Anti-bacterial health-care safflower viscose fiber spunlaced nonwoven protective material and preparation method

A viscose fiber, protective material technology, applied in non-woven fabrics, fiber processing, textiles and papermaking, etc., can solve the problems of large shrinkage and deformation of fabrics, high quality resistance of polyester fibers, poor dimensional stability, etc., to achieve a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

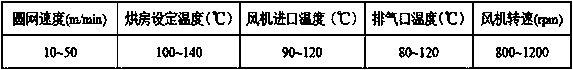

Method used

Image

Examples

Embodiment 1

[0054] A preparation method of an antibacterial health-care safflower viscose fiber spunlace nonwoven protective material, the steps are as follows:

[0055] Using the above technological process, equipment and technical measures, etc., the antibacterial health care safflower viscose fiber spunlace nonwoven protective material has been developed, which is made of the following raw materials in weight ratio: the weight content of safflower viscose fiber accounts for 30%, the weight content of holy hemp fiber accounts for 10%, the weight content of polylactic acid fiber accounts for 10%, the weight content of Amicor fiber accounts for 10%, the weight content of viscose fiber accounts for 10%, and the weight content of polyester fiber accounts for 20% , the weight content of antibacterial viscose fiber accounts for 10%.

[0056] The performance index of the antibacterial and health care safflower viscose fiber spunlace nonwoven protective material is: the actual weight is 47g / m ...

Embodiment 2

[0059] A preparation method of an antibacterial health-care safflower viscose fiber spunlace nonwoven protective material, the steps are as follows:

[0060]Using the above technological process, equipment and technical measures, etc., the antibacterial and health-care safflower viscose fiber spunlace nonwoven protective material has been developed, wherein it is made of the following raw materials with the following weight ratio: the weight of safflower viscose fiber 20% by weight, 10% by weight of holy hemp fiber, 15% by weight of polylactic acid fiber, 5% by weight of Amicor fiber, 10% by weight of viscose fiber, and 10% by weight of polyester fiber 10%, the weight content of antibacterial viscose fiber accounts for 20%, and the weight content of antibacterial polyester fiber accounts for 10%.

[0061] The performance index of the antibacterial and health care safflower viscose fiber spunlace nonwoven protective material is: the actual weight is 45.1g / m 2 , average thickne...

Embodiment 3

[0064] A preparation method of an antibacterial health-care safflower viscose fiber spunlace nonwoven protective material, the steps are as follows:

[0065] Using the above technological process, equipment and technical measures, etc., the antibacterial and health-care safflower viscose fiber spunlace nonwoven protective material has been developed, wherein it is made of the following raw materials with the following weight ratio: the weight of safflower viscose fiber 15% by weight, 15% by weight of holy hemp fiber, 5% by weight of polylactic acid fiber, 15% by weight of Amicor fiber, 15% by weight of viscose fiber, 15% by weight of polyester fiber 10%, the weight content of antibacterial polyester fiber accounts for 10%, and the weight content of antibacterial viscose fiber accounts for 15%.

[0066] The performance index of the antibacterial and health care safflower viscose fiber spunlace nonwoven protective material is: the actual weight is 52.05g / m 2 , average thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Longitudinal strength | aaaaa | aaaaa |

| Lateral force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com