Automotive adsorptive type oil filter

An oil filter and adsorption technology, which is applied in the installation/connection of lubricant purification devices, lubricating parts, pressure lubricants, etc., can solve the problem of poor adsorption of iron filings, failure to improve filter capacity, adsorption Problems such as limited range, to achieve self-cleaning, increase the range of contact, and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

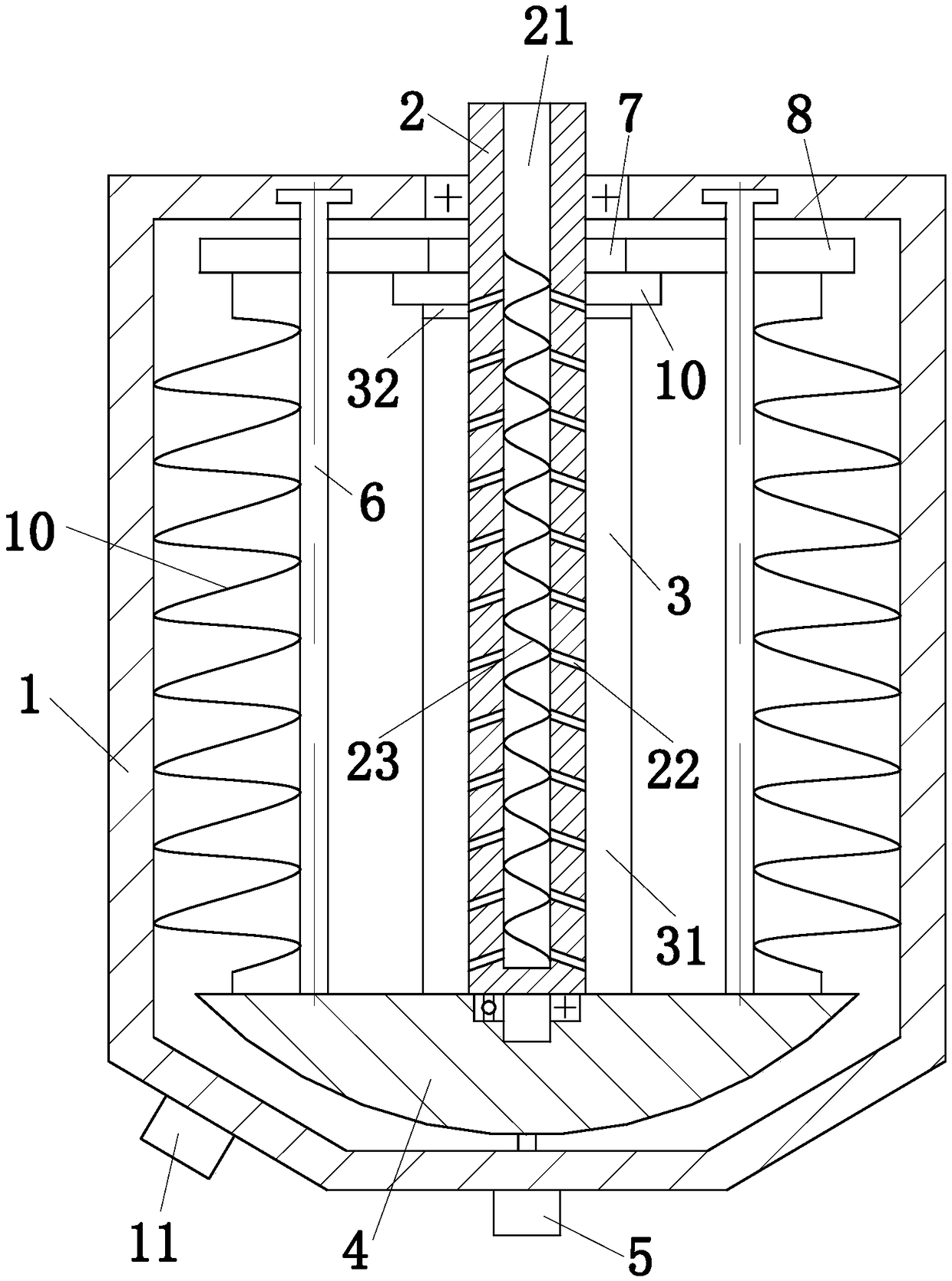

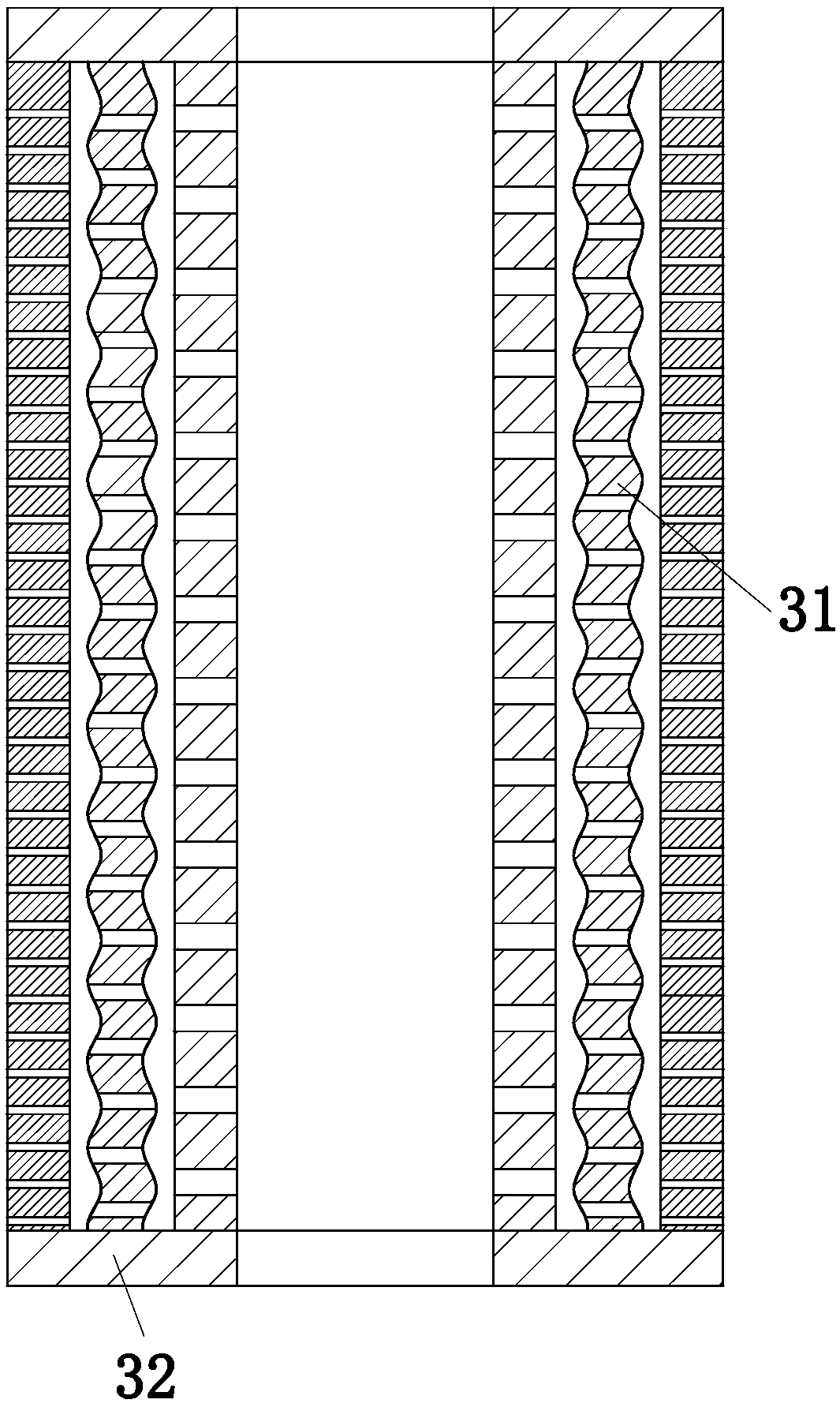

[0019] use figure 1 and figure 2 An automotive adsorption type oil filter according to an embodiment of the present invention will be described as follows.

[0020] Such as figure 1 As shown, a kind of automobile adsorption oil filter according to the present invention includes a housing 1, a conduit 2, a filter element 3, a base 4, a motor 5, a column 6, a gear 7 and a gear ring 8, and the housing 1 The bottom is provided with an oil drain 11, the top of the housing 1 is provided with a mounting hole, and the upper surface of the housing 1 is provided with an annular groove with a "T" shape in section; the conduit 2 extends vertically through the mounting hole of the housing 1 to the shell Inside the body 1, there is a rotational connection between the conduit 2 and the housing 1. The upper surface of the conduit 2 is vertically provided with an oil inlet channel 21 along the axial direction. The hole 22 communicates with the oil inlet passage 21 inside the conduit 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com