Filling production line

A production line and cartoning machine technology, applied in packaging, packaging machines, packaging sterilization and other directions, can solve the problems of low production efficiency and high operating costs, save costs, avoid manpower and material resources, and reduce the probability of accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

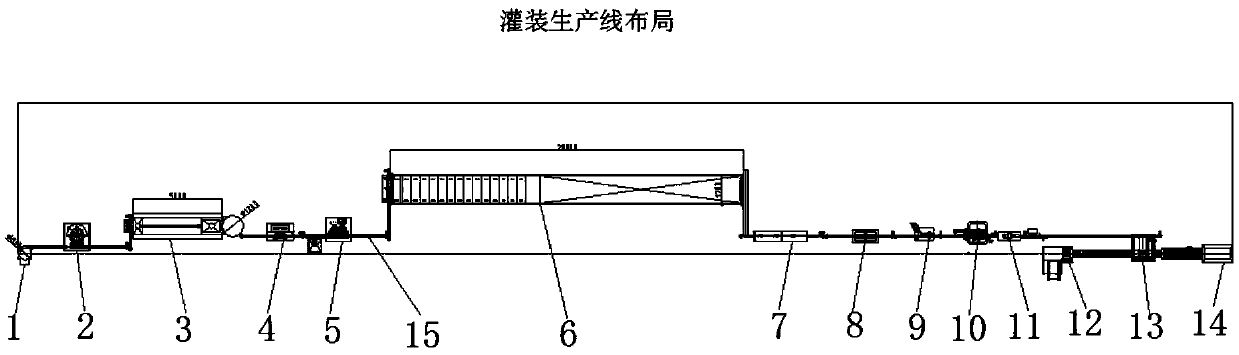

[0016] Such as figure 1 As shown, the present invention provides a filling production line, including a bottle unscrambler 1, a fully automatic rotary bottle washing machine 2, a tunnel type hot air circulation sterilization oven 3, an eight-head servo numerical control filling machine 4, and a cap unscrambling vacuum capping machine 5. Water bath pasteurization machine 6. Spray cleaning machine 7. Air knife drying machine 8. Self-adhesive single-sided labeling machine 9. Film heat shrinking machine 10. Inkjet printer 11. Unpacking machine 12. Fully automatic case packer 13, case sealer 14 and conveyor belt 15, the outlet of bottle unscrambler 1 is connected to one section of conveyor belt 15 by transmission, and the end of one section of conveyor belt 15 far away from bottle unscrambler 1 is connected to the opening at both ends. The automatic rotary bottle washing machine 2 is close to one end of the bottle unscrambler 1, and the other end of the automatic rotary bottle wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com