Phased array laser ultrasonic detection system

A detection system, laser ultrasonic technology, applied in the direction of material analysis using sonic/ultrasonic/infrasonic waves, measuring devices, material analysis by optical means, etc., to achieve the effect of manufacturing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

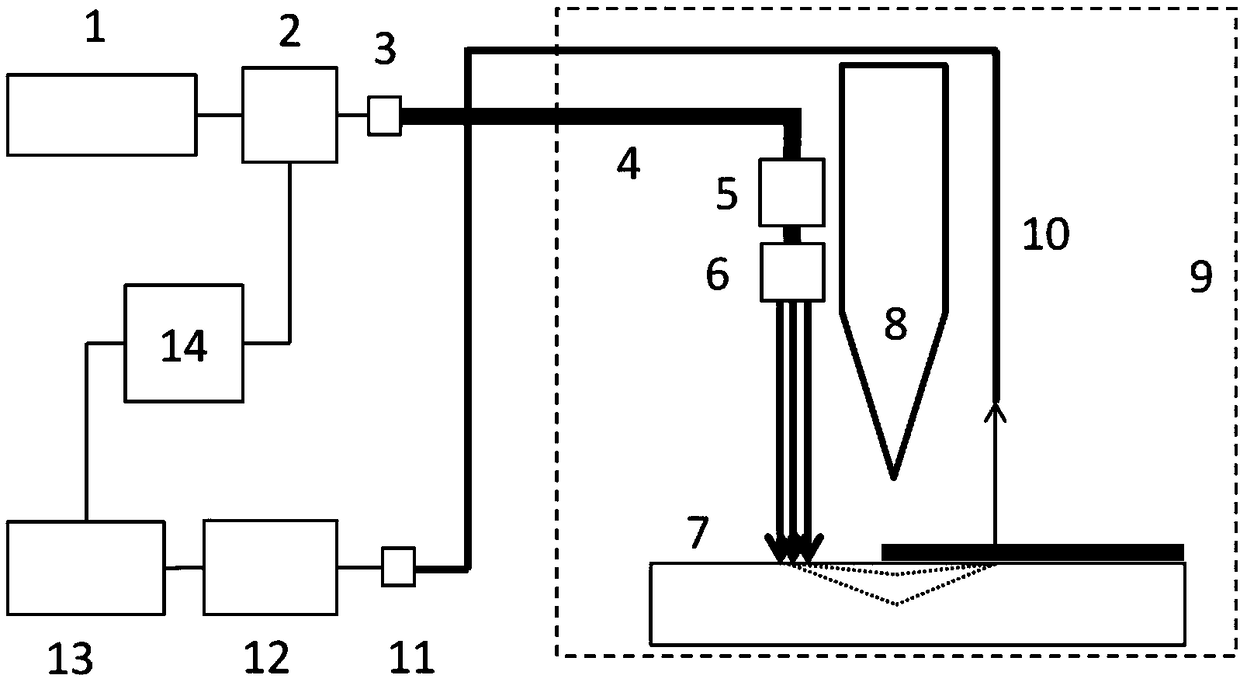

[0024] like figure 1 As shown, the phased array laser ultrasonic detection system includes an ultrasonic phased array transmitting system, a receiving system and a control system.

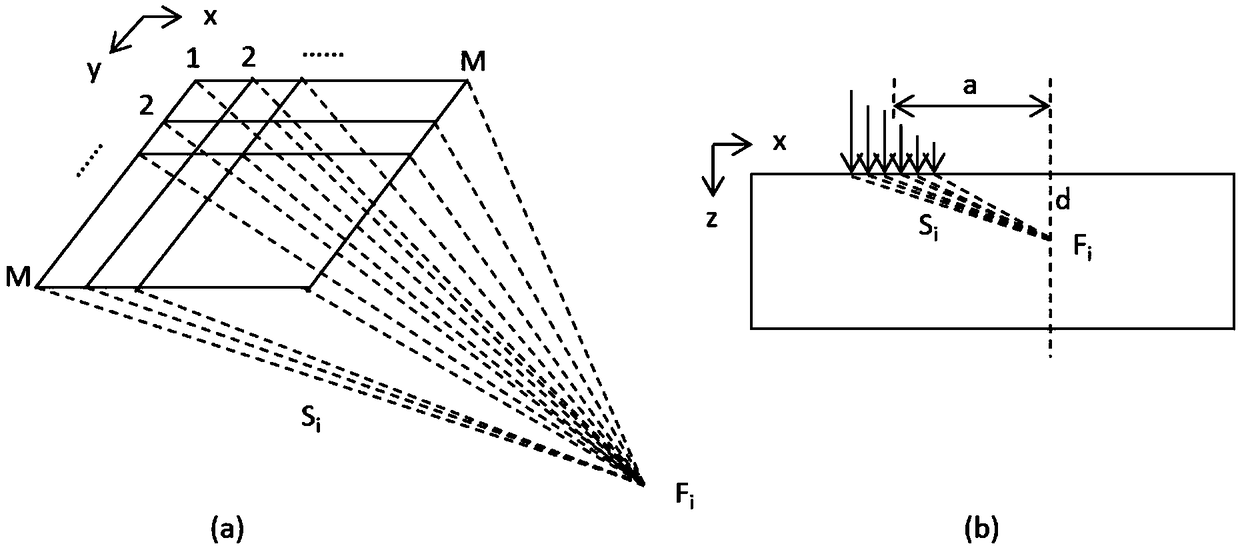

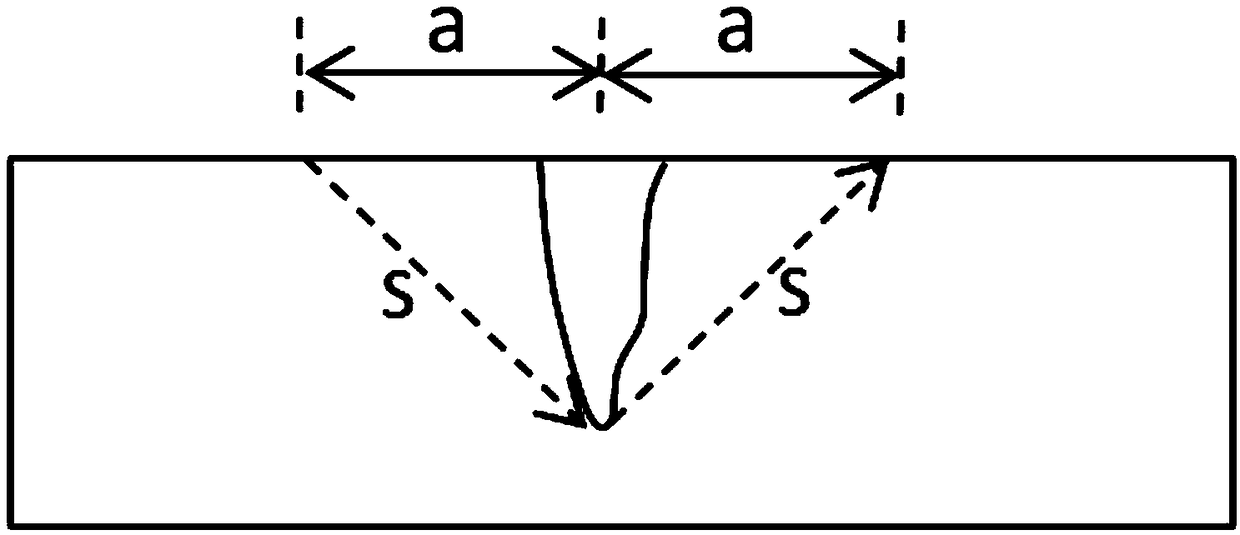

[0025] The ultrasonic phased array transmitting system includes a laser component for generating multiple delayed beams of light paths, and an area array fiber component for outputting multiple beams of the light paths to form a desired array.

[0026] The laser component can have the following three composition schemes:

[0027] 1. It includes a continuous laser, a picosecond laser switch for converting the optical path emitted by the continuous laser into multiple optical paths and delaying the emission, and an optical fiber for connecting the continuous laser and the linear array fiber assembly or the area array optical fiber assembly Coupling joint; 2. It includes a pulse laser, a piezoelectric expander for dynamically adjusting the length of the optical fiber array, at least the middle sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com