Method for lowering low-frequency noise of rear torsion beam automobile model braking

A low-frequency noise and torsion beam technology, applied in the field of automobile braking, can solve the problems of uneasiness of pedestrians and surrounding residents, affecting NVH performance, etc., and achieve good economic benefits, low cost, and increased manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Example 1: 1) A low-frequency noise evaluation test is carried out for a certain type of passenger car, and the temperature of the environment where the passenger car is located is controlled at -5°C to 0°C, the humidity is 95%rh to 100%rh, and the initial velocity is 0 to 100%. 5km / h, deceleration 0 ~ 0.1g, and test with the forward and backward combination of the whole vehicle respectively. The noise frequency under this working condition is obtained by the noise detector as 100Hz ~ 300HZ, which is within the frequency range of low frequency Moan noise, and Determine the above-mentioned operating conditions that produce the low-frequency Moan noise;

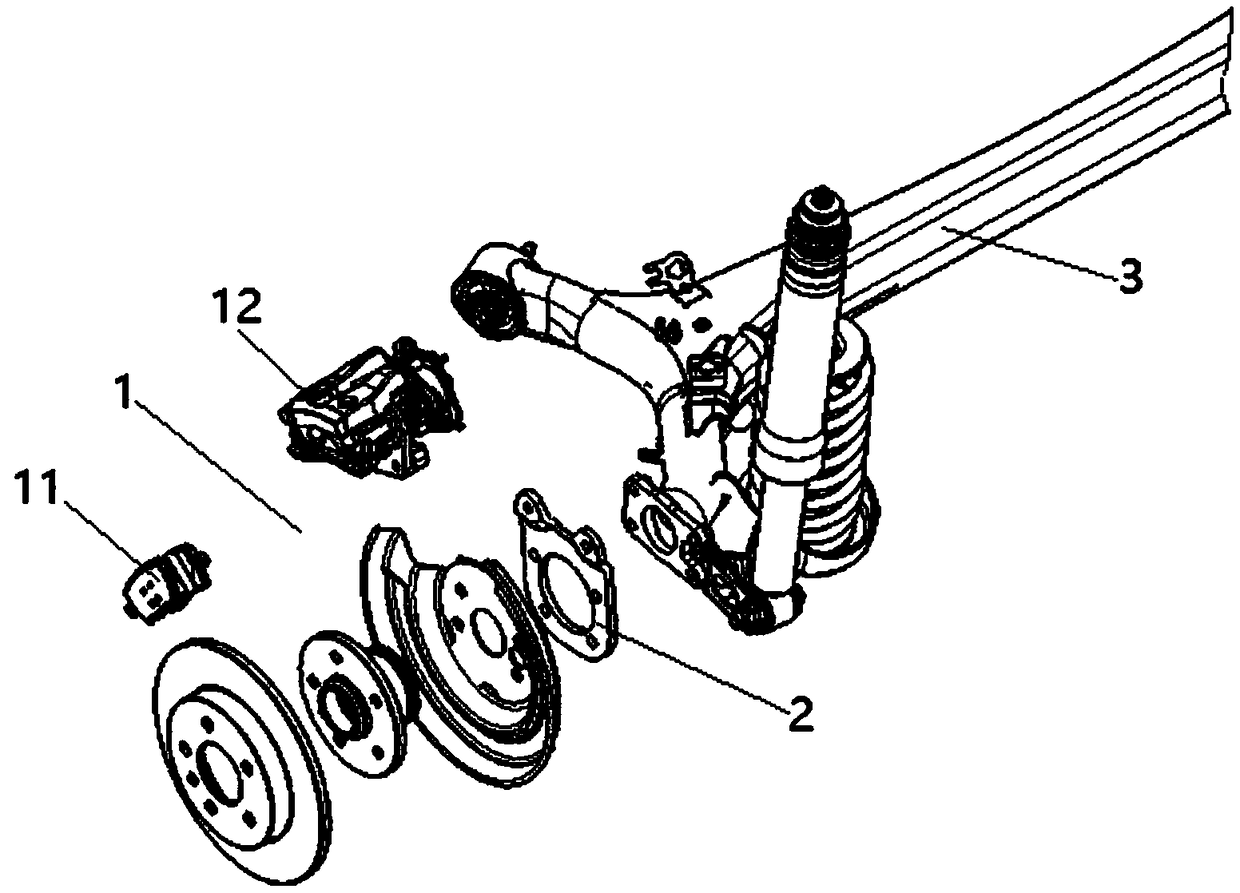

[0035] 2) Install the rear suspension system on the brake inertia bench test machine. The rear suspension system includes the rear disc brake 1, the torsion beam 3 and the hydraulic system that controls the movement of the rear disc brake 1. According to the working conditions that generate the above-mentioned low-frequenc...

Embodiment 2

[0038] Example 2: 1) The low-frequency noise evaluation test is carried out for the same passenger car, and the temperature of the environment where the passenger car is located is changed to 0°C-5°C, the humidity is 90%rh-95%rh, and the initial speed is 0-5km / h h. The deceleration is 0~0.1g, and it is tested with the combination of forward and backward of the whole vehicle respectively. The noise frequency under this working condition is obtained by the noise detector as 300Hz~800HZ, which is within the frequency range of low frequency noise, and it is confirmed that the noise is generated. The above working conditions of low frequency noise;

[0039] 2) Install the rear suspension system on the brake inertia bench test machine. According to the working conditions that generate the above-mentioned low-frequency noise, drive the brake disc to rotate on the inertia bench through the motor on it, and simulate the initial velocity and deceleration in the above range. Speed, simul...

Embodiment 3

[0042] Example 3: 1) The low-frequency noise evaluation test is carried out for the same passenger car, and the temperature of the environment where the passenger car is located is changed to 5°C-10°C, the humidity is 80%rh-90%rh, and the initial speed is 0-5km / h h. The deceleration is 0 ~ 0.1g, and the combination of forward and backward of the whole vehicle is tested respectively. The noise frequency under this working condition is obtained by the noise detector as 800Hz ~ 1000HZ, which is within the frequency range of low frequency noise. The above working conditions of low frequency noise;

[0043] 2) Install the rear suspension system on the brake inertia bench test machine. According to the working conditions that generate the above-mentioned low-frequency noise, drive the brake disc to rotate on the inertia bench through the motor on it, and simulate the initial velocity and deceleration in the above range. Speed, simulate and reproduce the low-frequency noise, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com