Rice vinegar and its preparation method

A technology of rice vinegar and rice, which is applied in the field of flavored fermented rice vinegar and its preparation, can solve the problems of complex strains, long fermentation cycle, high failure rate, etc., and achieve the effects of preventing the mixing of bacteria, improving the taste and increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

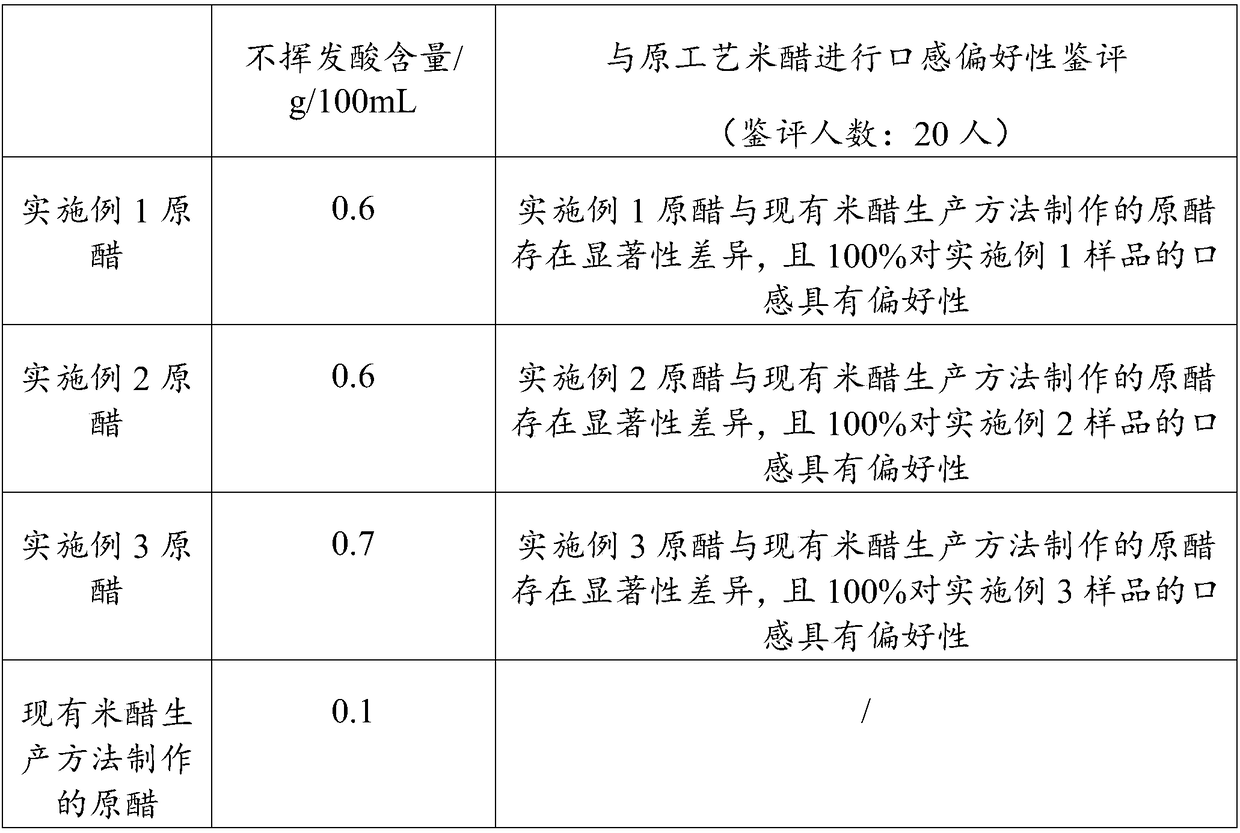

Embodiment 1

[0026] A kind of embodiment of the preparation method of rice vinegar of the present invention, the preparation method of rice vinegar described in the present embodiment is:

[0027] (1) Take 500kg of japonica rice, pour it directly into the rice soaking tank, add production water until the liquid level of the water is 10cm higher than the rice, to ensure that the rice is completely soaked in water;

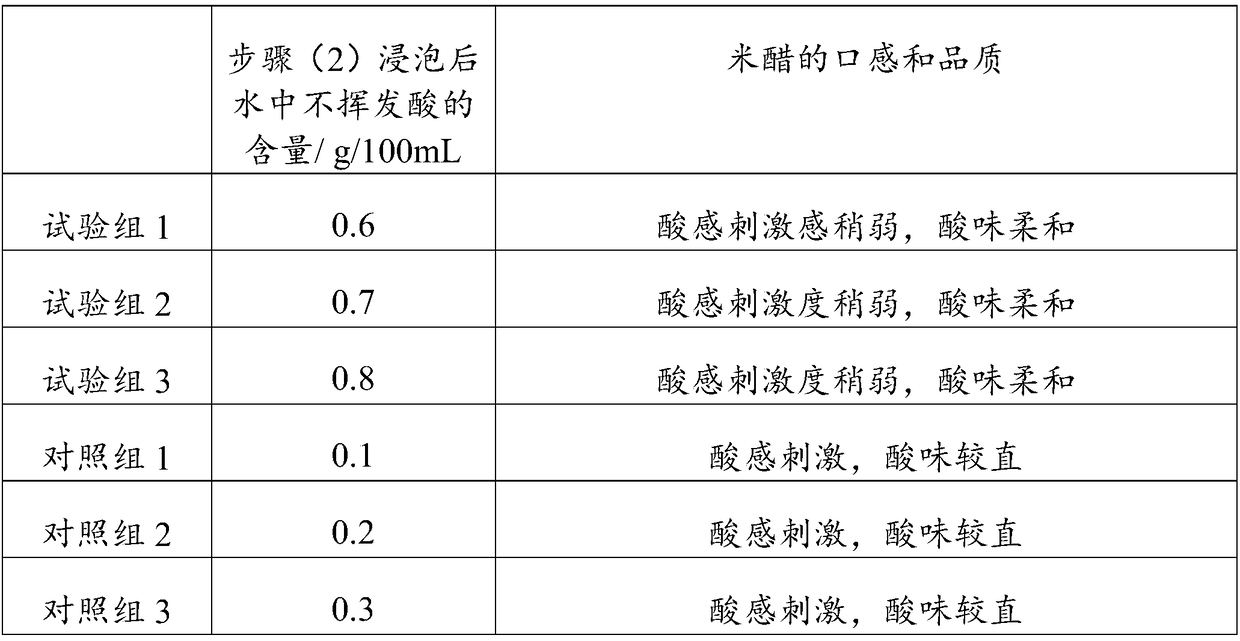

[0028] (2) After the water to be soaked in rice is left still to clarified from turbidity, add rice liquefied mash containing lactic acid bacteria to the rice, the concentration of lactic acid bacteria in the rice liquefied mash is 10 6 CFU / mL, the weight ratio of rice liquefaction mash to step (1) japonica rice is 0.1%; Seal the rice soaking tank and open the agitator for 5-10min to make the material mix evenly, and detect the non-volatile acid content in the supernatant after standing for 55h The content is 0.62g / 100mL, stop standing;

[0029] (3) pump the Physalis water and ...

Embodiment 2

[0033] A kind of embodiment of the preparation method of rice vinegar of the present invention, the preparation method of rice vinegar described in the present embodiment is:

[0034] (1) Take 400kg of japonica rice, pour it directly into the rice soaking tank, add production water until the liquid level of the water is 11cm higher than the rice, to ensure that the rice is completely soaked in water;

[0035] (2) After the water to be soaked in rice is left still to clarified from turbidity, add rice liquefied mash containing lactic acid bacteria to the rice, the concentration of lactic acid bacteria in the rice liquefied mash is 10 5 CFU / mL, the weight ratio of rice liquefaction mash to step (1) japonica rice is 0.15%; Seal the rice soaking tank and open the agitator for 5-10min to make the material mix evenly, and detect the non-volatile acid content in the supernatant after standing for 58h The content is 0.64g / 100mL, stop standing;

[0036] (3) Pump the physalis water and...

Embodiment 3

[0040] A kind of embodiment of the preparation method of rice vinegar of the present invention, the preparation method of rice vinegar described in the present embodiment is:

[0041] (1) Get 450kg of glutinous rice, directly pour it into the rice soaking tank, add production water until the liquid level of the water is 12cm higher than the rice, to ensure that the rice is completely soaked in water;

[0042] (2) After the water to be soaked in rice is left still to clarified from turbidity, add rice liquefied mash containing lactic acid bacteria to the rice, the concentration of lactic acid bacteria in the rice liquefied mash is 10 7 CFU / mL, the weight ratio of rice liquefaction mash and glutinous rice in step (1) is 0.12%; Seal the rice soaking tank and open the agitator for 5-10min to make the material mix evenly, and detect the non-volatile acid content in the supernatant after standing for 56h The content is 0.61g / 100mL, stop standing;

[0043] (3) pump the Physalis water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com