High-voltage common rail high-speed electromagnet tailstock structure

A high-speed electromagnet and high-voltage common rail technology, applied in electromagnets and other directions, can solve the problems of lack of price competitiveness, high production cost, equipment and tool loss of electromagnet products, saving processing time, reducing material costs, The effect of reducing the overall cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

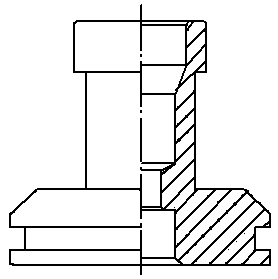

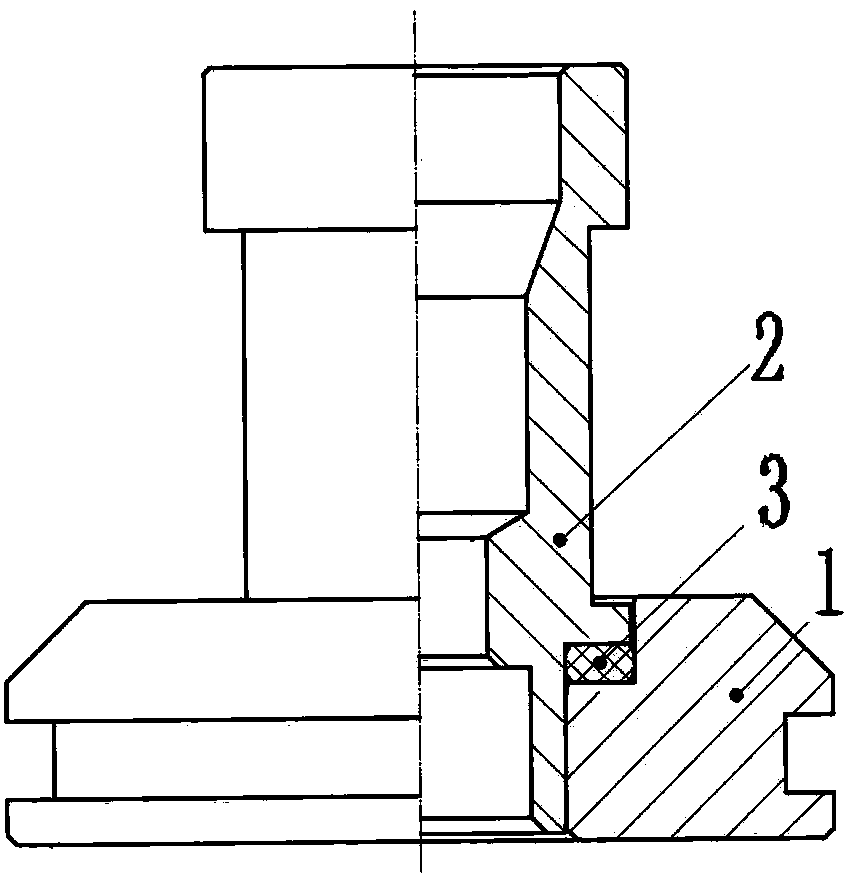

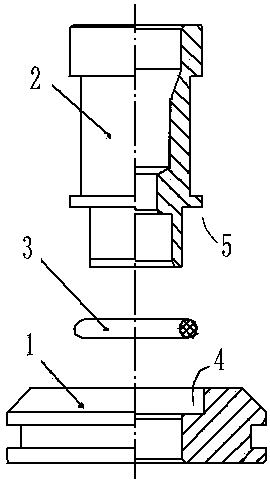

[0013] Such as figure 2 , image 3 As shown, an embodiment of the present invention includes a tailstock body, and the tailstock body includes a base 1 provided with a central through hole, a plug sleeve 2 and a sealing ring 3, and the upper opening of the central through hole is provided with a seat for assembling the sealing ring 3 The annular step 4, the socket 2 is provided with a ring seat 5 matching the annular step 4, the base 1 and the socket 2 are pressed into one body through interference fit, and the sealing ring 3 is assembled between the annular step 4 and the ring seat 5, The sealing ring 3 realizes the sealing of the assembly gap between the base 1 and the socket 2 .

[0014] The principle is: under the condition of meeting the performance requirements of the electromagnet tailstock, the present invention adopts a split assembly structure, which is composed of a base 1 made of metal, a socket 2 made of metal and a sealing ring 3 . The base 1 and the socket 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com