Top-mounting coke oven mixed coal and formulation method

A technology for blending coal and coke ovens, applied in coke ovens, charging devices, petroleum industry, etc., can solve the problems of rough proportioning, affecting the stability of blast furnaces, and unreasonable composition of a single type of coal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following describes the specific embodiments of the present invention in further detail through the description of the embodiments, the purpose is to help those skilled in the art have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and to help them. Implement.

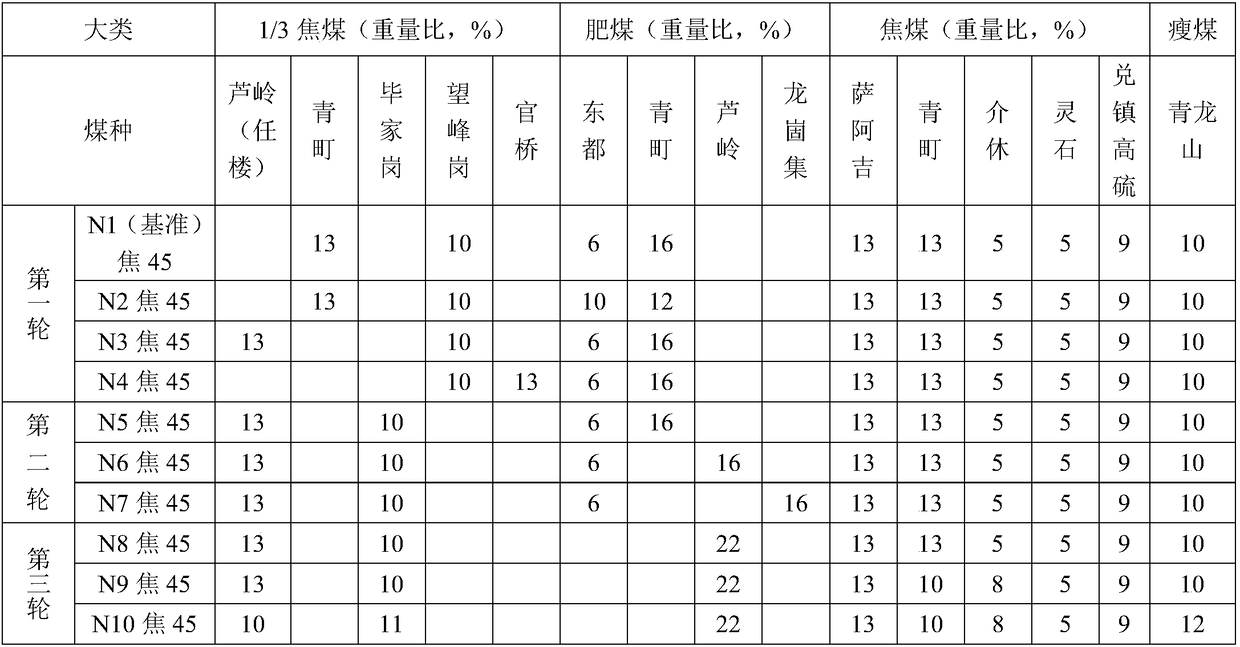

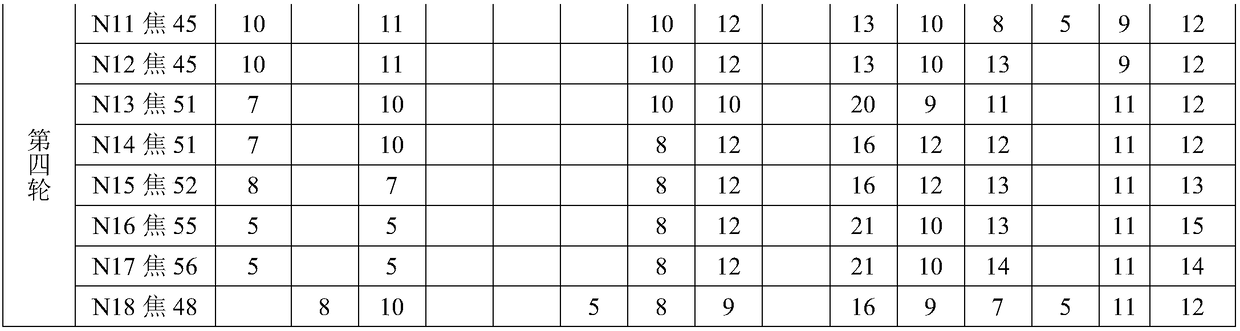

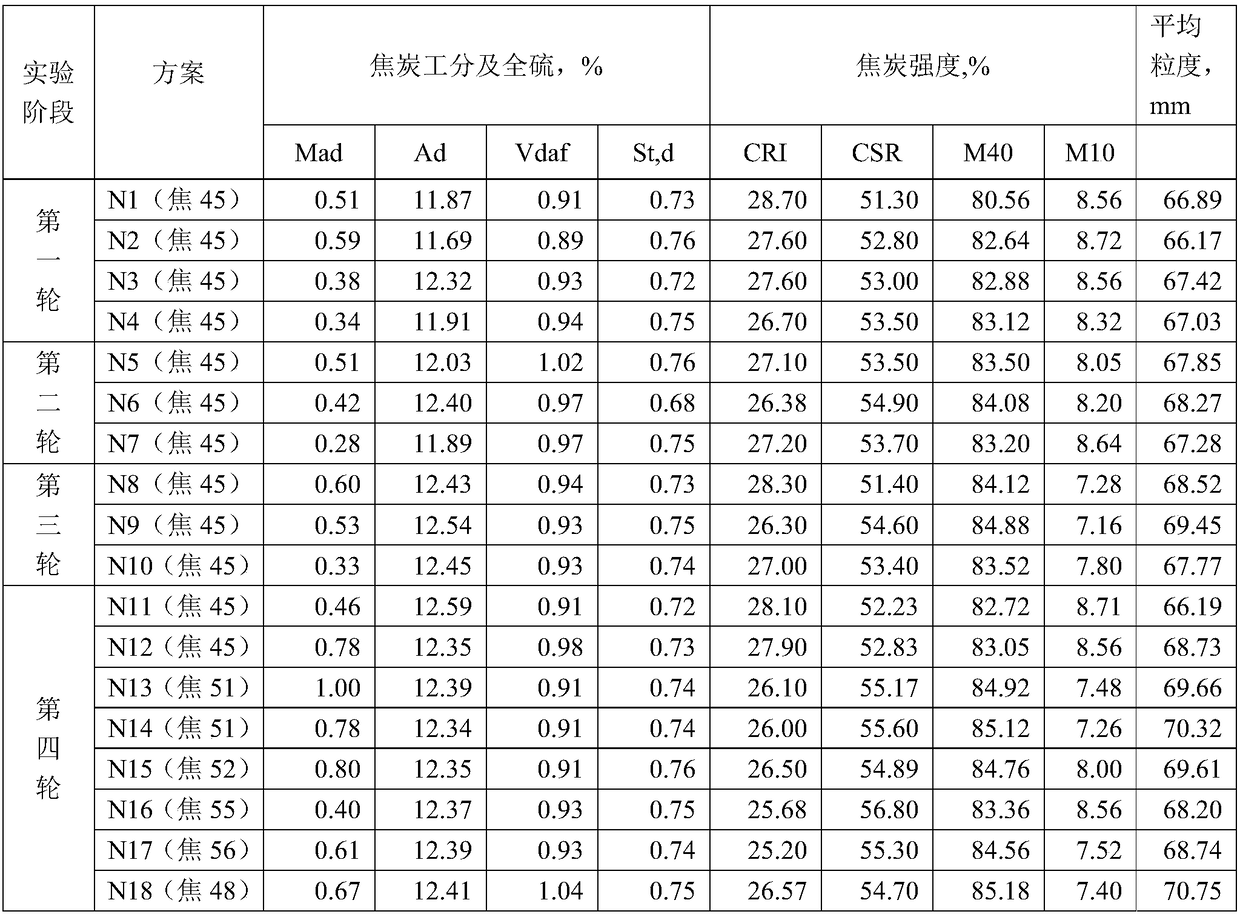

[0030] The invention uses weight as a unit to design several formulas to optimize the blending amount of five major types of coal such as 1 / 3 coke, gas, fertilizer, coke, and lean coal, and perform several sets of small coke oven experiments; it is concluded that the top-loading coke oven is matched with coal , Including the following weight percentages of raw coal: 1 / 3 coking coal 10-23%, lean coal 10-15%, coking coal 45-56%, gas fat coal 0-10% and fat coal 12-22%. Comparing the coke quality data after the small coke oven test, the best experimental ratio is preferred; preferably, the top-loaded coke oven blended coal includes the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com