Automatic sensing and dispatching method of robot welding wire in welding workshop

A robot and welding wire technology, applied in the field of automatic communication in the welding workshop, can solve the problems of consuming physical strength and time of operators, reducing production efficiency, etc., and achieve the effect of improving production continuity and efficiency, increasing production efficiency, and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiment of the present invention is illustrated below by specific examples

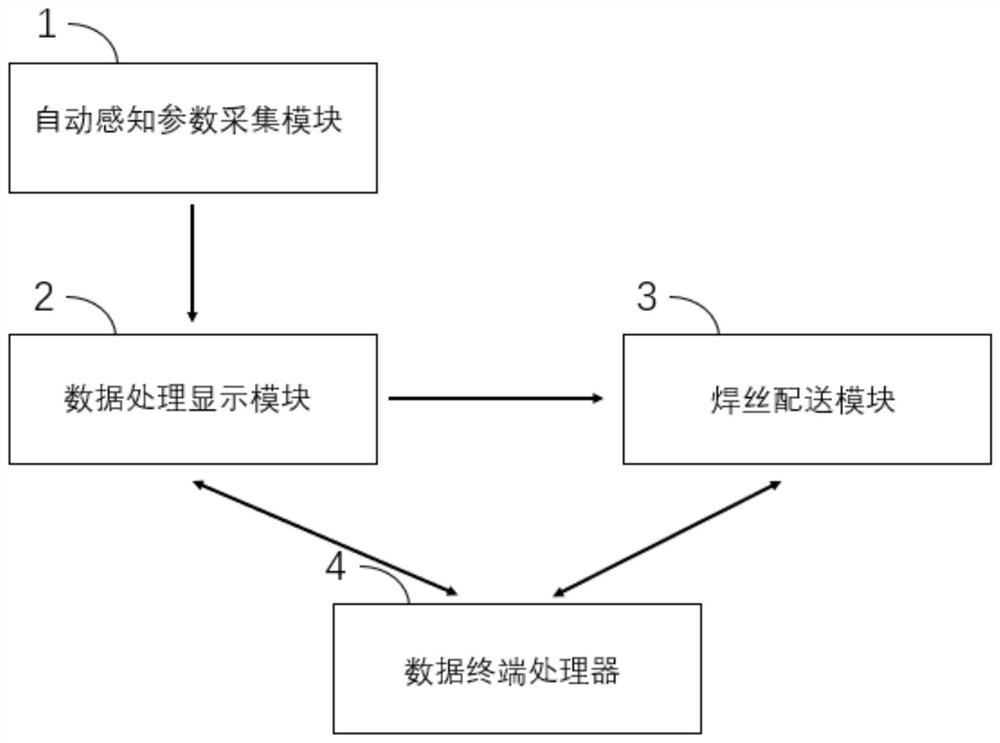

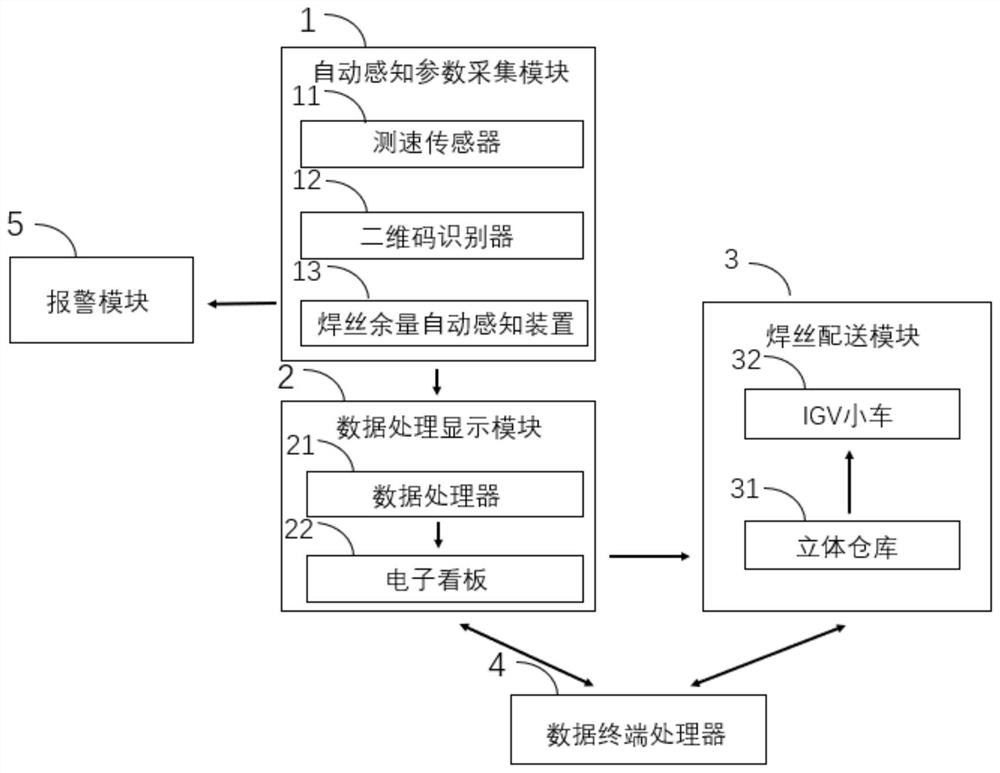

[0028] see figure 1 , the present invention provides a structural block diagram of a robot welding wire automatic transfer system for a welding workshop, including:

[0029] The Internet of Things system in the workshop is used for information collection and information exchange of each station in the welding workshop. Information collection is to collect parameters such as welding parameters, welding wire models, and welding wire allowances used in the welding workshop during the production process of the welding workshop. , Information exchange, used to connect various devices in the entire transportation system to realize the automation of welding wire transportation. The devices connected to the entire network system include: automatic sensing parameter acquisition module 1, data processing and display module 2, welding wire distribution module 3, and data terminal processor 4.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com