Automatic plastic section material perforating machine

A technology of plastic profiles and punching machines, which is applied in metal processing and other directions, can solve the problems that affect the processing progress, the processing speed cannot be reached, and the processing deviation of soft plastic profiles, etc., so as to ensure the processing accuracy, small movement resistance, and position easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

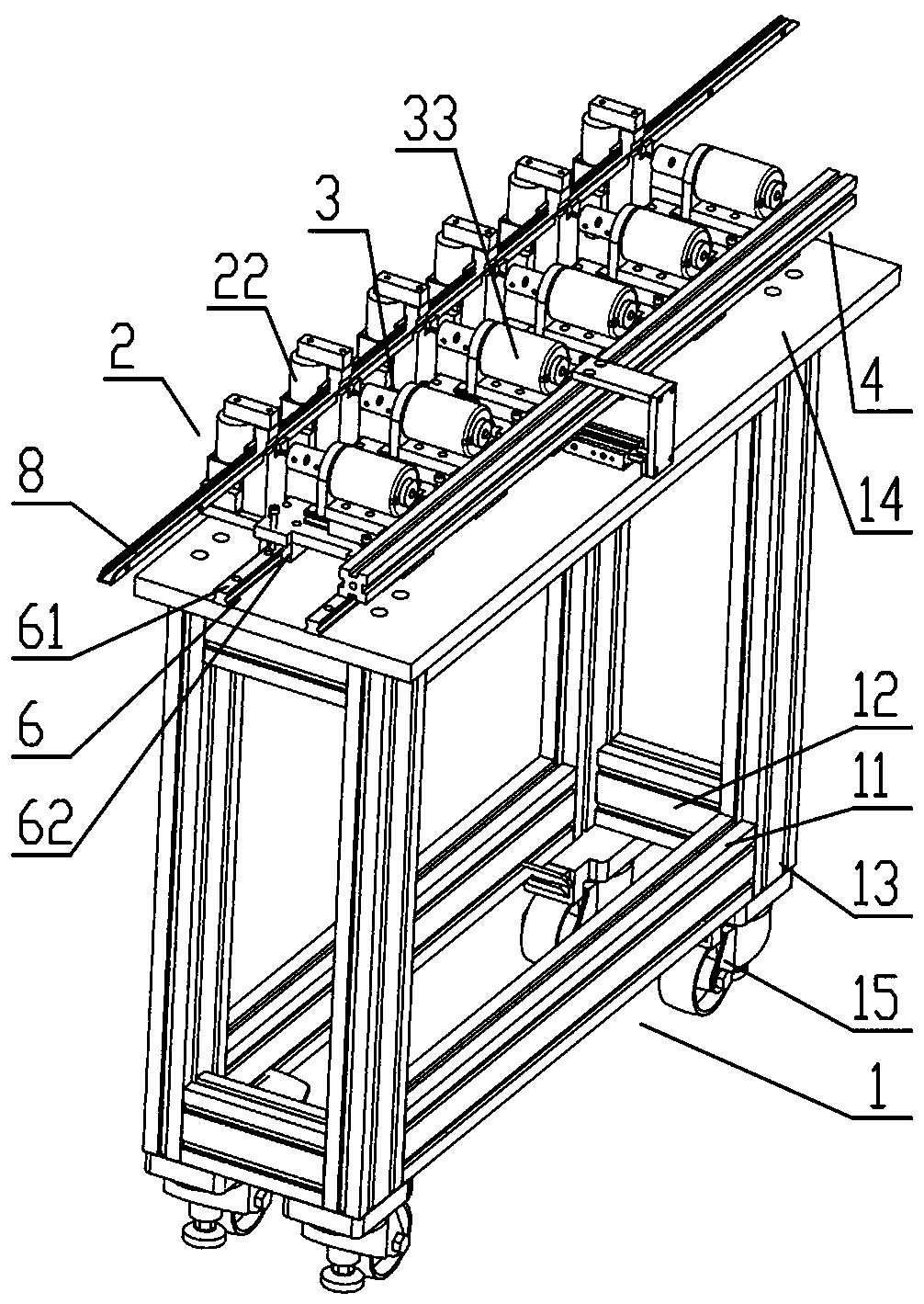

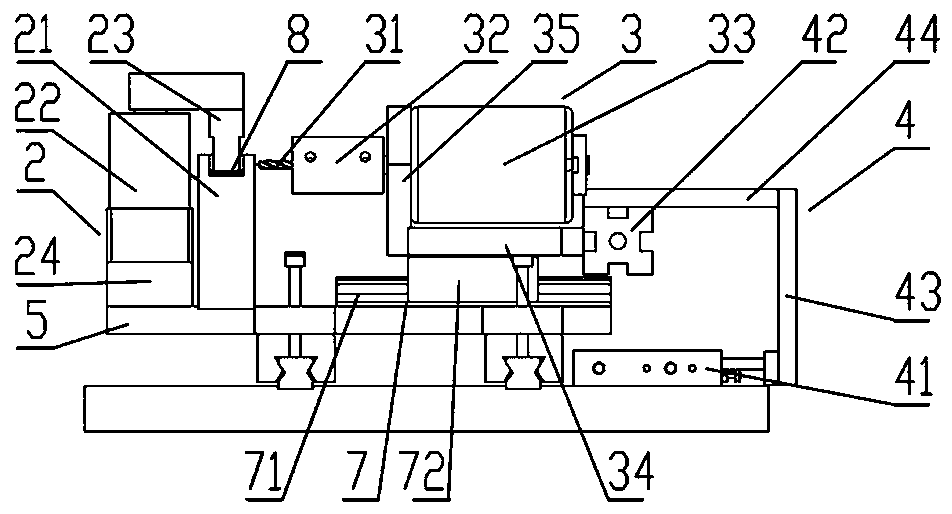

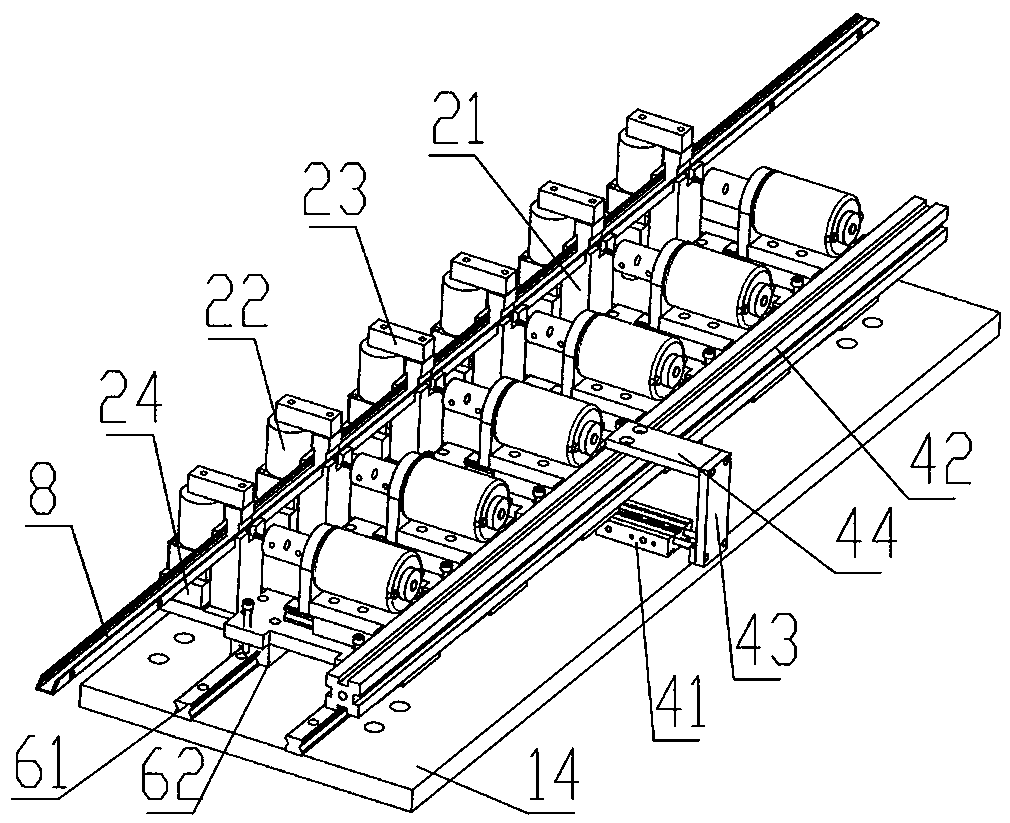

[0028] Such as Figure 1 to Figure 3 Shown is the first embodiment of the automatic punching machine for plastic profiles of the present invention, which includes a fixed bracket 1 for supporting, a pressing device 2 that can move downward to compress plastic profiles 8, and a tool for punching plastic profiles 8. The drilling device 3, the adjusting device for adjusting the position of the drilling device 3 and the pressing device 2, and the pushing device 4 for driving the drilling device 3 to advance and withdraw the knife, the pressing device 2 and the pushing device 4 are all located in On the fixed support 1, the pressing device 2 is connected with the drilling device 3 through the first fixed plate 5, and the drilling device 3 is connected with the pushing device 4. An adjustment device and a second adjustment device 7 located between the first fixing plate 5 and the punching device; the pressing device 2 is provided with a holding groove 21 for placing plastic profiles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com