A method and apparatus for uniform material counting based on machine vision

A counting method and machine vision technology, applied in the direction of counting, counting objects, counting mechanisms/items, etc. of items shipped through conveyors, to achieve the effects of wide application, high accuracy, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific examples.

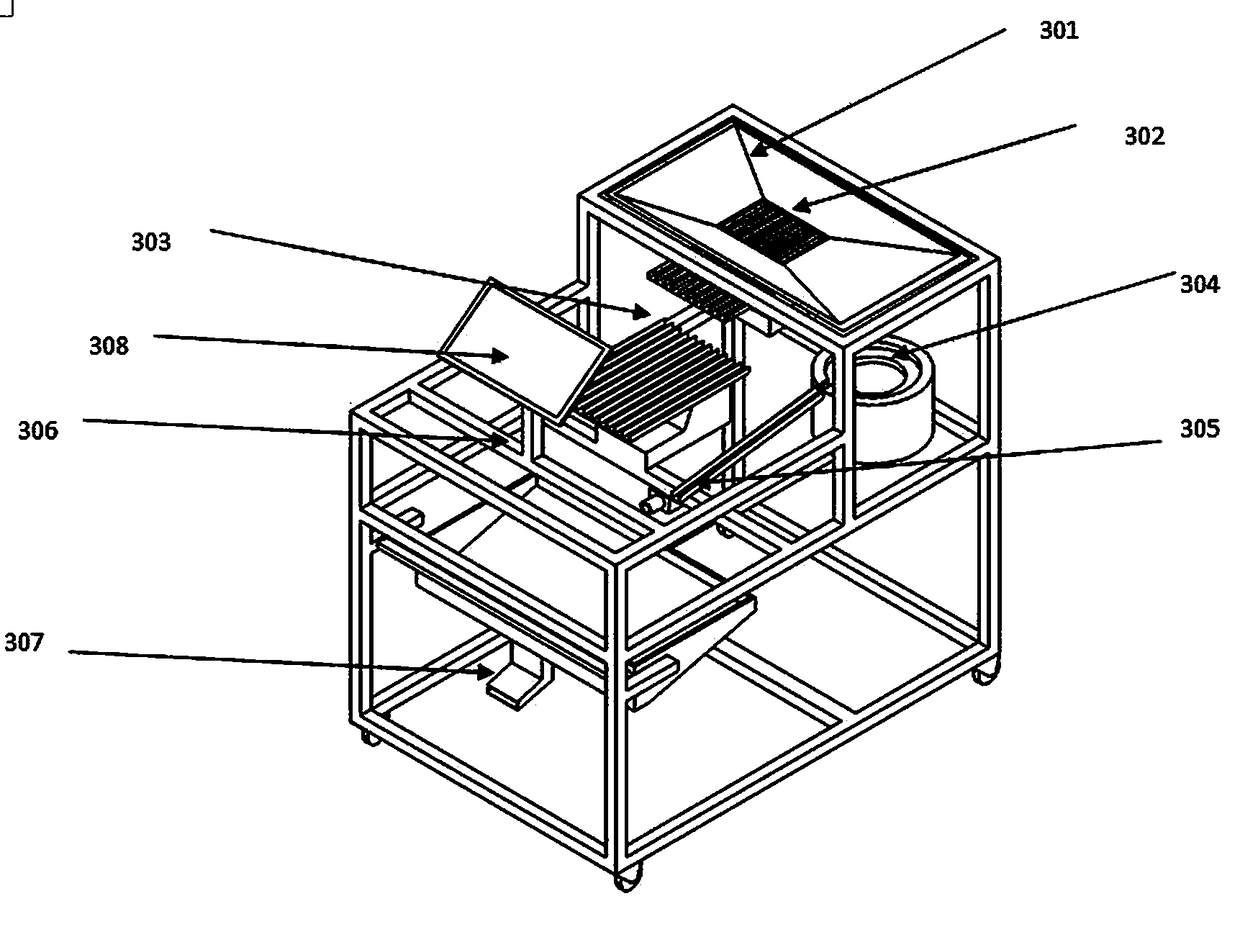

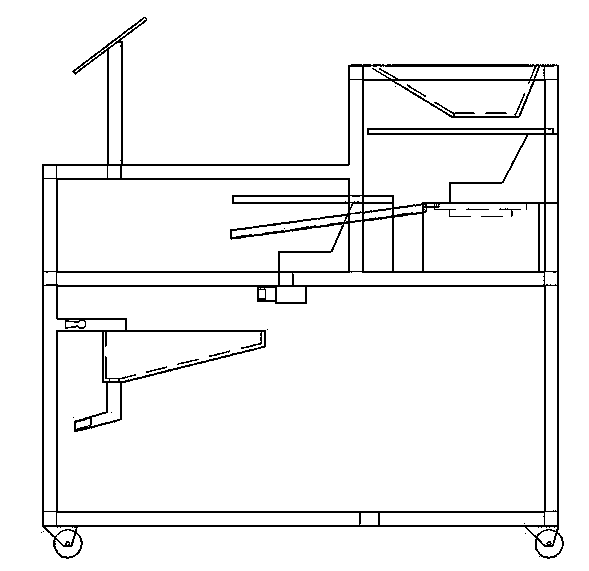

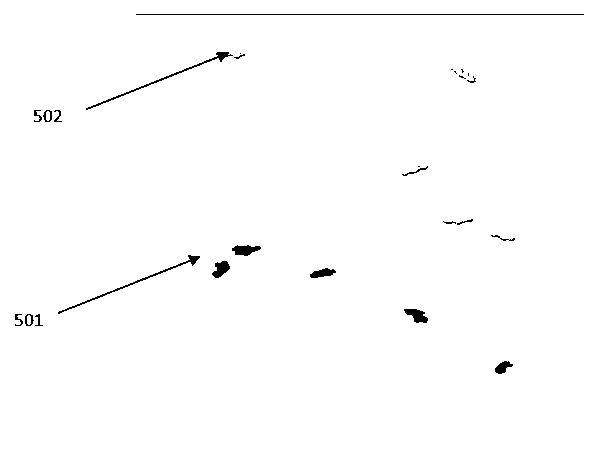

[0022] as attached figure 1 As shown, a counting method and device based on machine vision, the counting method includes two levels: the main counting method and the differential counting method: set the counting target as N1, set a main counting value N2 close to N1 (N2<N1 ), to get N3=N1-N2 (101), and N3 is the differential compensation count value. The counting process is divided into two stages: the main counting (102) of N2 and the differential counting (103) of N3. The two-stage counting methods are equipped with exclusive feeding and vibration mechanisms: the main counting is equipped with a main counting feed hopper and a two-stage vibrating conveyor belt (104), and the differential counting is equipped with a differential counting vibrating plate and a transmission mechanism (105). The two-level counting method is based on the following reasons: due to the conside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com