Efficient composite photocatalyst α-fe in response to visible light 2 o 3 /in 2 the s 3 preparation method

A technology of -fe2o3 and composite light, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as poor separation, low conduction band position, and low photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

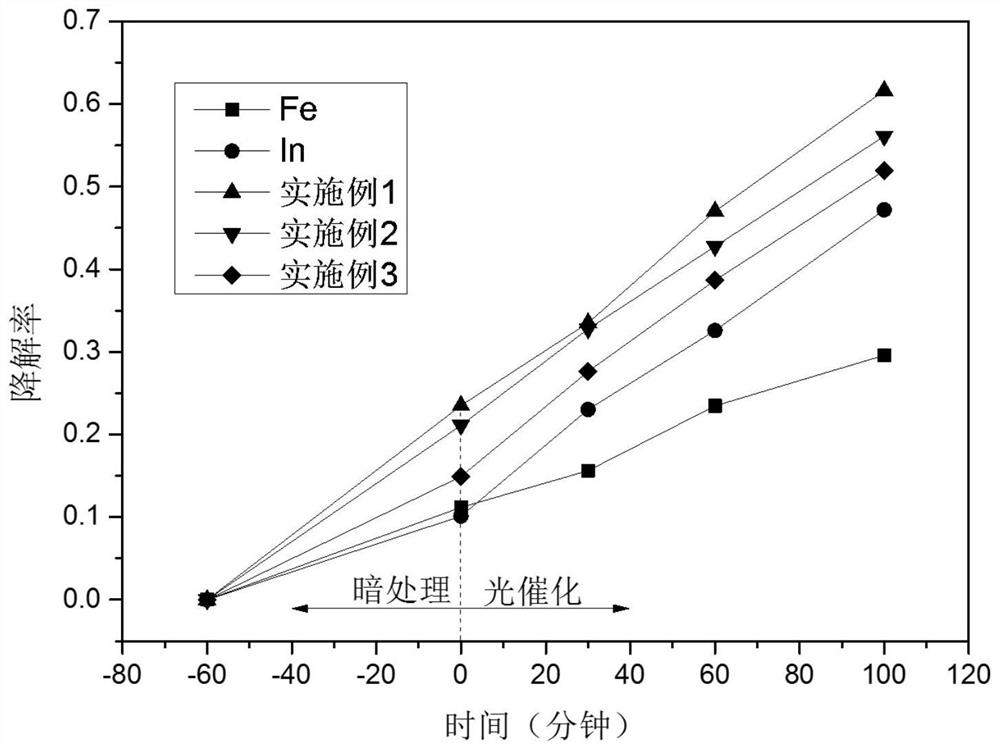

[0030] High-efficiency composite photocatalyst α-Fe responsive to visible light of the present invention 2 o 3 / In 2 S 3 The preparation method comprises the steps of: weighing 0.003mol α-Fe prepared by hydrothermal method 2 o 3 Nanoparticles, drop 10mL molar concentration of indium nitrate solution (wherein, n(α-Fe 2 o 3 ): n(In(NO 3 ) 3 ·5H 2 (2)=9:2), ultrasonic 15min disperses evenly, then slowly drips 20mL molar concentration under stirring and is the sodium sulfide solution of 0.083mol / L (wherein, n(In(NO 3 ) 3 ·5H 2 O): n(Na 2 S)=1:2.5) into the above suspension, the pH value of the solid suspension was maintained at 3, and then it was transferred to an autoclave and placed in an oven at 180°C for aging for 24h. The obtained solid phase was washed with water until neutral, dried at 60°C for 5 hours, and ground for later use to obtain α-Fe 2 o 3 / In 2 S 3 composite photocatalyst.

[0031] Among them, α-Fe 2 o 3 The preparation method of nanoparticle co...

Embodiment 2

[0033] High-efficiency composite photocatalyst α-Fe responsive to visible light of the present invention 2 o 3 / In 2 S 3 The preparation method comprises the steps of: weighing 0.0032mol α-Fe prepared by hydrothermal method 2 o 3 Nanoparticles, drop 5mL molar concentration of 0.0067mol / L indium nitrate solution (wherein, n(α-Fe 2 o 3 ): n(In(NO 3 ) 3 ·5H 2 (2)=19:2), ultrasonic 15min disperses evenly, then slowly drips 20mL of sodium sulfide solution (wherein, n(In(NO 3 ) 3 ·5H 2 O):n(Na 2 S)=1:2.5) into the above suspension, the pH value of the solid suspension was maintained at 3, and then it was transferred to an autoclave and placed in an oven at 180°C for aging for 24 hours. The obtained solid phase was washed with water until neutral, dried at 60°C for 5 hours, and ground for later use to obtain α-Fe 2 o 3 / In 2 S 3 composite photocatalyst.

[0034] Among them, α-Fe 2 o 3 The preparation method of nanoparticle comprises the steps: get 16.16g Fe(NO 3 )...

Embodiment 3

[0036] High-efficiency composite photocatalyst α-Fe responsive to visible light of the present invention 2 o 3 / In 2 S 3 The preparation method comprises the steps of: weighing 0.0028mol α-Fe prepared by hydrothermal method 2 o 3 Nanoparticles, drop 15mL molar concentration of 0.0067mol / L indium nitrate solution (wherein, n(α-Fe 2 o 3 ):n(In(NO 3 ) 3 ·5H 2 (2)=17:6), ultrasonic 15min disperses evenly, then slowly drips 20mL molar concentration of 0.125mol / L sodium sulfide solution under stirring (wherein, n(In(NO 3 ) 3 ·5H 2 O):n(Na 2 S)=1:2.5) into the above suspension, the pH value of the solid suspension was maintained at 3, and then it was transferred to an autoclave and placed in an oven at 180°C for aging for 24 hours. The obtained solid phase was washed with water until neutral, dried at 60°C for 5 hours, and ground for later use to obtain α-Fe 2 o 3 / In 2 S 3 composite photocatalyst.

[0037] Among them, α-Fe 2 o 3 The preparation method of nanoparti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com