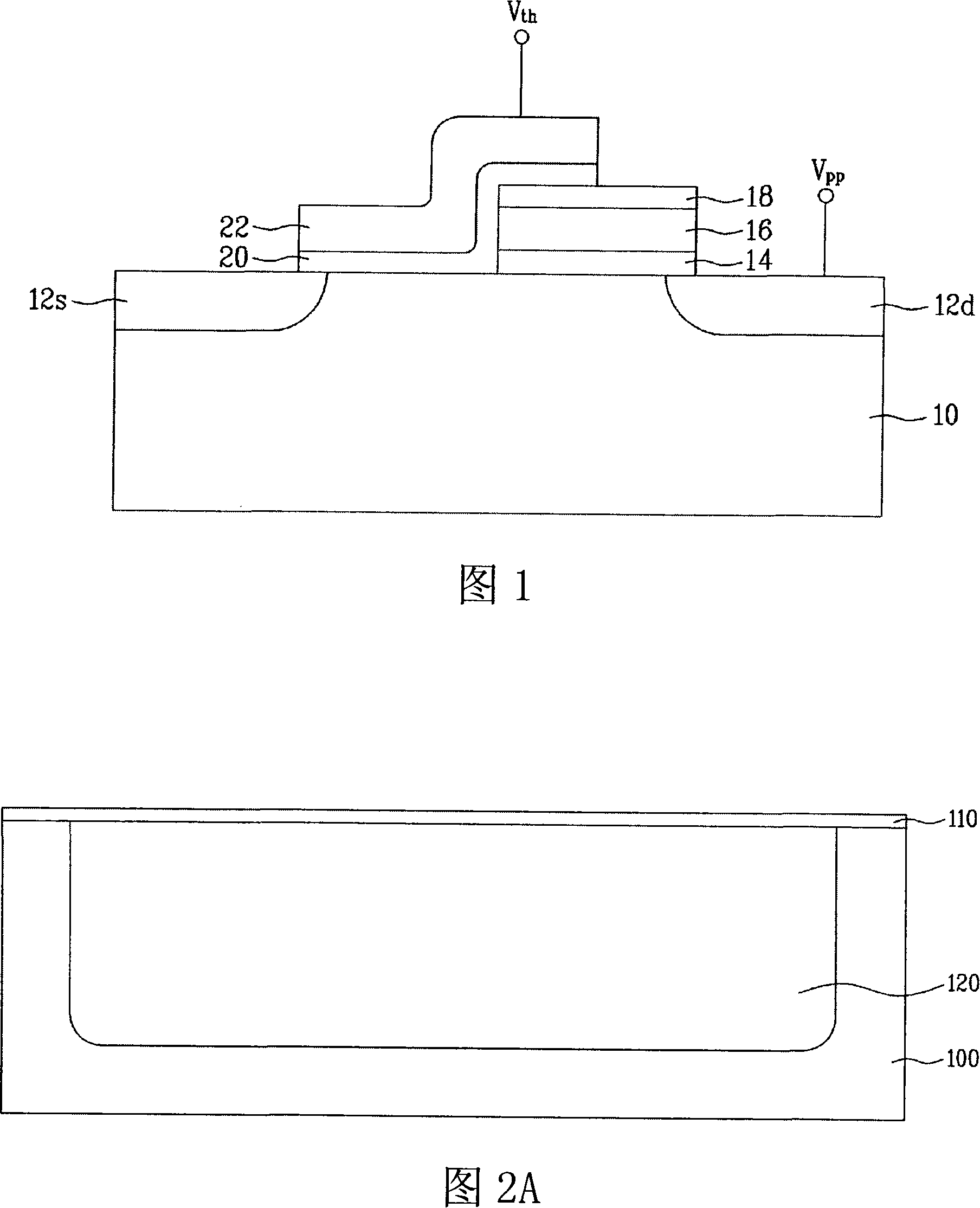

Flash memory device with single-poly structure and method for manufacturing the same

A technology of flash memory device and polycrystalline structure, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., and can solve problems such as unit size reduction, large area, complex unit structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

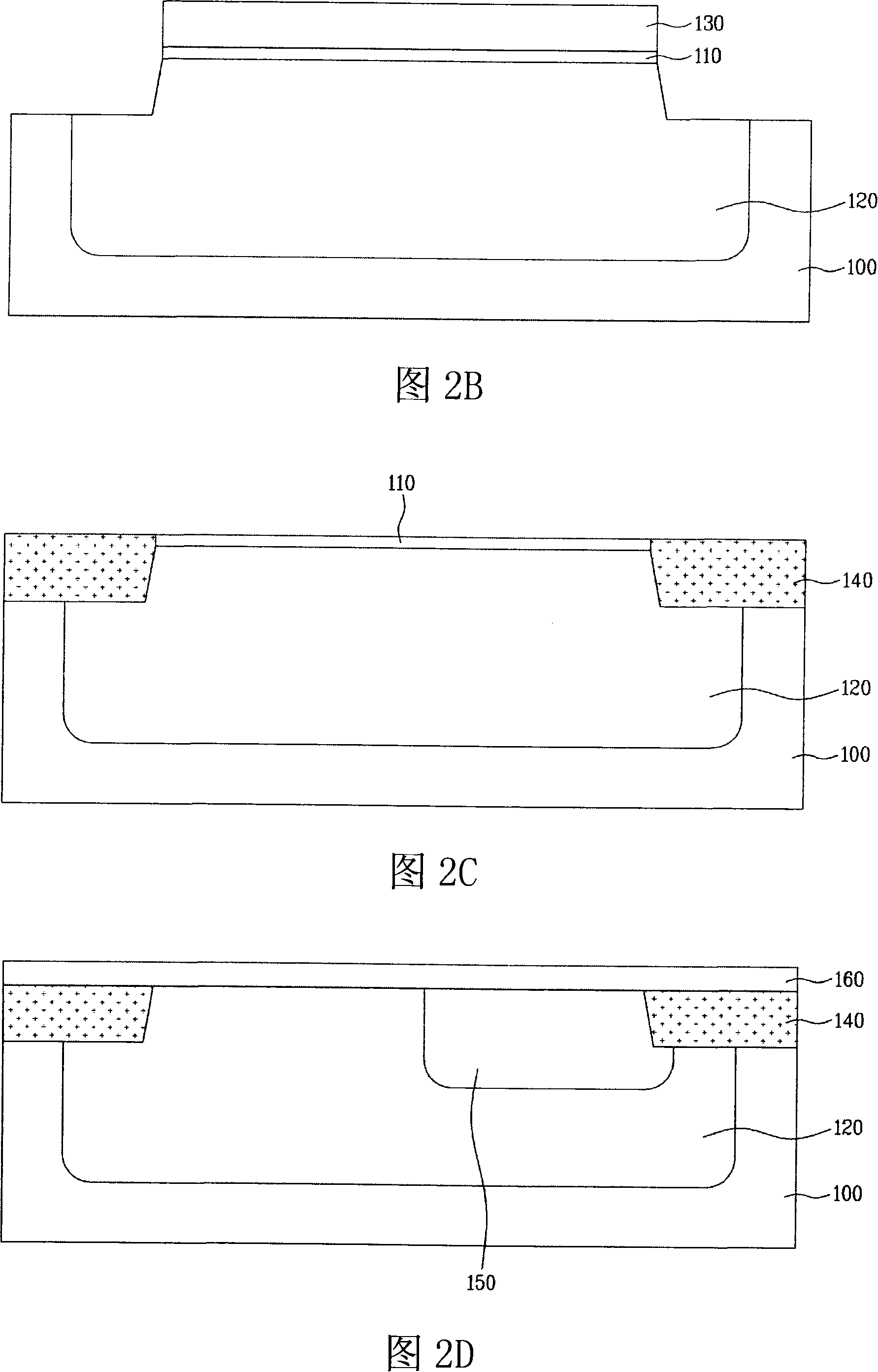

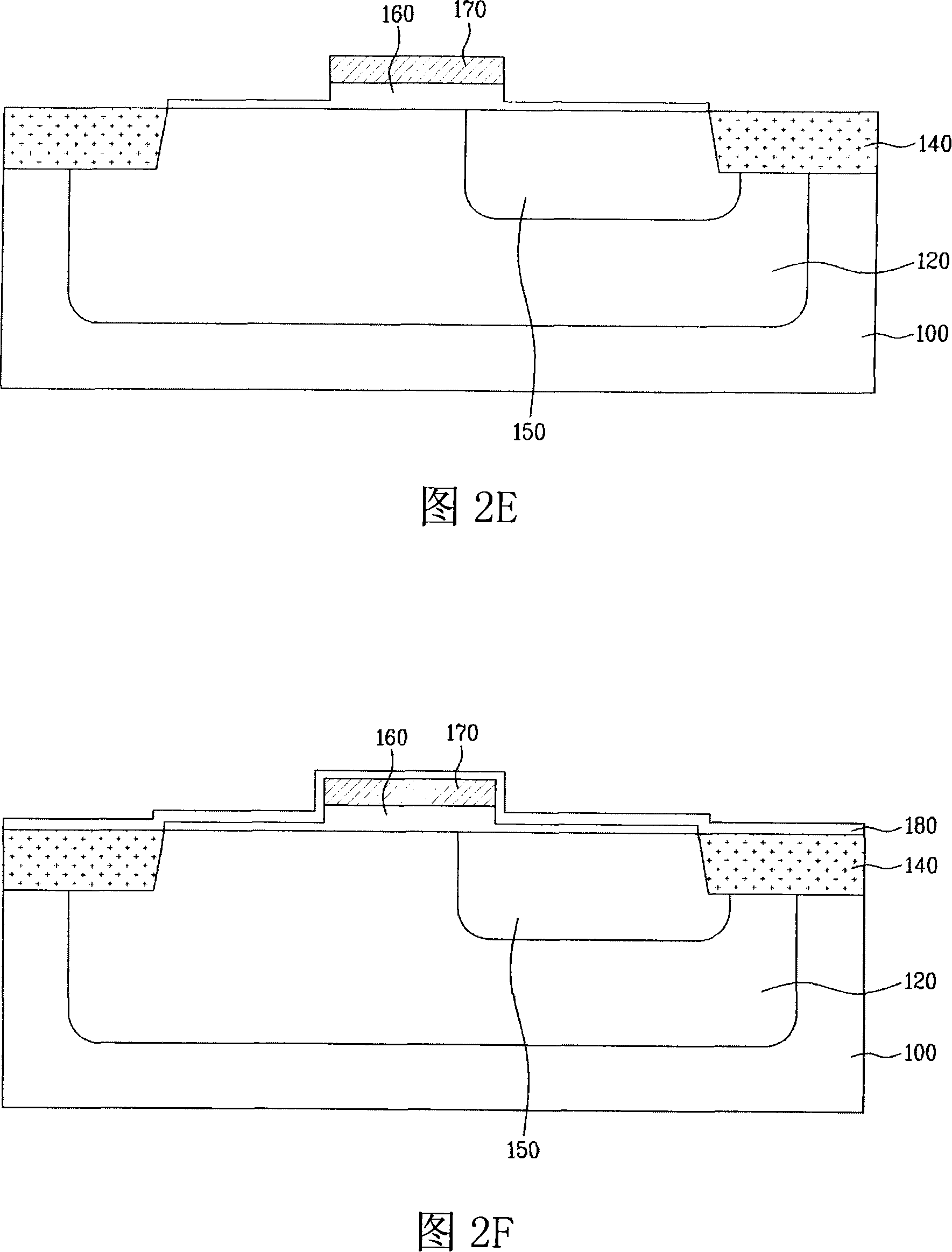

[0020] Embodiments of the present invention will now be described in detail with reference to the embodiments depicted in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0021] Next, a flash memory device having a single-poly crystal structure and a method of manufacturing the same according to a preferred embodiment of the present invention will be described with reference to FIGS. 2A to 2H.

[0022] First, as shown in FIG. 2A , an oxide layer 110 is formed on a semiconductor substrate 100 , and dopants are implanted into the semiconductor substrate 100 to form an HP well or an HN well region 120 .

[0023] Then, to form shallow trench isolation (STI) as shown in FIG. 2B , a photoresist 130 is disposed over regions of the oxide layer 110 other than regions for forming a device insulating layer (not shown). When the oxide layer 110 is etched using the photoresist 130 as an etch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com