A manufacture supervision site real-time management platform

A management platform and on-site management technology, applied in the direction of manufacturing computing systems, data processing applications, instruments, etc., can solve problems affecting the safety and stable operation of UHV substation equipment, so as to promote timely reporting and rapid circulation, strengthen management, and speed up The effect of closed loop speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

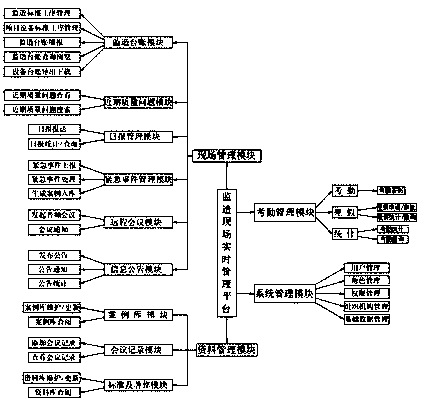

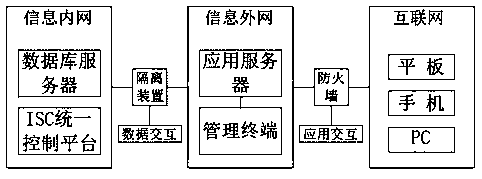

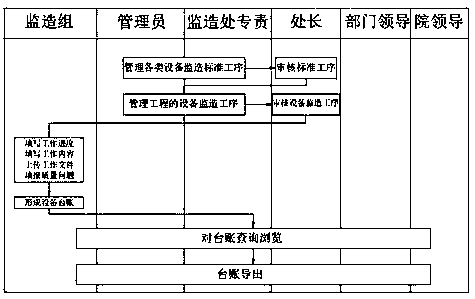

[0021] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a real-time management platform for manufacturing supervision, including attendance management module, system management module, on-site management module and data management module, attendance management module includes attendance, time off and statistics, system management The modules include user management, role management, authority management, organization management and basic data management. The on-site management module includes supervision ledger, recent quality problems, daily management, emergency management, remote conference and information announcement. The data management module includes case libraries, conference proceedings and standards and writings;

[0022] The output end of the supervision site real-time management platform is connected with the input end of the on-site management module, attendance management module, system management module and data manage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com