Microcomputer voltage electric ultrasonic transducer with etching hole and sectioned upper electrode

A block-etching and hole-etching technology, which is applied in the direction of fluid using vibration, can solve the problems of low signal-to-noise ratio and low sensitivity, and achieve the effects of improving sensitivity, reducing stiffness, and reducing parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

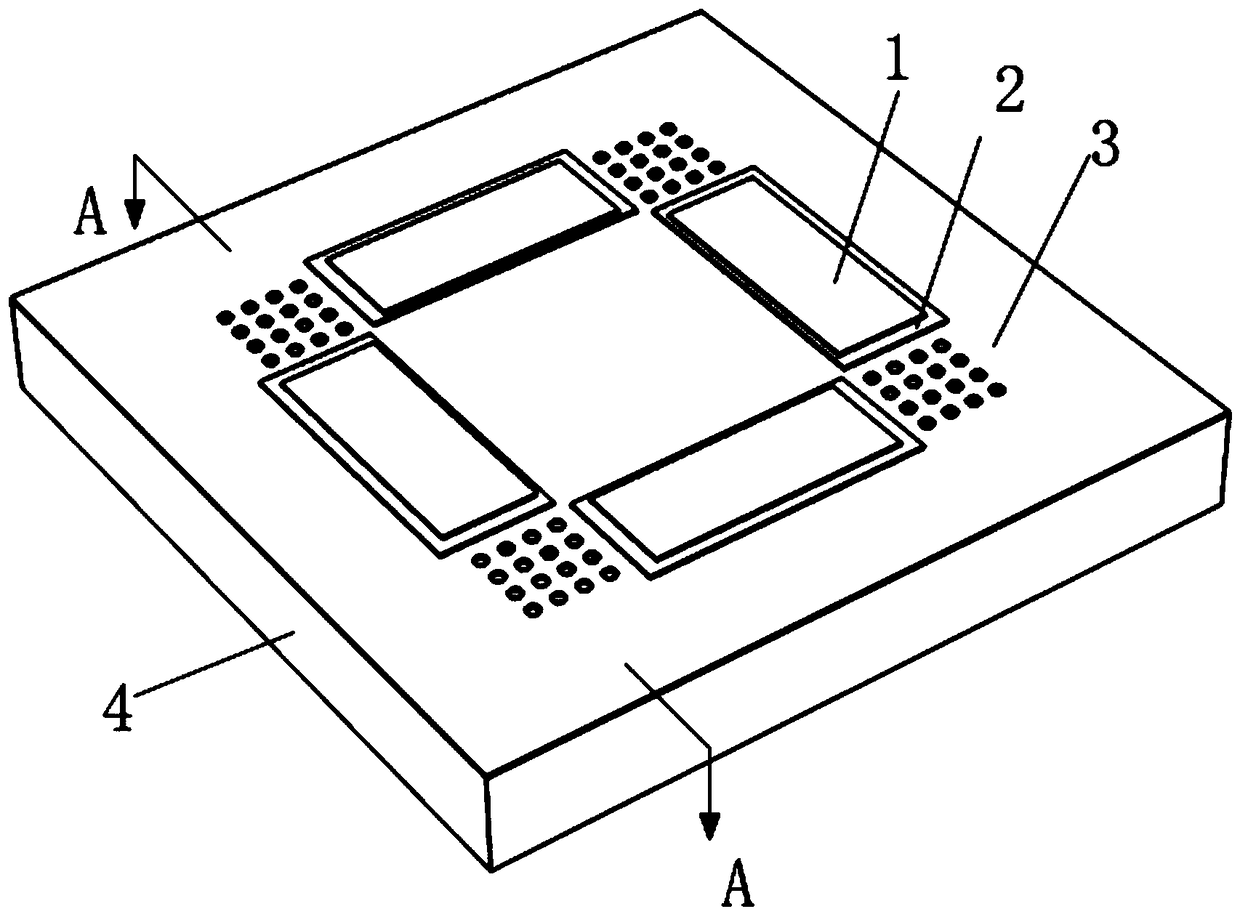

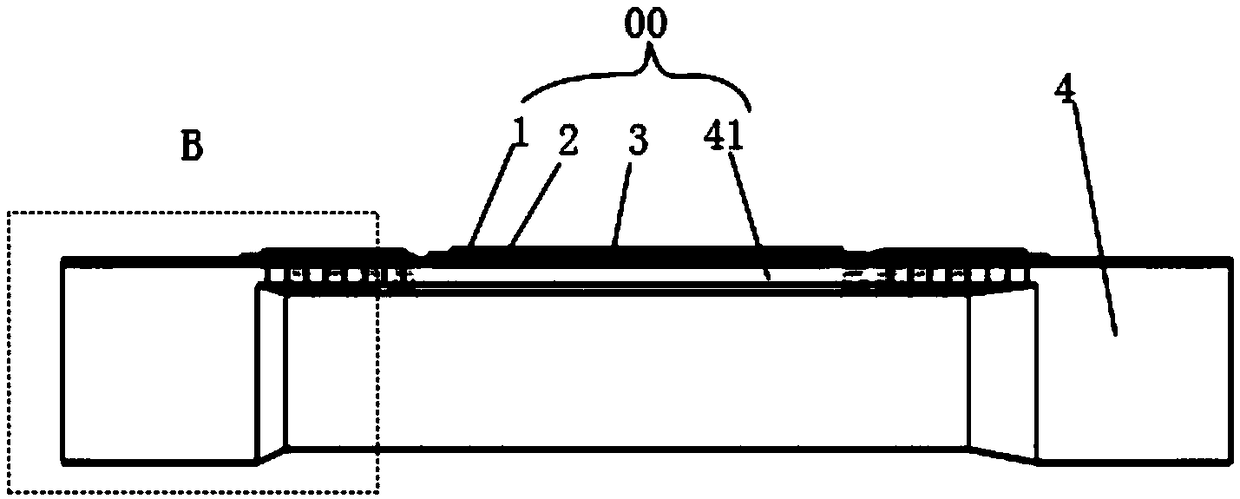

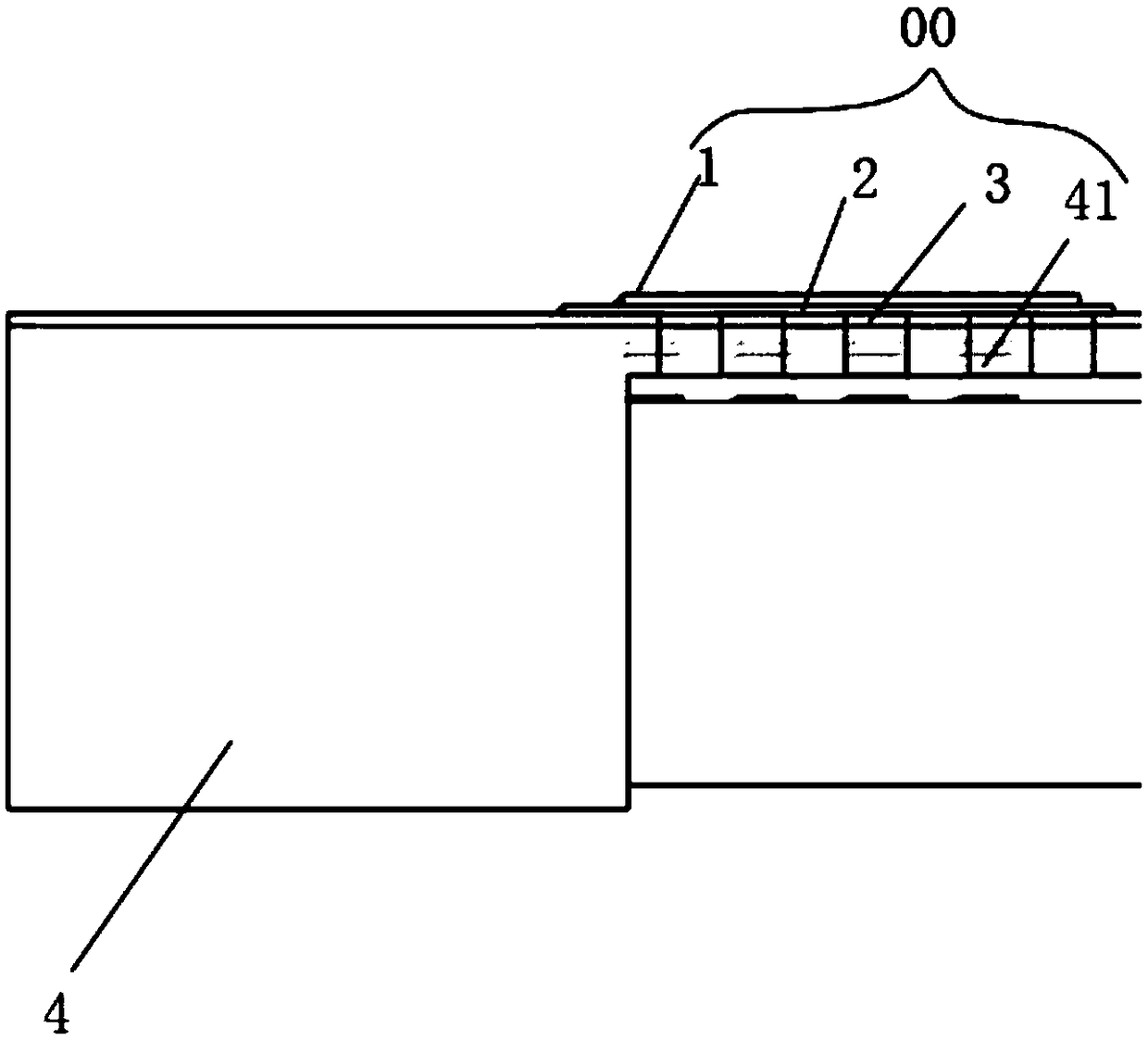

[0029] Such as Figure 1~3 As shown, a microcomputer piezoelectric ultrasonic transducer with etched holes and segmented upper electrodes mainly includes a substrate 4 , a bottom electrode 3 , a piezoelectric layer 2 and an upper electrode 1 . A groove-shaped cavity is selectively etched on the back of the substrate 4 to form an elastic structural layer 41 with a certain thickness on the front of the substrate 4, and the unetched part of the substrate 4 around the elastic structural layer 41 forms a fixed end (anchor end). The bottom electrode 3 , the piezoelectric layer 2 and the upper electrode 1 are sequentially stacked on the front of the elastic structural lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com