Assembled type beam column node area reinforcing steel bar distribution structure

A beam-column joint and prefabricated technology, applied in truss structures, structural elements, columns, etc., can solve the problems of increasing the manufacturing cost of components, wasting resources, and imperfect prefabrication, simplifying the lifting and installation process, and saving construction time. and time cost, the effect of improving the quality of building use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The core of the present invention is to provide a prefabricated beam-column joint area reinforcement arrangement structure, which can effectively reduce the cross-sectional area of prefabricated columns, facilitate the processing and manufacturing of components, save component manufacturing costs, and increase the effective use area of buildings.

[0020] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

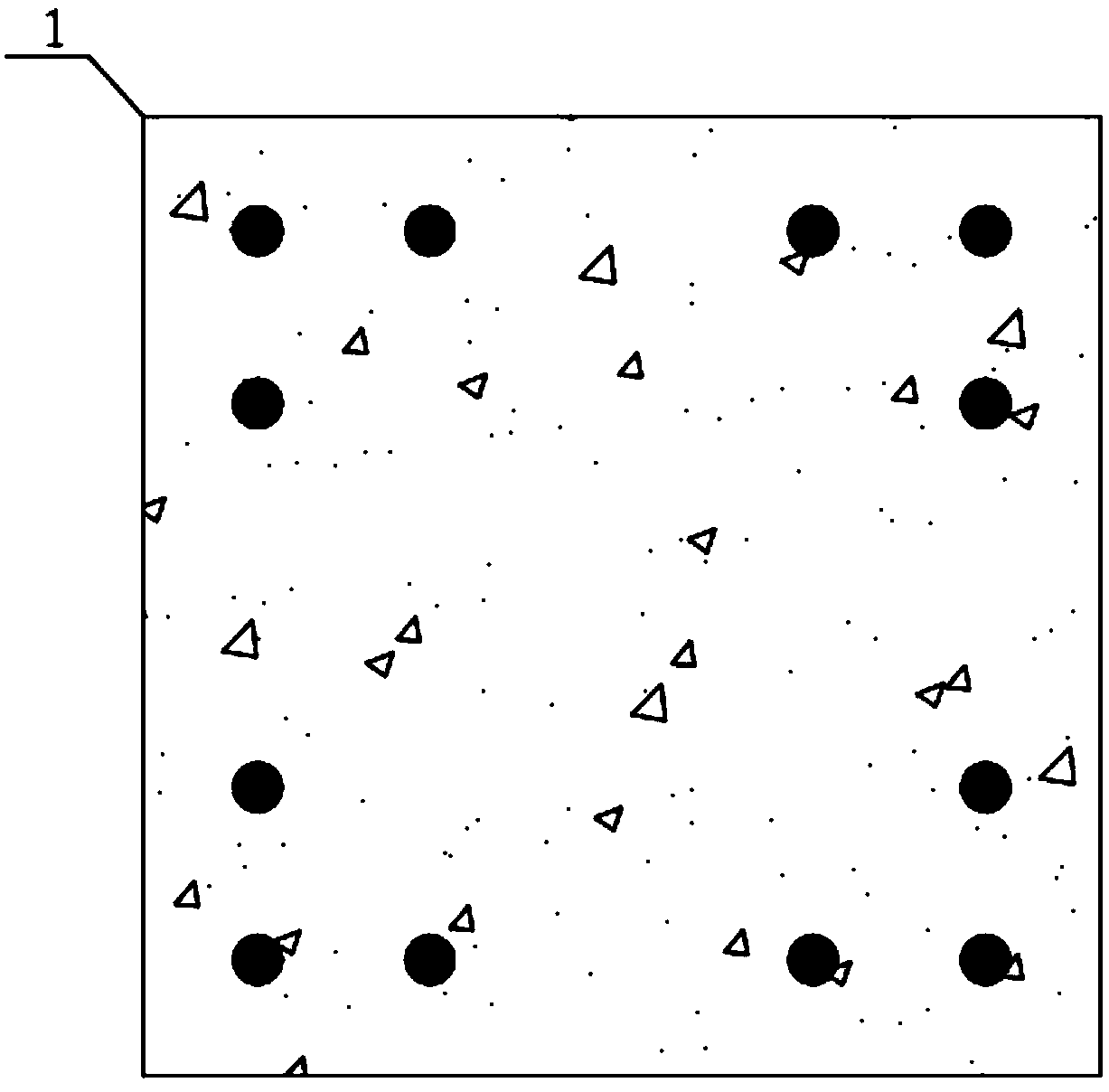

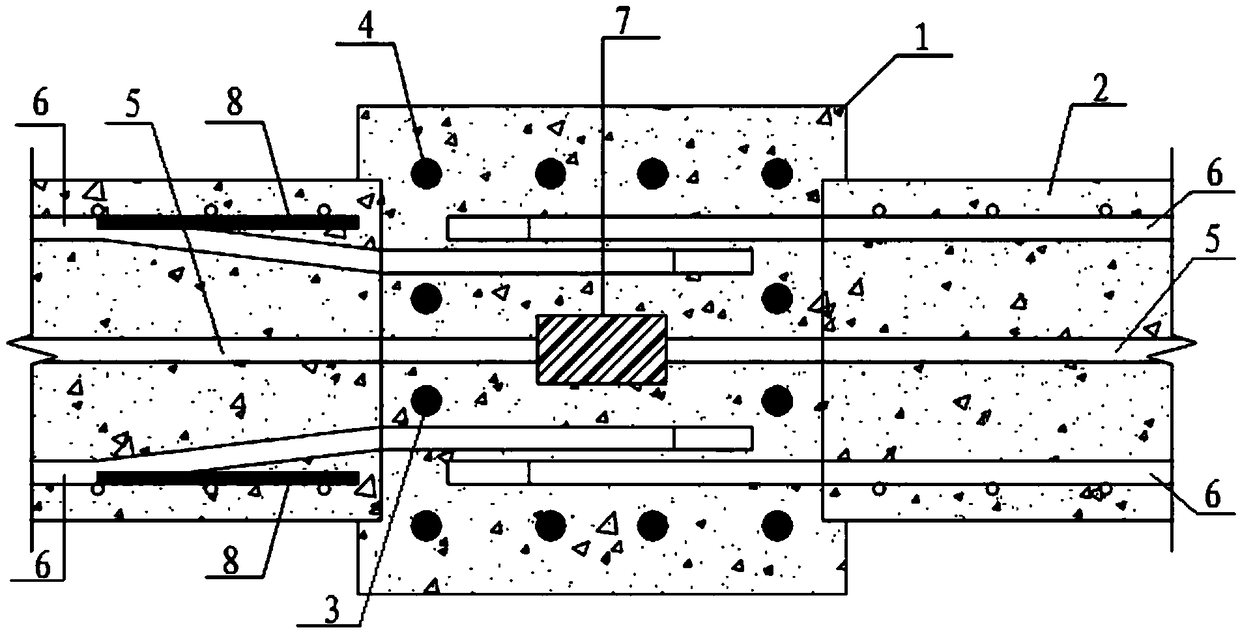

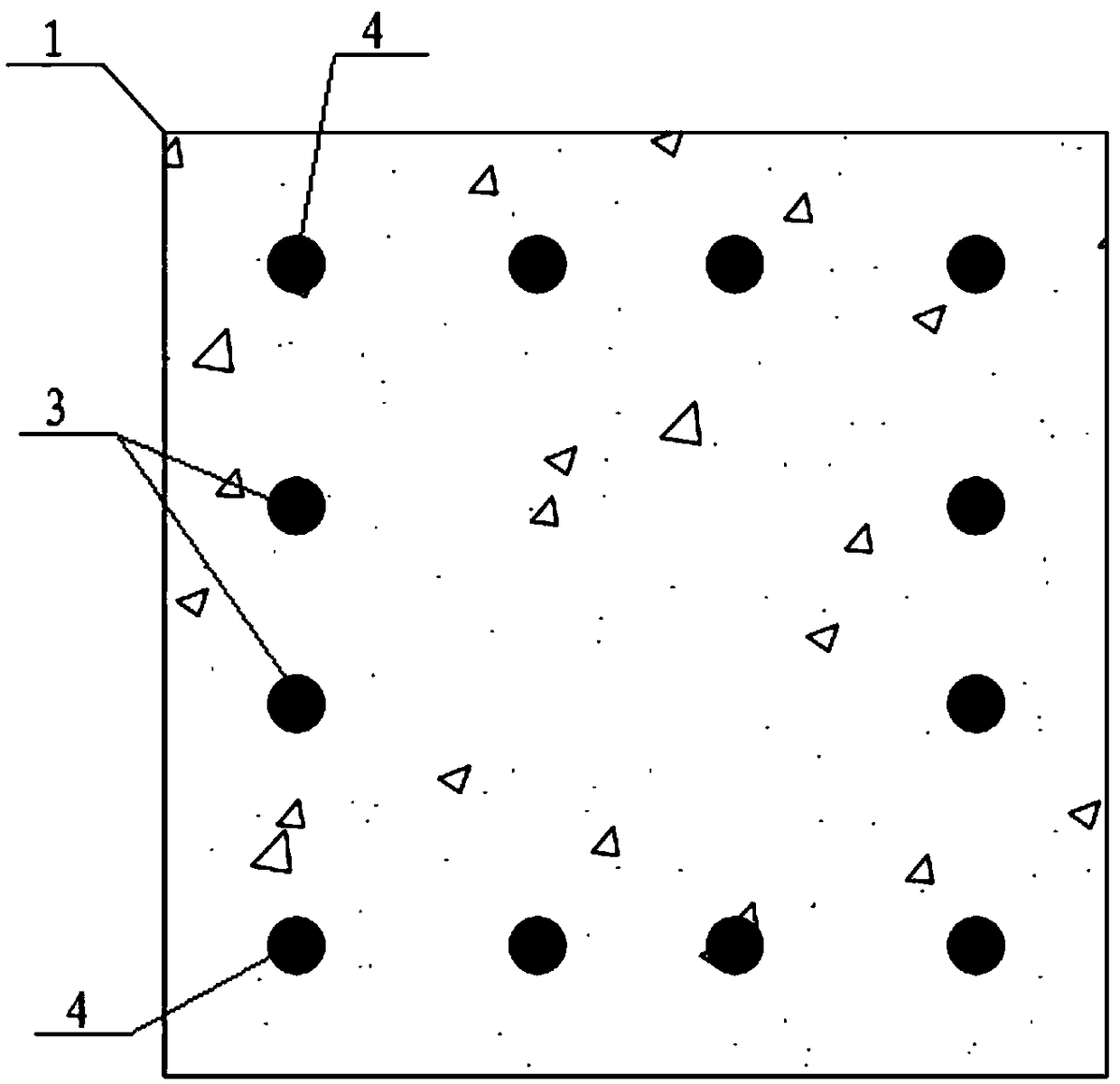

[0021] Please refer to figure 2 with image 3 , figure 2 It is a structural schematic diagram of a specific embodiment of the steel bar arrangement structure in the prefabricated beam-column node area provided by the present invention; image 3 It is a structural schematic diagram of a specific embodiment of the prefabricated column provided by the present invention.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com