Preparation method of high-strength high-toughness beta-type titanium alloy metallographic specimen

A high-strength, high-toughness, metallographic sample technology, applied in the preparation of test samples, etc., can solve problems affecting metallographic observation, unfavorable scientific research and analysis, and affecting observation effects, etc., to achieve good feasibility and promotion prospects. Clear and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

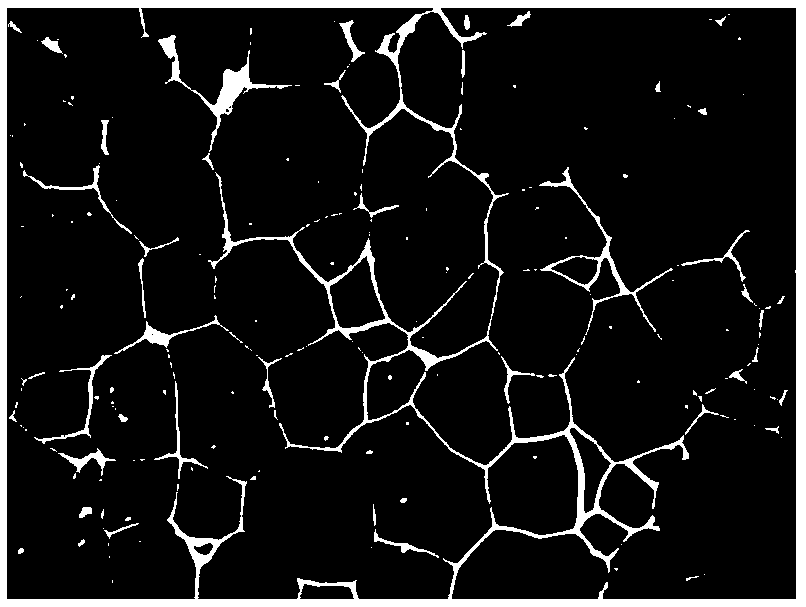

[0044] The invention provides a method for preparing a metallographic sample of a high-strength and high-toughness beta-type titanium alloy, comprising the following steps: a. taking a high-strength and high-toughness beta-type titanium alloy, grinding and polishing; b. putting the polished sample into water , heated to 50°C-100°C, and kept warm for 3min-5min; c. corroding the sample obtained in step b with a metallographic etchant solution, to obtain.

[0045] The present invention adds the operation (being step b) that the metallographic sample is heated between grinding and polishing and corrosion steps, mainly can bring following benefit: 1, can effectively shorten the required corrosion time of follow-up corrosion step; 2, Reduce the concentration of hydrofluoric acid required in the corrosive solution, thereby improving the safety of the corrosion operation of high-strength and high-toughness β-type titanium alloys; 3. Promote the corrosive effect of the corrosive solutio...

Embodiment 1

[0049] Embodiment 1 adopts the method of the present invention to prepare the metallographic sample of high-strength and high-toughness β-type titanium alloy

[0050] 1. Cut the high-strength and high-toughness β-type titanium alloy into a size of 10×10×10mm by wire cutting 3 The number of samples is 4, and a hot-mounting machine is used for hot-mounting metallographic sample preparation.

[0051]2. The surface of the hot-mounted sample to be observed is ground to a plane by a metallographic pre-grinding machine, and ground and polished on an automatic grinding and polishing machine. Use 180# water sandpaper and 1200# water sandpaper in turn for rough grinding, and add water to cool during the grinding process. Use a 9μm polishing disc and a 3μm polishing disc in turn for fine grinding, and clean the sample, polishing disc and sample disc with clean water every time the polishing disc is replaced. During the rough grinding and fine grinding process, the automatic grinding an...

Embodiment 2

[0056] Embodiment 2 adopts the method of the present invention to prepare the metallographic sample of high-strength and high-toughness β-type titanium alloy

[0057] 1. Cut the high-strength and high-toughness β-type titanium alloy into a size of 10×10×10mm by wire cutting 3 The number of samples is 4, and a hot-mounting machine is used for hot-mounting metallographic sample preparation.

[0058] 2. The surface of the hot-mounted sample to be observed is ground to a plane by a metallographic pre-grinding machine, and ground and polished on an automatic grinding and polishing machine. Use 180# water sandpaper and 1200# water sandpaper in turn for rough grinding, and add water to cool during the grinding process. Use a 9μm polishing disc and a 3μm polishing disc in turn for fine grinding, and clean the sample, polishing disc and sample disc with clean water every time the polishing disc is replaced. During the rough grinding and fine grinding process, the automatic grinding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com