A Roots blower impeller processing method

A technology of Roots blower and processing method, applied in computer-aided design, instrument, geometric CAD and other directions, can solve the problems of reducing working life, deviating from normal state, seizing and so on, so as to prolong working life, reduce maintenance times and work efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

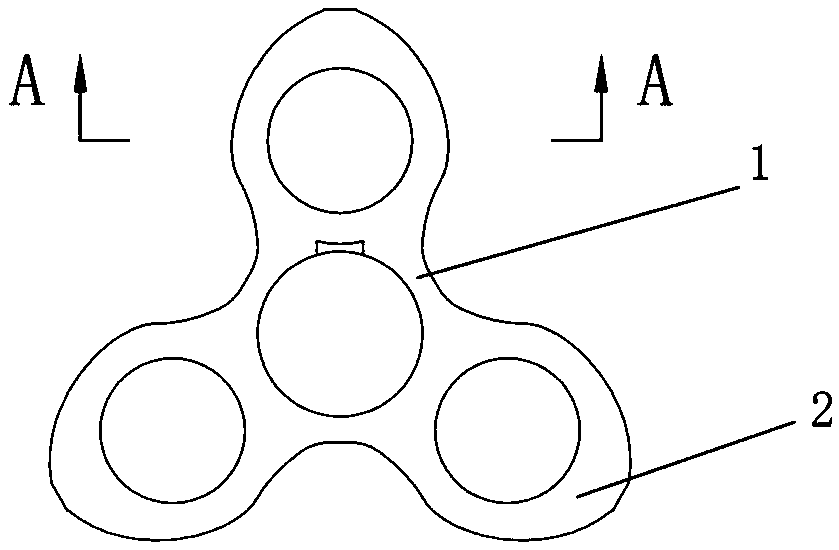

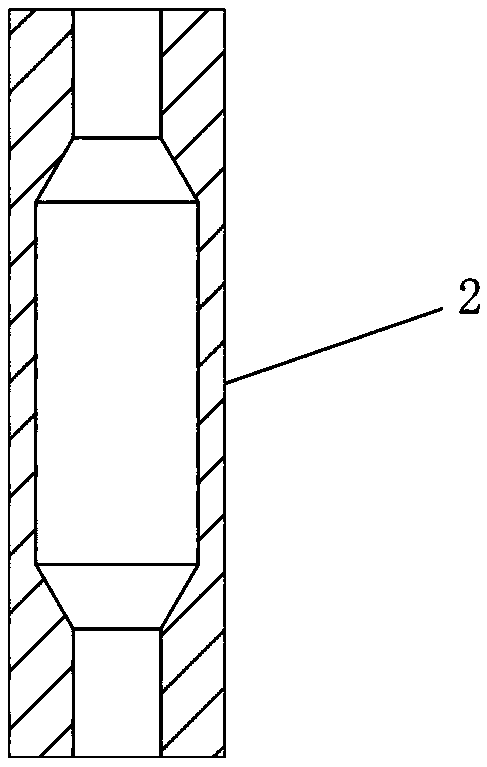

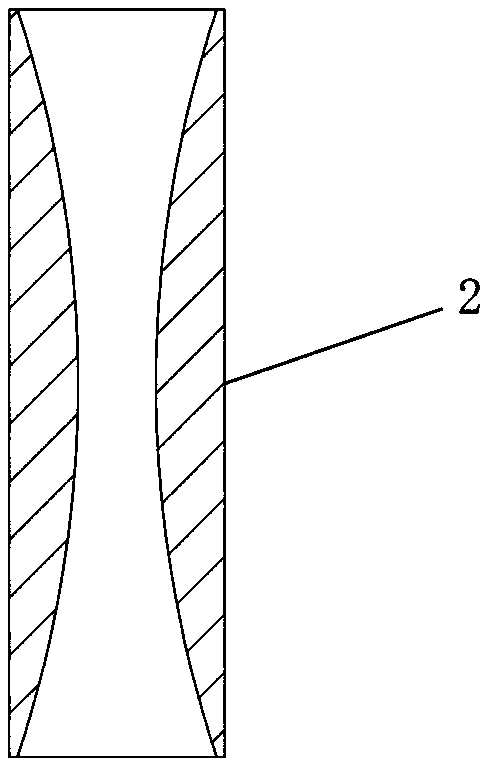

Image

Examples

Embodiment

[0038] As far as object materials are concerned, thermal expansion and contraction are a common phenomenon, but objects with a certain structure will be affected by the size of the structure, and the deformation of each structure after thermal expansion and contraction is inconsistent, that is, due to the size constraints of the shape, After thermal deformation, the size of the body may increase or decrease, and may remain unchanged without being affected by temperature; such as a circular part, the thermal deformation of the inner hole diameter is affected by the outer diameter. When the ratio of the inner and outer diameters reaches a certain When the value is high, its inner diameter may shrink or remain unchanged, that is, there is a "critical size"; and different inner pore structures have different thermal deformations, and there will also be a certain "critical structure" that makes the object as a whole less affected by temperature. Based on the above principles, the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com