Reverse osmosis membrane structure, filter element and water purifier

A technology of reverse osmosis membrane and reverse osmosis membrane module, which is applied in the field of water treatment, can solve the problems of easy fouling and short life of the filter element, and achieve the effect of slowing down the concentration polarization, prolonging the service life and reducing the tendency of fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

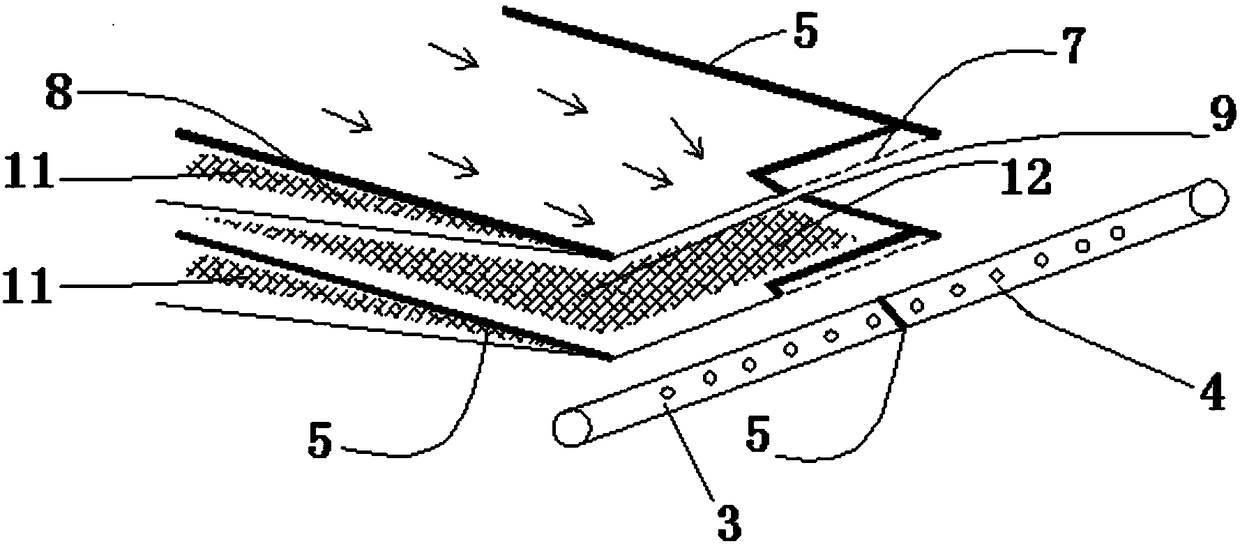

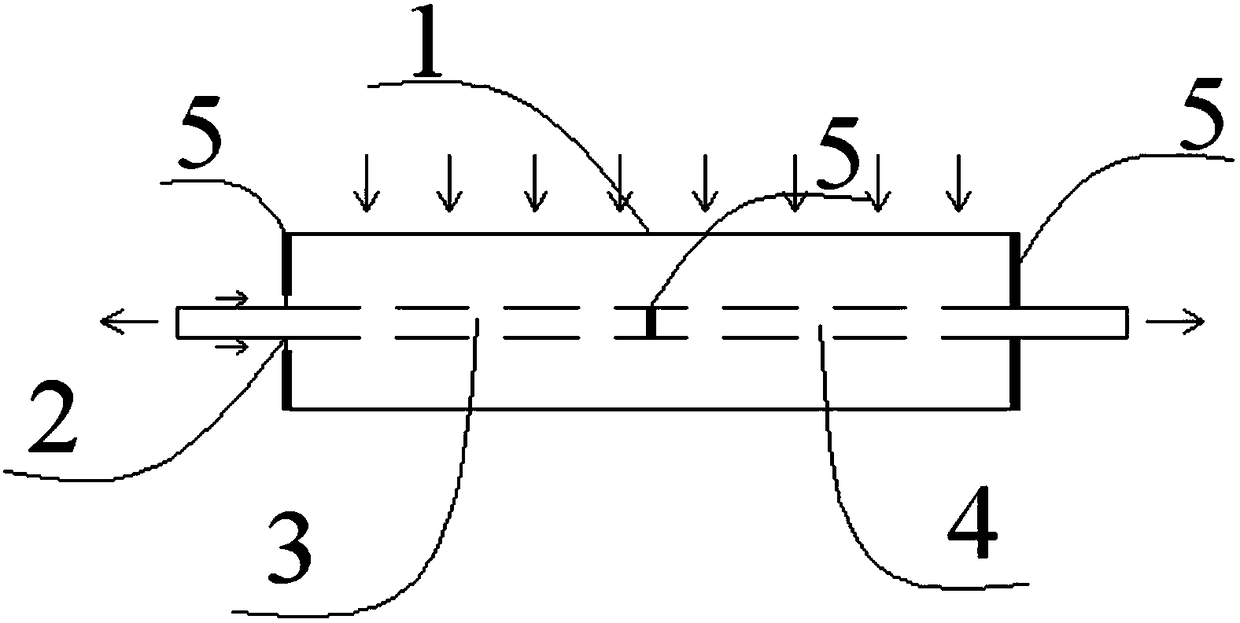

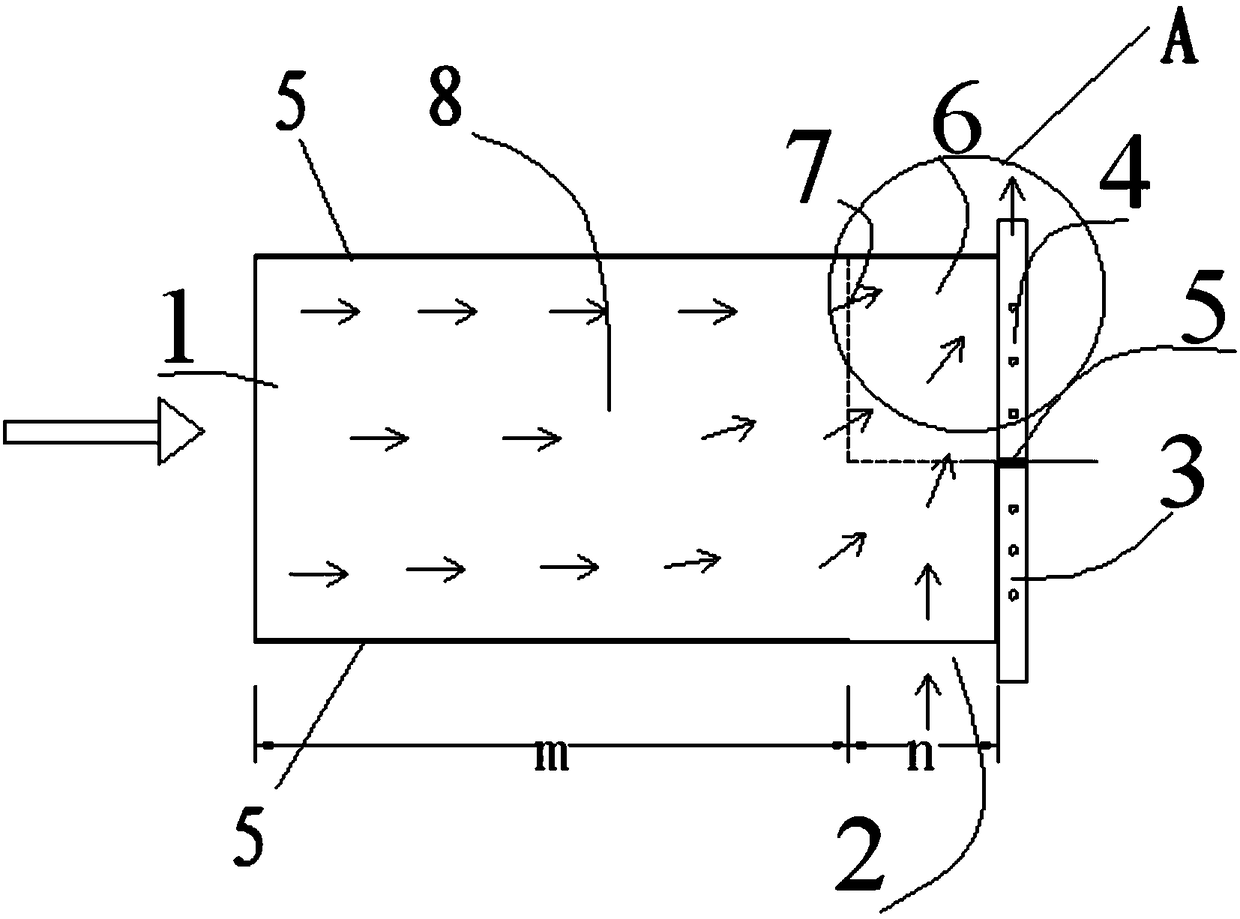

[0044] This embodiment provides a reverse osmosis membrane structure, such as figure 1 and figure 2 As shown, it includes a central pipe and a reverse osmosis membrane module that can be rolled around the central pipe. The central pipe includes an isolated concentrated water section 4 and a pure water section 3, the side wall of the concentrated water section 4 has a concentrated water inlet, and the end of the concentrated water section 4 far away from the pure water section 3 forms concentrated water Outlet 6, the side wall of the pure water section 3 has a central pipe pure water inlet, and the end of the pure water section 3 far away from the concentrated water section 4 forms a central pipe pure water outlet. The reverse osmosis membrane assembly is composed of a reverse osmosis membrane 10, a raw water diversion net 11 and a pure water diversion net 12 stacked in a certain order and rolled around a central tube. A raw water flow channel 8 communicating with the water in...

Embodiment 2

[0050] This embodiment provides a filter element, including a reverse osmosis membrane structure provided in the above embodiment. Since the raw water flow channel 8 in the reverse osmosis membrane structure is longer, the surface velocity of the reverse osmosis membrane 10 is higher than that of ordinary membrane elements. , can effectively slow down the concentration polarization of the membrane surface and delay the structure of the membrane surface, so the service life of the filter element is longer.

Embodiment 3

[0052] This embodiment provides a water purifier, including a filter element provided in Embodiment 2. Since the water purifier has a long service life of the filter element, the period for replacing the filter element can be shortened, thereby saving costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com