Precompression combination type nonlinear spring vertical vibration isolation device

A combined, non-linear technology, applied in low internal friction springs, protective buildings/shelters, roads, etc., can solve the problem that the spring stiffness cannot be well fixed, the residents' health and work efficiency are unfavorable, and the train operation Safety hazards and other issues, to achieve the effect of effectively isolating vibration, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

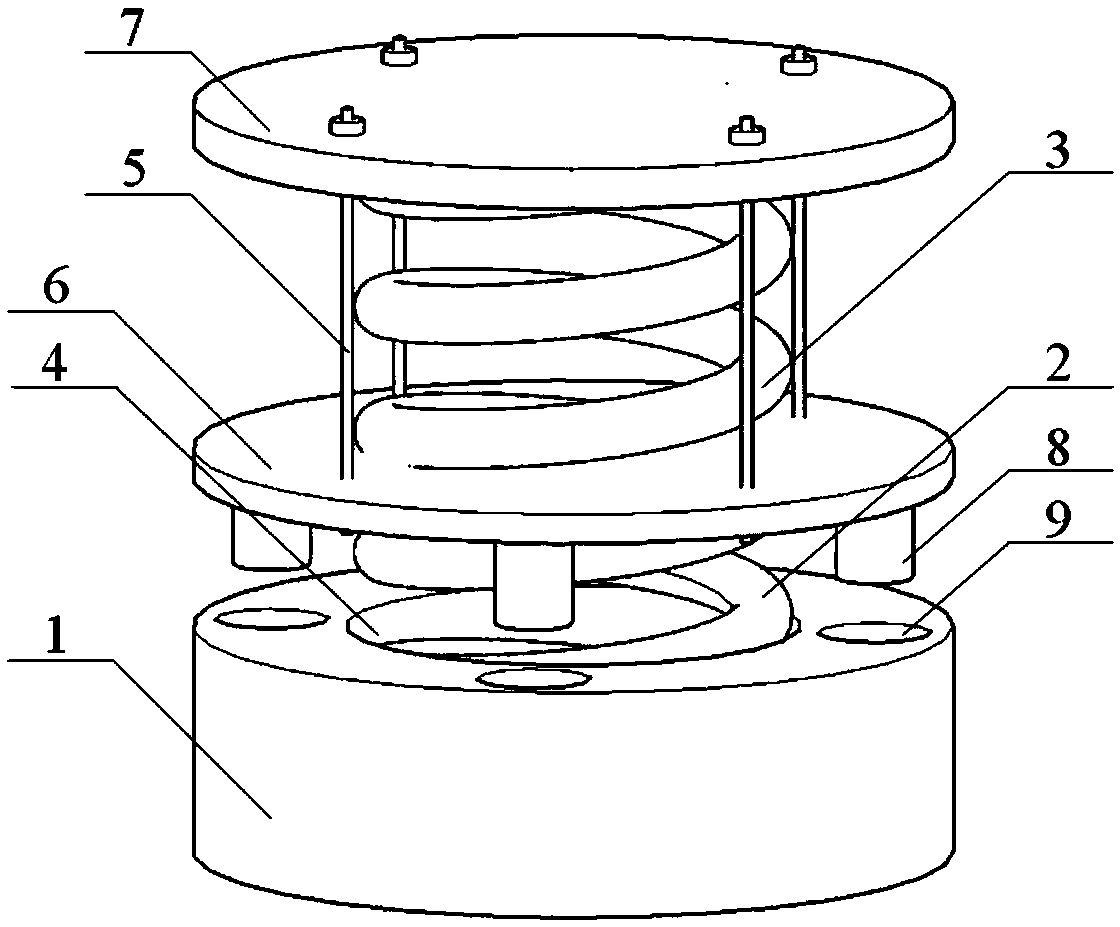

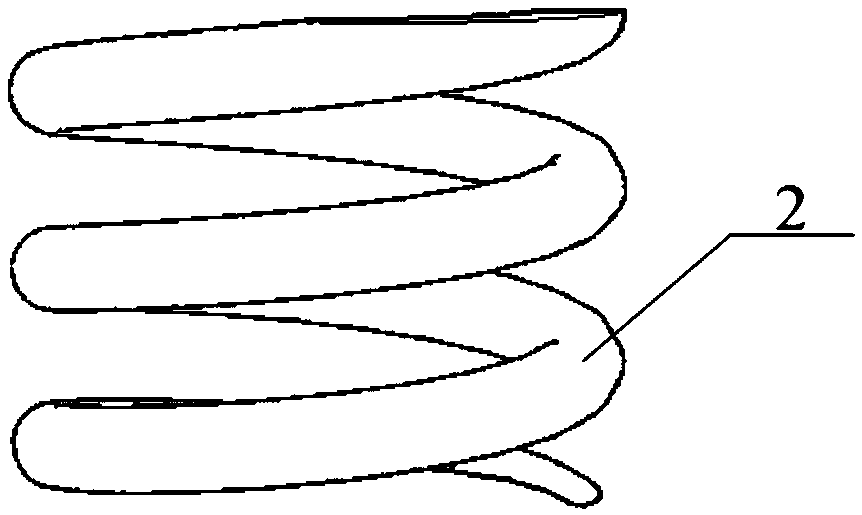

[0043] Such as figure 1 As shown, a preloaded combined nonlinear spring vertical vibration isolation device includes a base 1, a No. 1 coil spring 2, a No. 2 coil spring 3, a viscous damping material 4, a prestressed tendon 5, and a middle plate 6 , Upper cover plate 7, limit rod 8 and limit hole 9.

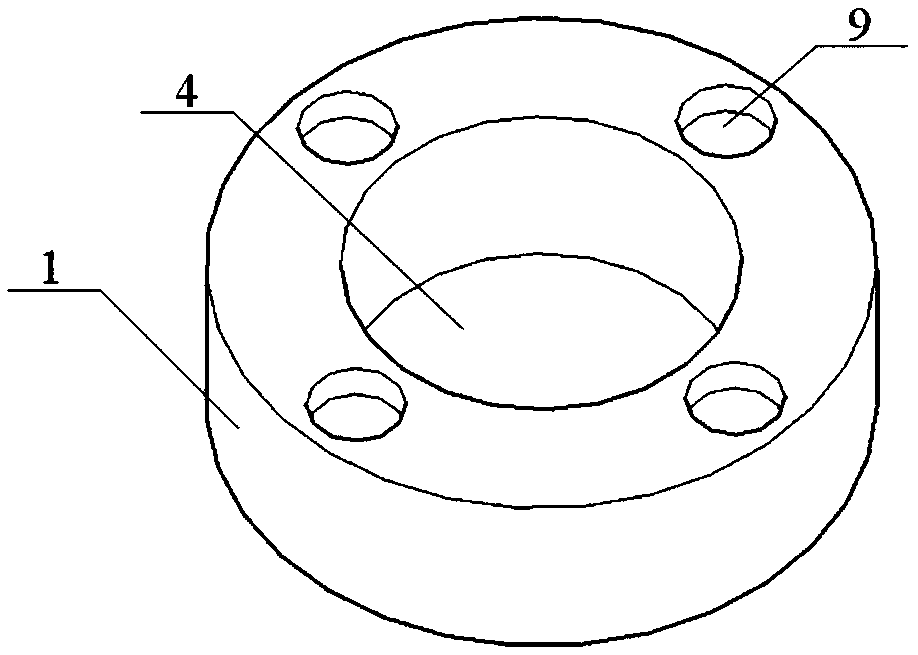

[0044] Such as figure 2 As shown, the base 1 is cylindrical, and the base 1 is provided with a central groove and four circular limiting holes 9, the central groove is filled with a viscous damping material 4, and the four limiting holes 9 are evenly arranged On the annular upper surface of the outer periphery of the central groove, a layer of rubber is tightly covered in the limiting hole 9 by bonding. The bottom center of the base 1 provides support for the No. 1 coil spring 2 at the same time.

[0045]As an example and not limitation, the viscous damping material 4 can be either damping grease or viscous damping liquid; if damping grease is used, the damping grease can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com