Fabricated heat preservation decoration and structure integration wall and preparing and installing technology thereof

A prefabricated, wall technology, applied in the direction of thermal insulation, wall, building components, etc., can solve the problem of the inability to realize the simultaneous design, construction and acceptance of composite thermal insulation walls, the inability to achieve the same service life of building thermal insulation and prefabricated wall panels, It is difficult to overcome adverse effects and problems such as moisture resistance and condensation, and achieve the effects of large-scale production and popularization and application, enhanced seismic and wind resistance structural performance, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

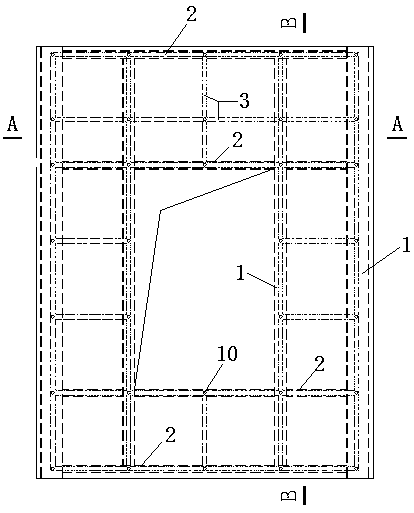

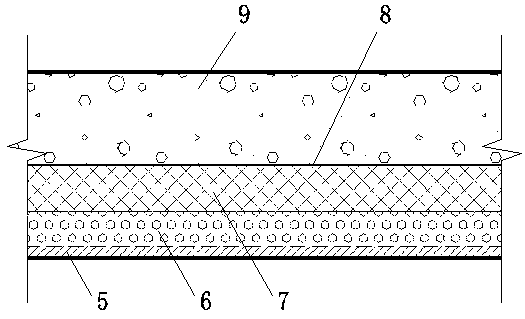

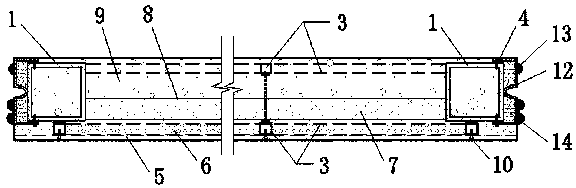

[0043] Such as figure 1 A prefabricated thermal insulation decoration and structural integrated wall body is shown, including a supporting frame, and a gradient composite thermal insulation layer poured and fixed with the support frame, and the gradual composite thermal insulation layer includes microcellular foam concrete arranged in sequence Base layer 9, waterproof and breathable layer 8, thermal insulation core material layer 7 and inorganic thermal insulation material gradual transition layer 6, the outer surface of the inorganic thermal insulation material gradual transition layer is provided with an outer decorative panel protective layer 5 fixedly connected to the supporting frame.

[0044] The support frame includes a column 1, a beam 2 and a support keel 3 fixedly connected together. The column 1 is a tubular stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com