Accurate measurement imaging system based on X-ray

An imaging system and optical imaging technology, applied in the field of X-ray imaging, can solve problems such as unstable precision, acquisition of exposure parameters, and low efficiency, and achieve the effects of low manufacturing and use costs, low cost, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] When existing X-ray imaging equipment emits X-rays, irradiation parameters need to be adjusted so as to achieve an optimal irradiation dose. In the prior art, when adjusting the irradiation parameters, it is often adjusted according to the operator's experience and according to different irradiation objects and irradiation parts, so as to determine a range value.

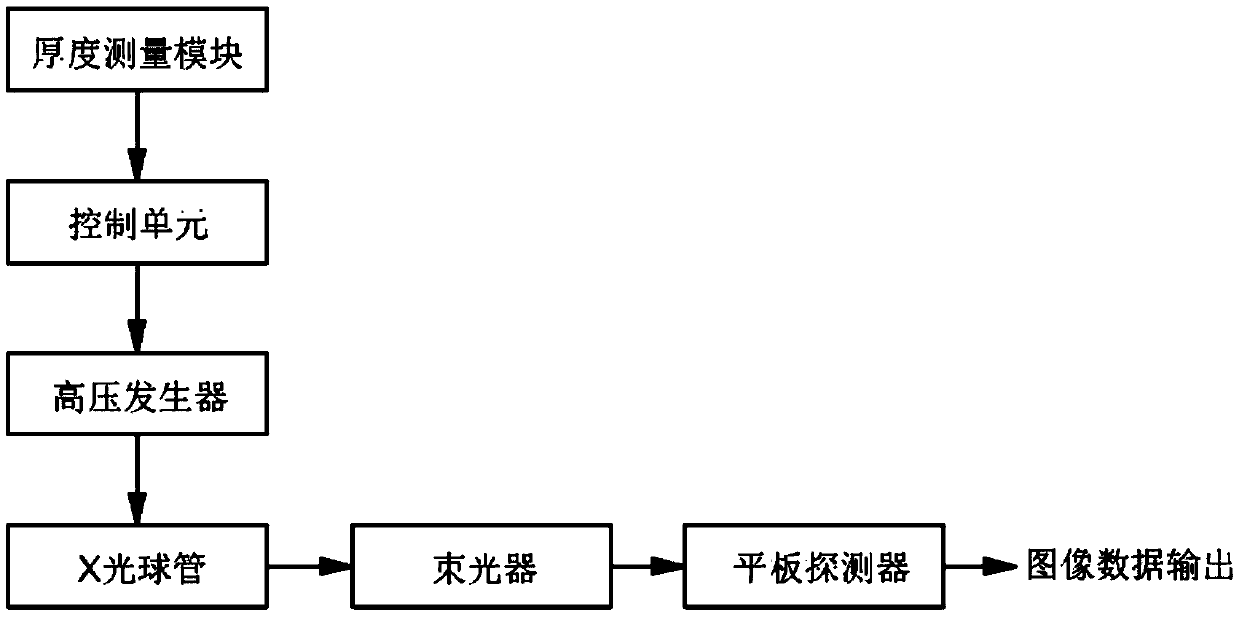

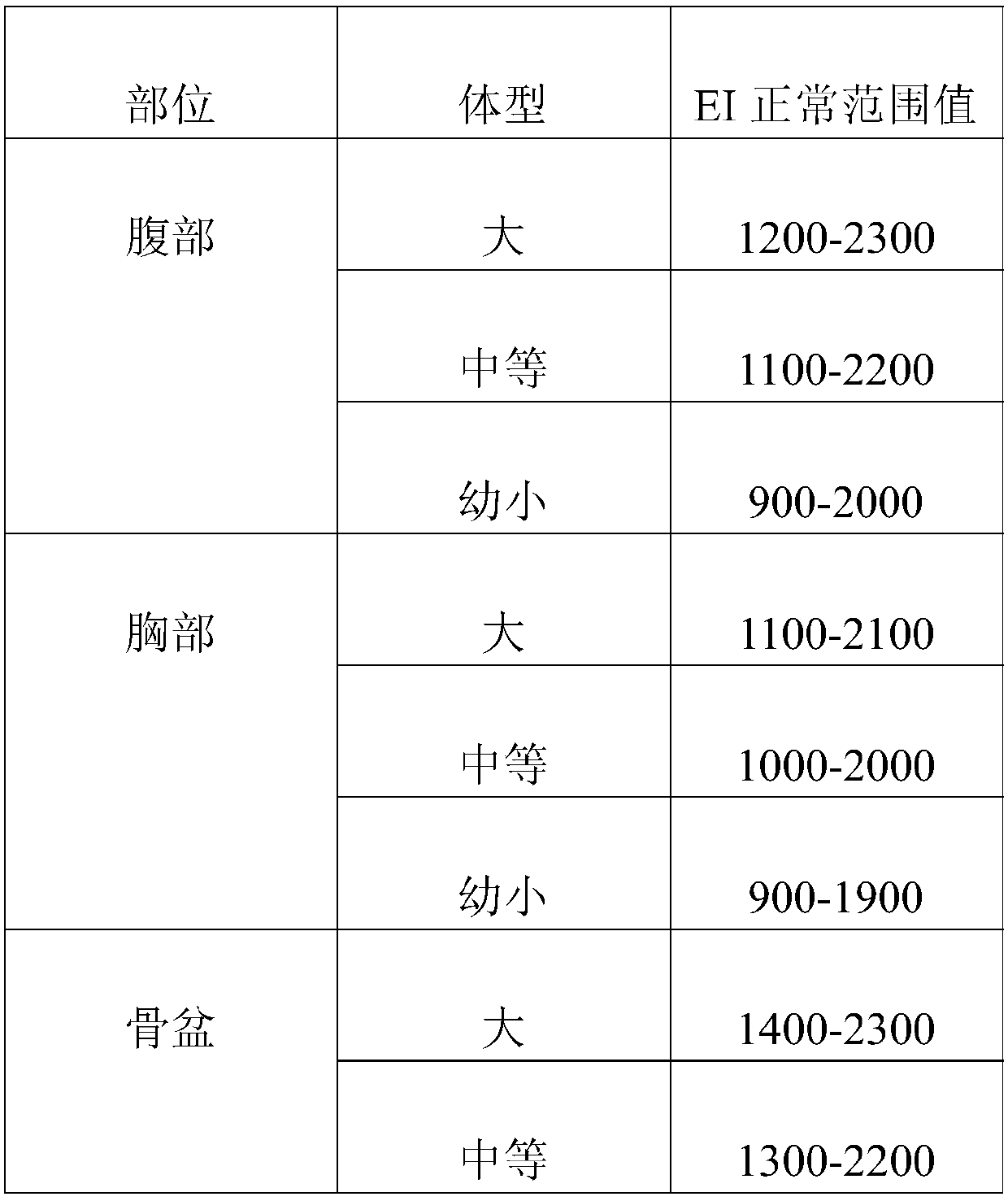

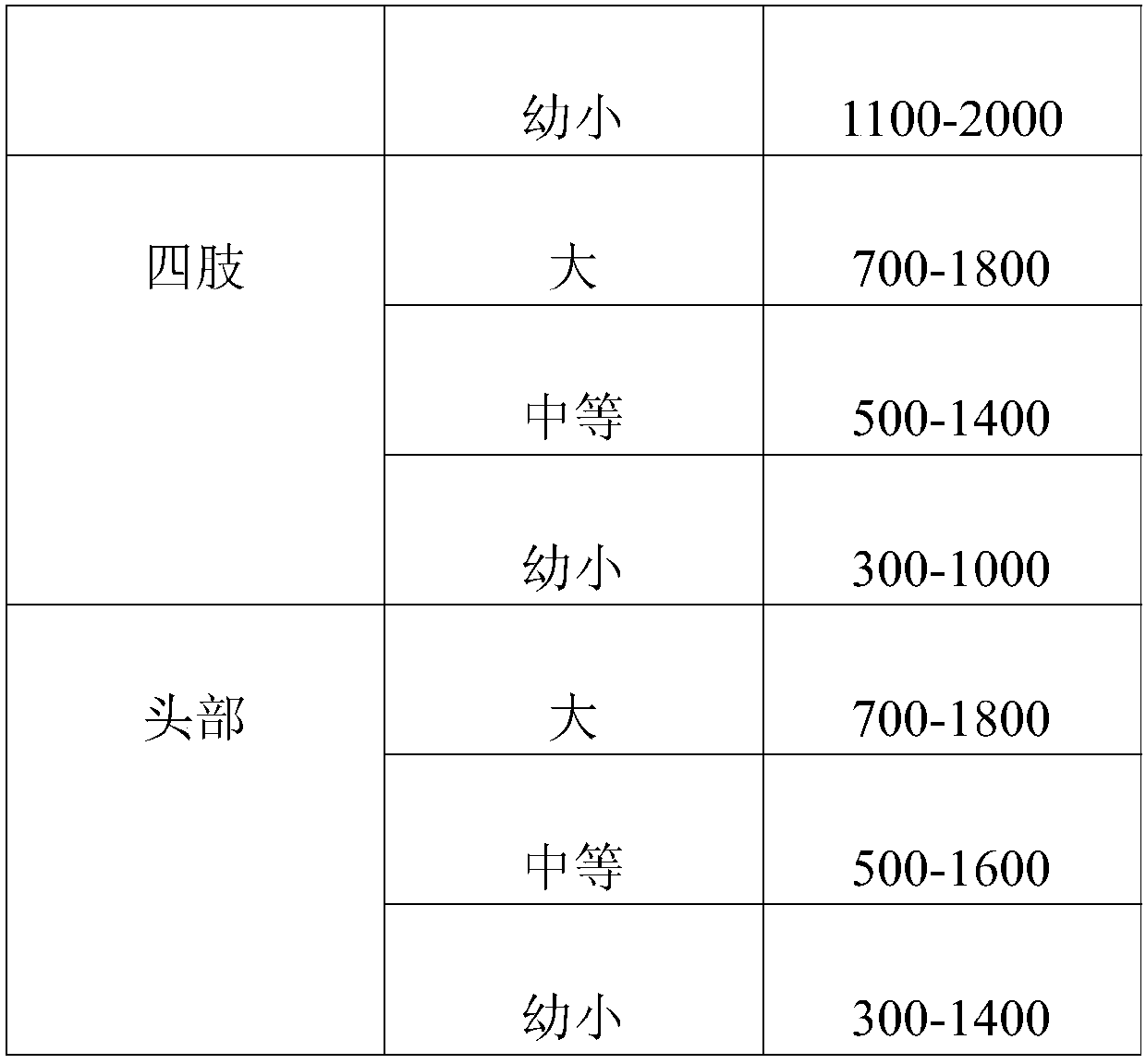

[0033] This embodiment provides an X-ray-based precise measurement and imaging system, including a thickness measurement module for real-time measurement of the thickness of the irradiated object; it also includes a thickness measurement module for receiving the thickness value sent by the thickness measurement module, and bringing the thickness value into the device. The corresponding exposure parameters are obtained from the EI standard range table, and then the X-ray imaging module emits X-rays for imaging. The X-ray imaging module is a complete X-ray imaging device, and the EI standard range table is pre-...

Embodiment 2

[0036] This embodiment provides an X-ray-based precise measurement imaging system, including a thickness measurement module and used to accept the thickness value sent by the thickness measurement module, and bring the thickness value into the established EI standard range table to obtain the corresponding exposure parameters An X-ray imaging module that then emits X-rays for imaging. The X-ray imaging module is a complete X-ray imaging device, and the EI standard range table is pre-written.

[0037] Wherein, the emission parameters include working tube voltage and working tube current product.

[0038] The working tube voltage is the voltage at both ends of the cathode filament and the anode target of the ball tube in the existing X-ray equipment, which can accelerate the electron excitation on the filament and flow to the anode target. The working tube voltage determines the quality of the X-ray, that is, the penetrating power.

[0039] The current product of the working t...

Embodiment 3

[0045] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 2, and the X-ray receiving and imaging module is a flat panel detector.

[0046] The thickness measurement module includes a distance measuring unit coplanar with the X-ray emitting end of the X-ray imaging module and a thickness calculation unit connected to the distance measurement unit. The thickness calculation unit calculates the irradiated object according to the distance value detected by the distance measurement unit in real time. The thickness value is input into the X-ray imaging module.

[0047] The thickness measurement module mainly calculates the distance between the X-ray generating end of the X-ray imaging module and the surface of the irradiated object. Because when the irradiated object is a fixed target, the irradiated object will be fixed on a movable plate and moved to a suitable position, and the cross bullseye on the beam beamer will be aligned with the irradia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com