A metallized safety film

A metallized film, safe technology, used in fixed capacitor parts, fixed capacitor electrodes, wire wound capacitors, etc., can solve the problems of large capacitor capacity loss, shortened product life, large unit area, etc., and achieve small capacity loss. , long service life, small unit area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

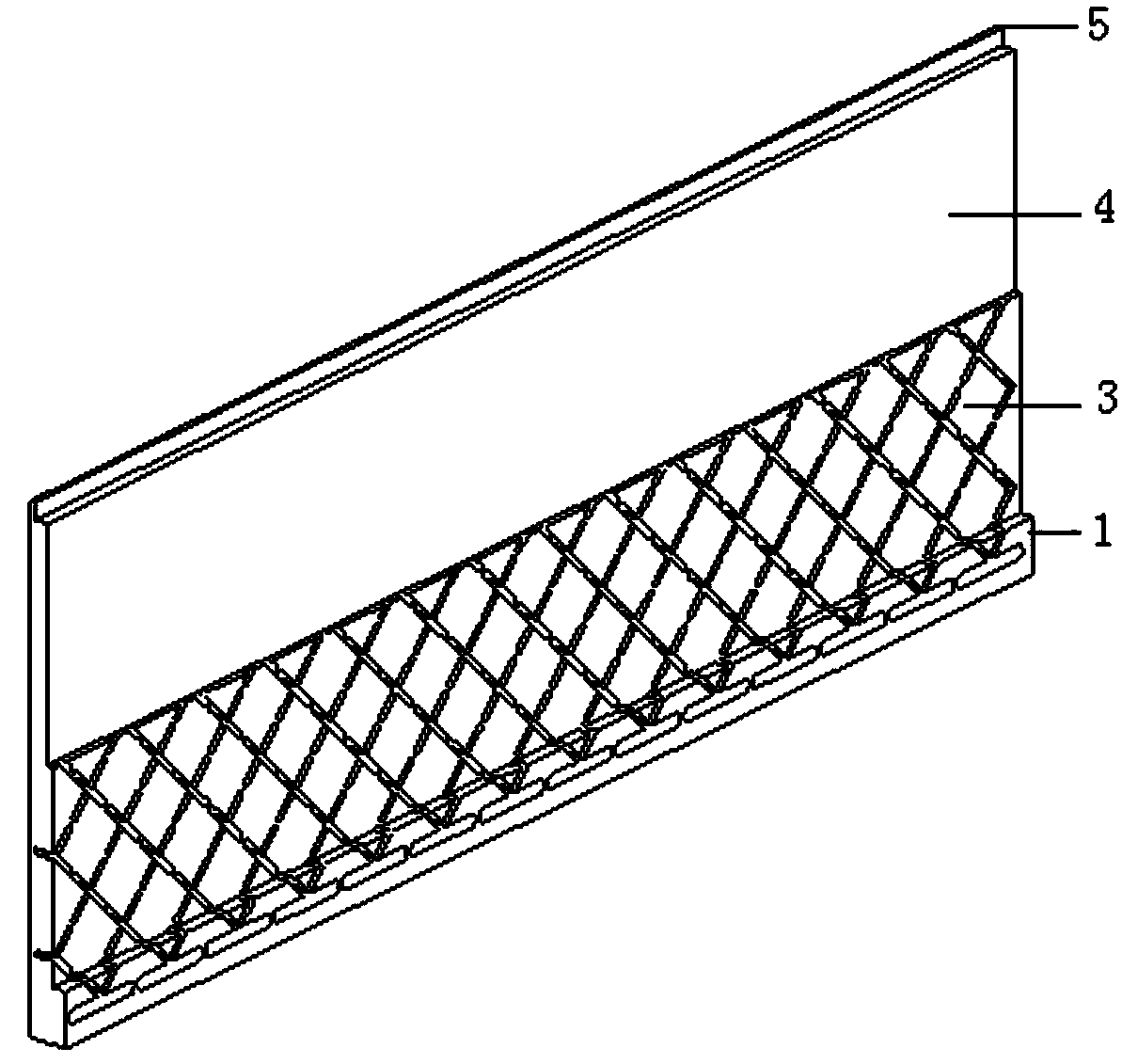

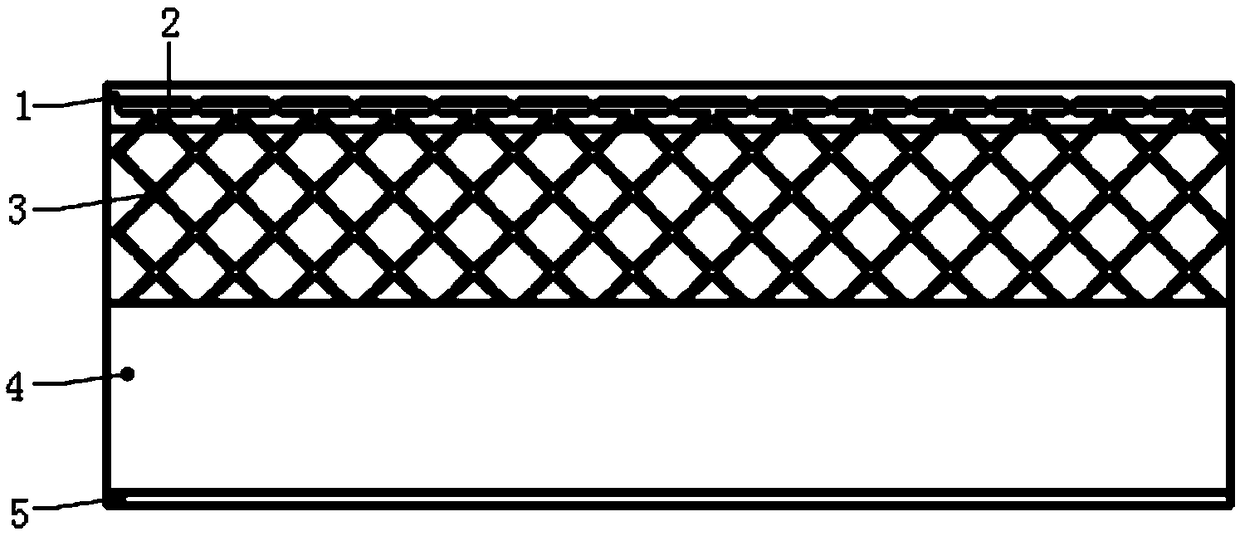

[0024] A metallized security film such as Figure 4-6 , which is formed by stacking double-sided metallized film layers, refer to Figure 1-3 , the metallized film layer comprises a base film and a fully metallized conductive layer 4 located on the base film, a margin area 5 is provided on one side of the base film, and a thickened area 1 is provided on the opposite side of the base film to the margin area 5, The thickened region 1 and the fully metallized conductive layer 4 are separated by the isolation region 2, and the upper part of the fully metallized conductive layer 4 is provided with a conductive mesh region 3 near the thickened region 1, and the conductive mesh region 3 occupies Half of the fully metallized conductive layer 4 . The conductive grid area 3 is provided with a plurality of intersecting and vertical fuses. The fuses divide the conductive grid area 3 to form multiple square units. The fully metallized conductive layer 4 is obtained by evaporating metal al...

Embodiment 2

[0026] In this embodiment, the square resistance of the fully metallized conductive layer 4 is 100Ω / □, the square resistance of the evaporated conductive grid area 3 is 12Ω, and the thickened area 1 is obtained by evaporating metal aluminum or zinc on the base film, and the square resistance is 6Ω, all the other are the same as embodiment 1.

Embodiment 3

[0028] In this embodiment, the square resistance of the fully metallized conductive layer 4 is 50Ω / □, the square resistance of the evaporated conductive grid area 3 is 9Ω, and the thickened area 1 is obtained by evaporating metal aluminum or zinc on the base film, and the square resistance is 4Ω, all the other are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com