A sliding support device at the bottom of a curved-slant bridge support and a lateral displacement adjustment method

A support device and lateral displacement technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of large support cracking and shear deformation, expensive replacement of large support, loss of use function, etc., to achieve anti- High compressive strength, avoiding expensive expenses and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

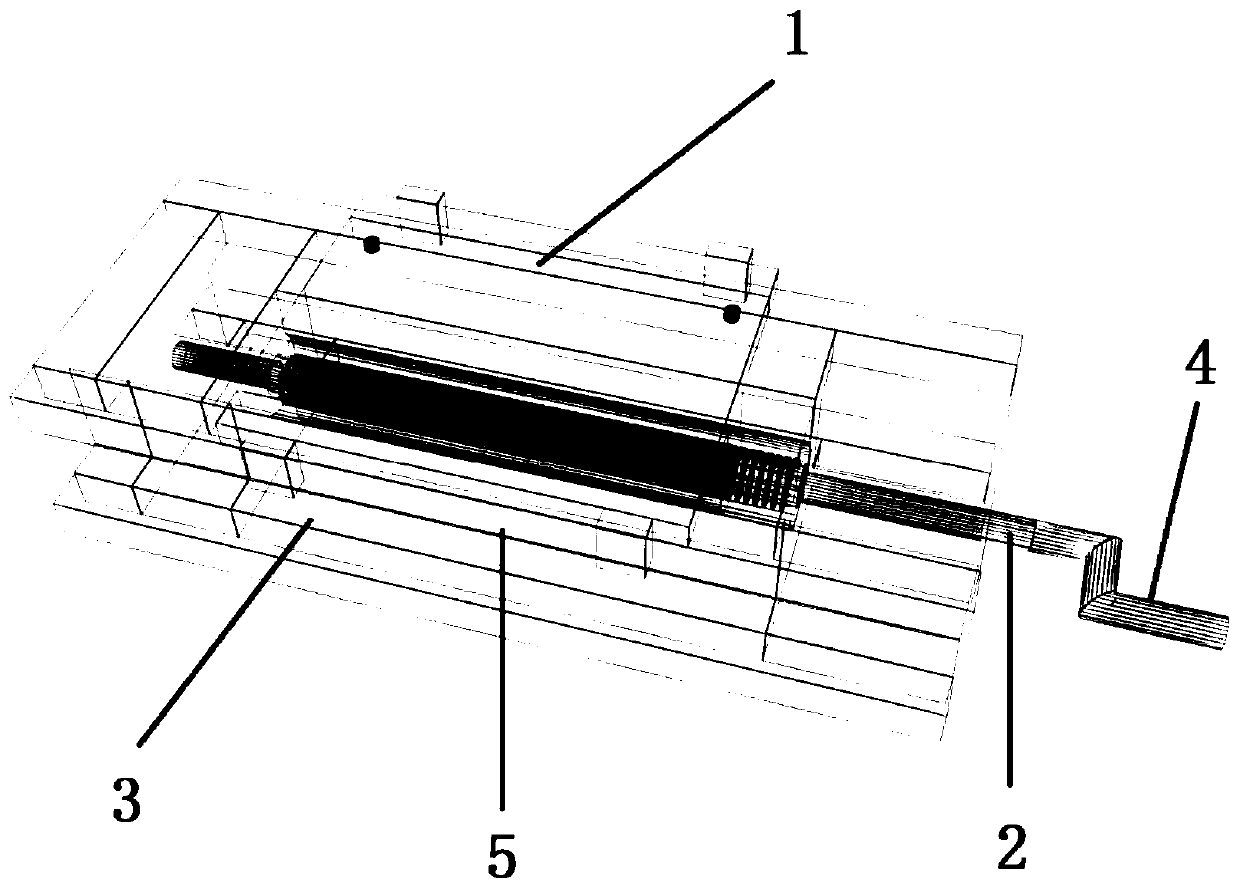

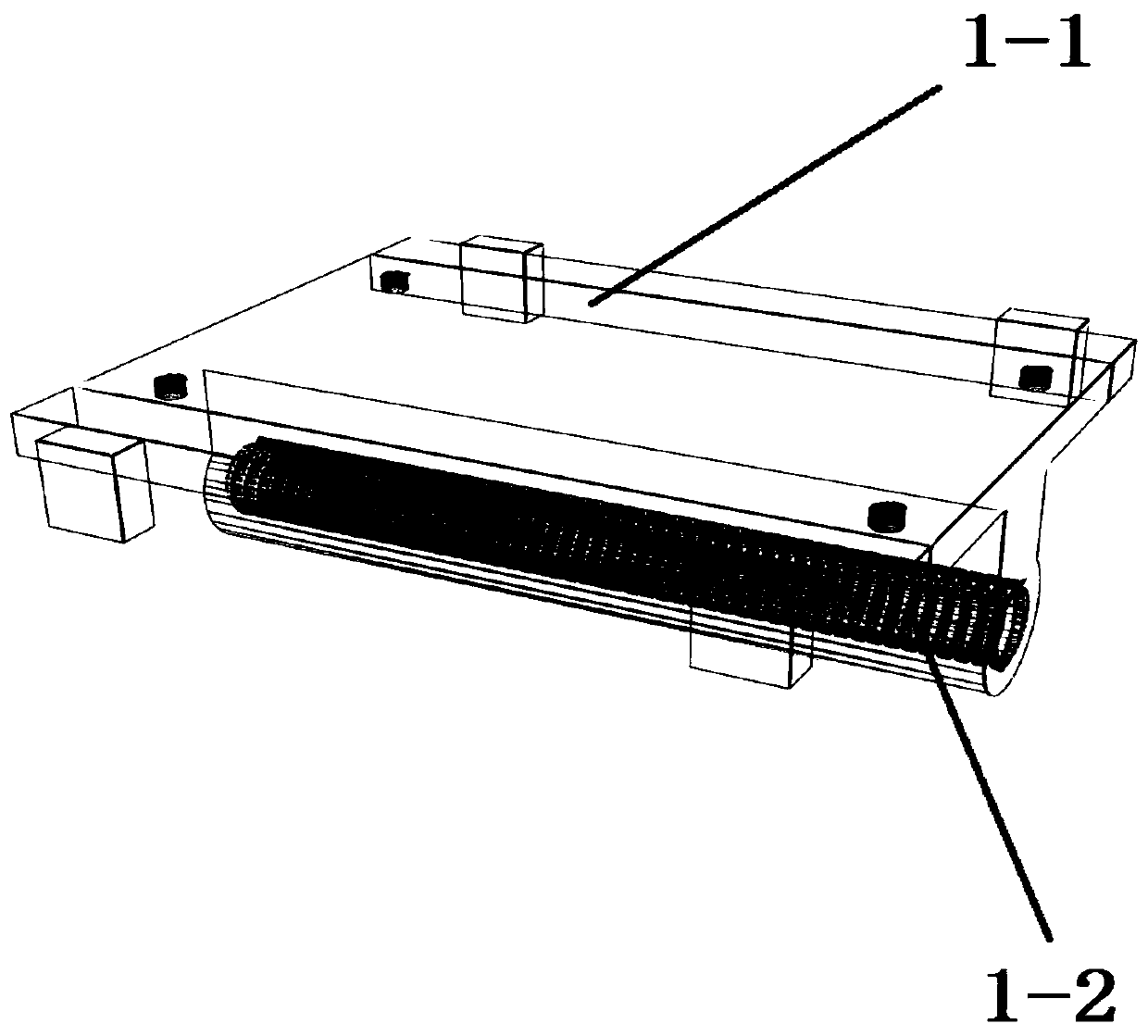

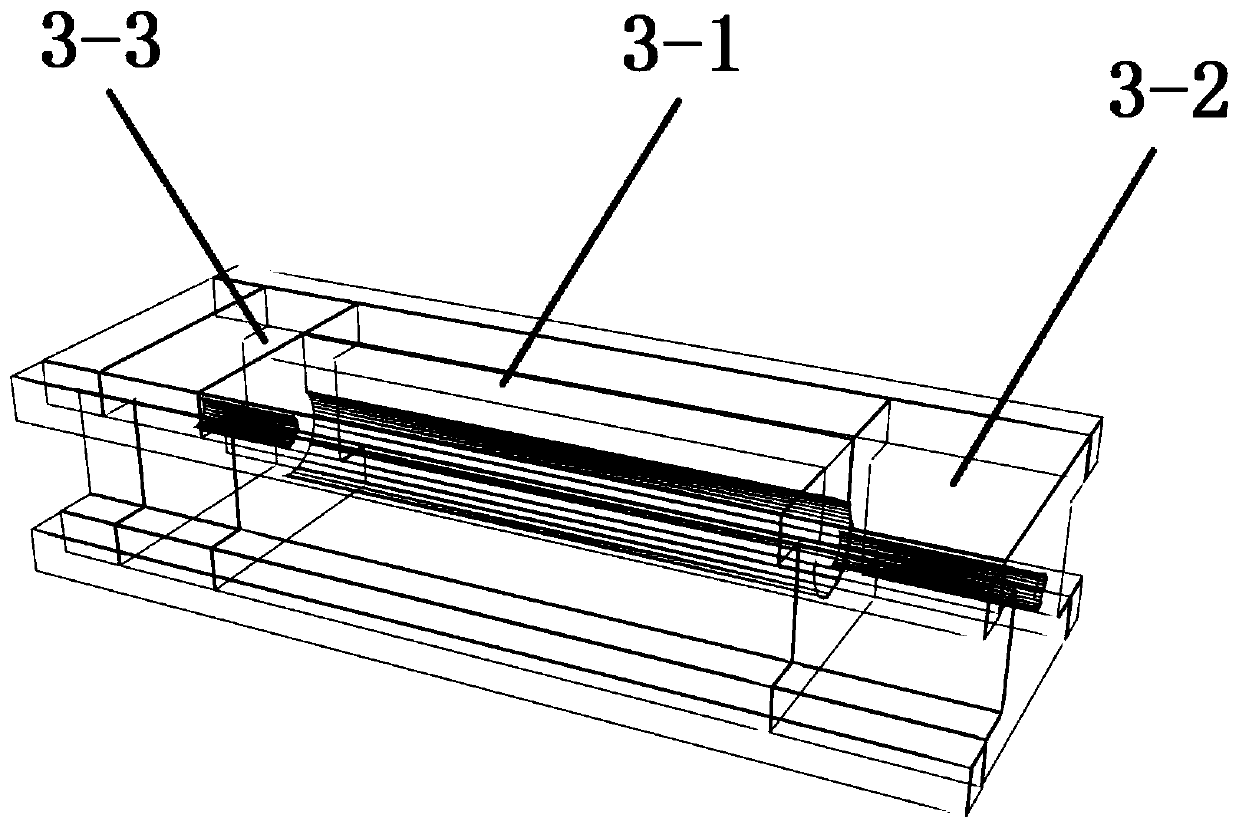

[0027] see figure 1 , The sliding support device at the bottom of the curved bridge support of the present invention structurally includes a sliding block 1, a drive screw 2, a support guide rail 3, a handle 4, a sliding gasket 5 and a temporary jack. Such as figure 2 As shown, the sliding block 1 is installed on the supporting guide rail 3, the sliding block 1 is composed of a sliding plate 1-1 and a straight thread sleeve 1-2 arranged below the sliding plate 1-1, the top of the sliding plate 1-1 is in contact with the curved The lower seat plate of the inclined bridge support is fixedly connected, the two sides of the sliding plate 1-1 are provided with limit stops 1-3 for preventing the support guide rail 3 from falling out when moving, and the transmission screw rod is installed in the straight thread sleeve 1-2 2. see Figure 4 , the driving screw 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com