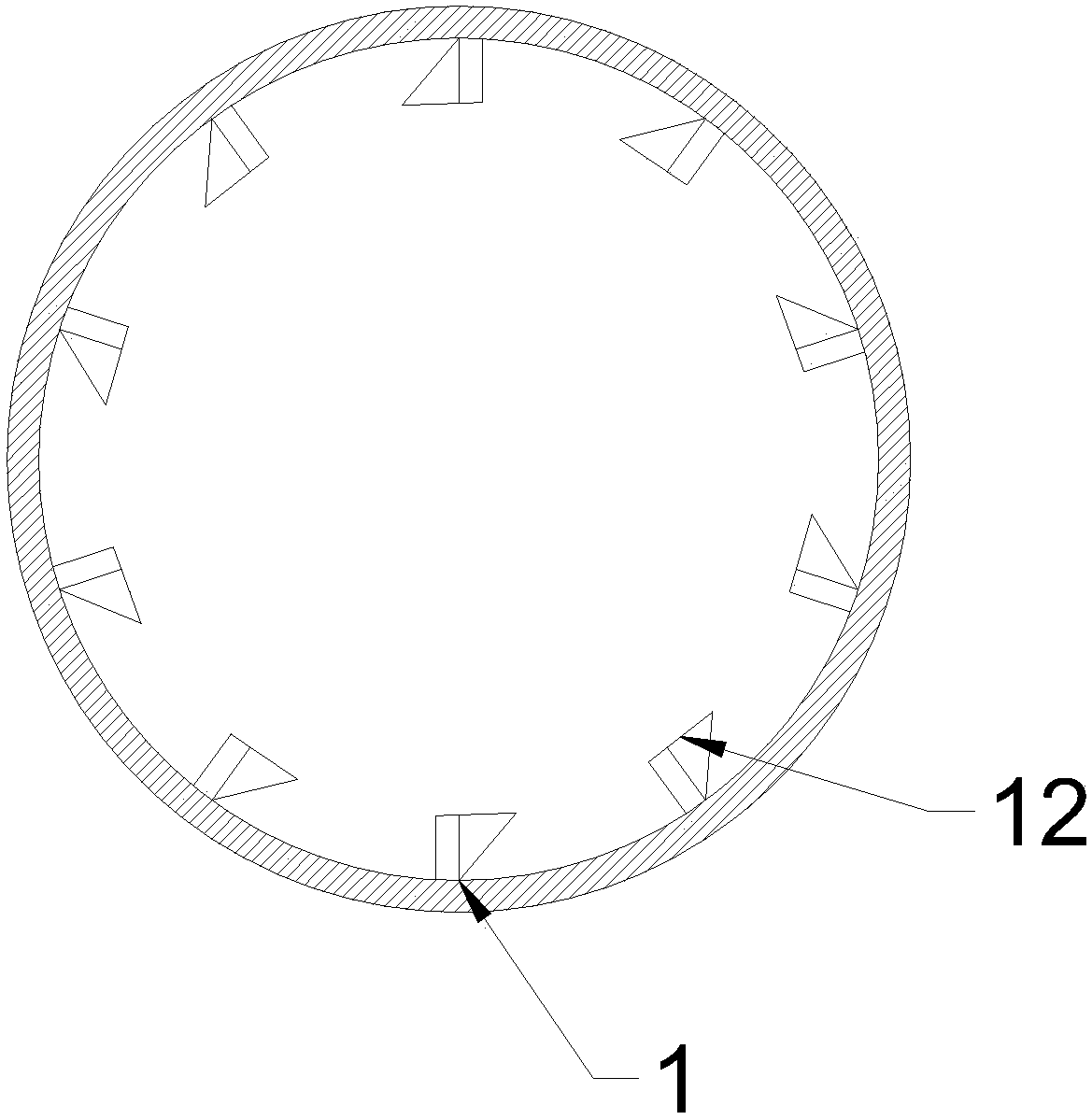

[0022] according to Figure 1 to Figure 3 The shown environment-friendly asphalt concrete mixing equipment includes a drying inner cylinder 1 and a mixing outer cylinder 2. Two sets of driving devices 14 are arranged on the outer wall of the drying inner cylinder 1. The front end of the drying inner cylinder 1 is installed There is a new material feeding box 2, and a burner 4 is installed at the end of the new material feeding box 2, and the inner surface of the drying inner cylinder 1 is sequentially provided with a cold mixing propulsion area, a material curtain forming area, a lifting sprinkler area, and In the landing area, the rear end of the inner drying cylinder 1 is assembled inside the front end of the outer mixing cylinder 3, and the inner drying cylinder 1 and the outer mixing cylinder 3 are connected by a rotatable sealing structure, and the inner drying cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com