Experimental method and device for calibrating measuring errors of point laser displacement sensor

A technology of displacement sensor and measurement error, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of unexplored and unexplained inclination angle experiments, and achieve the simplification of experimental workload, strong pertinence, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

[0021] In order to overcome the problems of the point laser displacement sensor in the above-mentioned measurement process, the object of the present invention is to provide a method and device for correcting the measurement error of the point laser displacement sensor. The method and device can effectively improve the measurement accuracy and efficiency, and can be widely used to industrial applications.

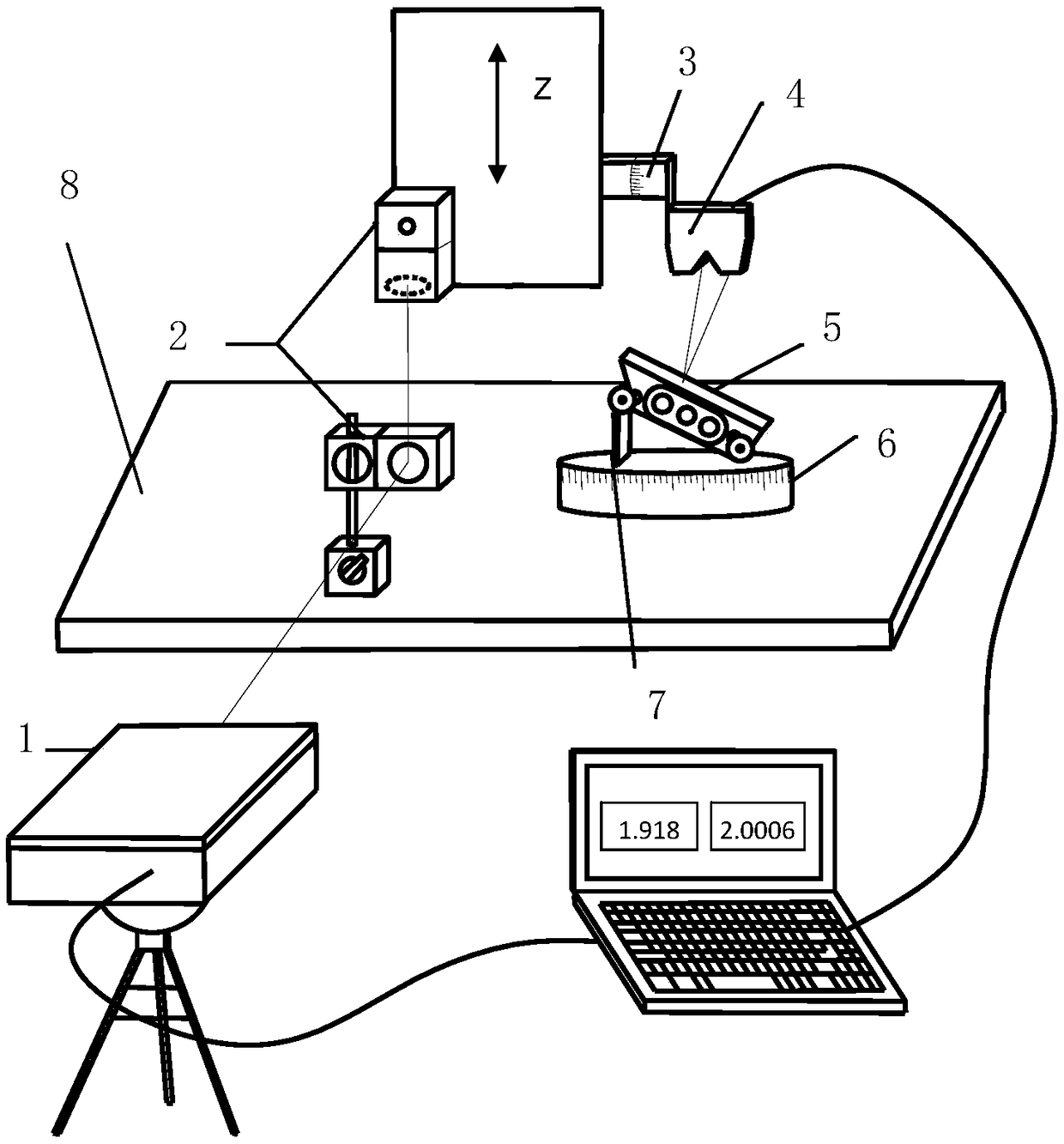

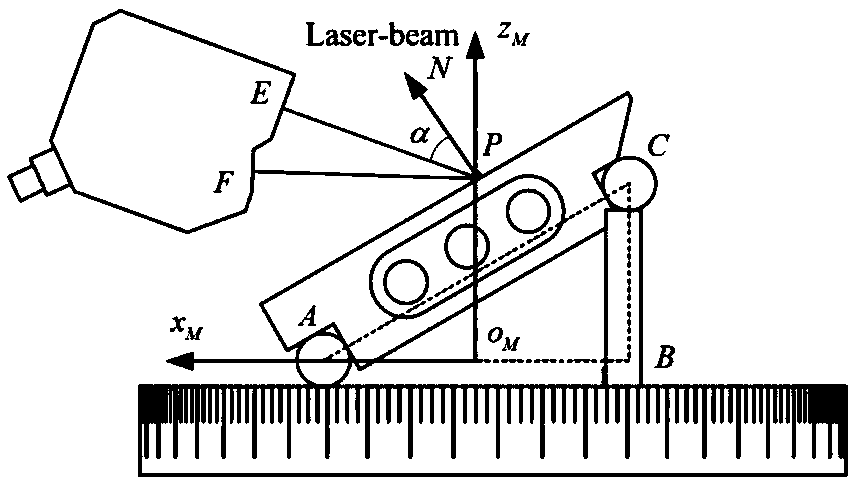

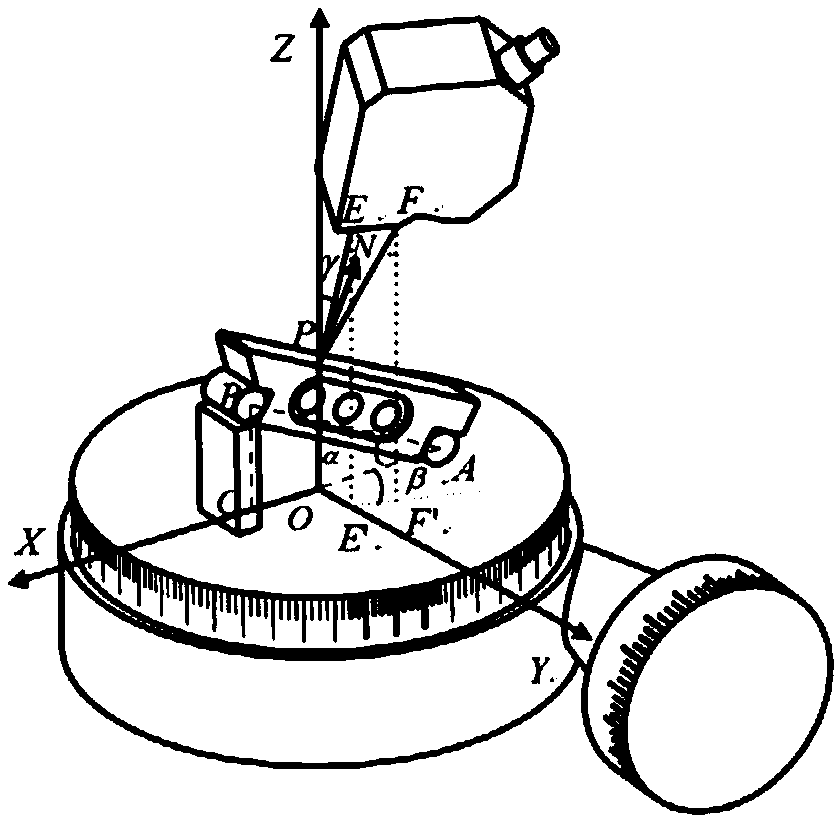

[0022] see figure 1 Schematic diagram of the structural composition of the experimental device for point laser displacement sensor measurement error correction. The experimental device for point laser displacement sensor measurement error correction is equipped with a laser interferometer 1, an optical path assembly 2, a six-degree-of-freedom fixing frame 3, and a point laser displacement sensor 4 , sine gauge 5, index plate 6, standard gauge bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com