technology for pretreat bonded Nd-Fe-B magnetic pow

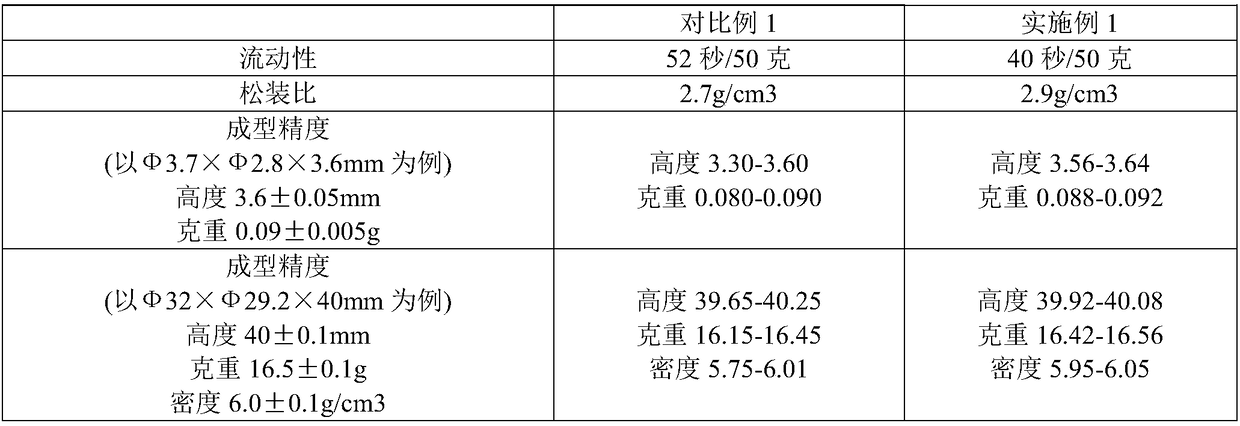

A pretreatment, neodymium iron boron technology, applied in the direction of magnetic materials, magnetic objects, metal processing equipment, etc., can solve the problems that magnetic powder cannot be filled, affect product size accuracy and performance consistency, and uneven filling, so as to improve flow stability, ensure dimensional accuracy and performance consistency, and improve the loose-to-load ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A bonded NdFeB magnetic powder pretreatment process is characterized in that it comprises the following steps:

[0035] a) Magnetic powder crushing: choose magnetic powder YH-13M 5kg from a certain domestic manufacturer, and pass through an 80-mesh sieve after magnetic powder crushing;

[0036] b) Ingredients: mix magnetic powder with epoxy resin magnetic powder glue W-6C and acetone, the amount of epoxy resin magnetic powder glue W-6C added is 1.5wt%, and the amount of acetone added is 8wt%;

[0037] c) stirring mixing: the stirring speed of stirring mixing is 5Hz, and the stirring time is 30 minutes;

[0038] d) Drying: the temperature during drying is 45°C, and the drying time is 100 minutes;

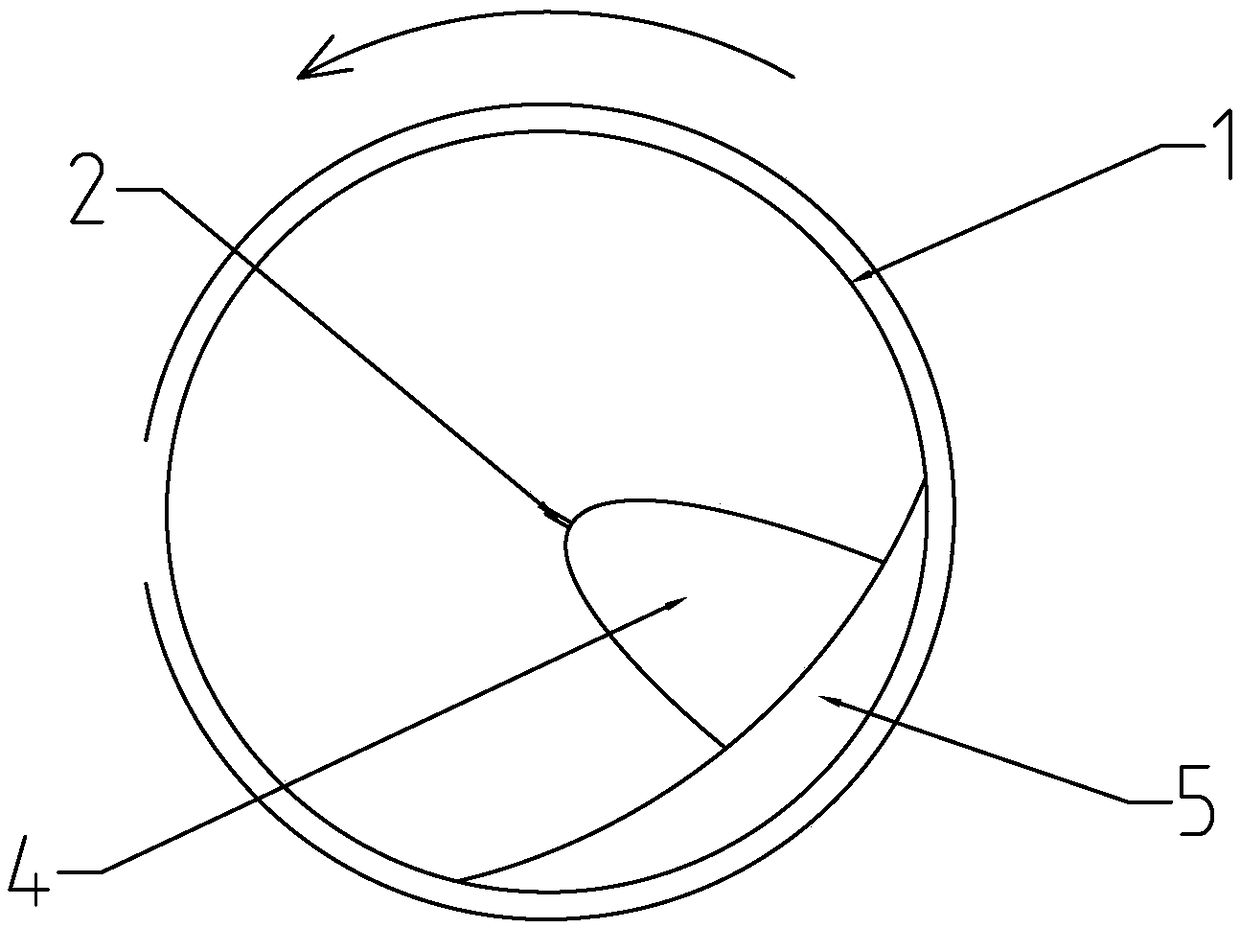

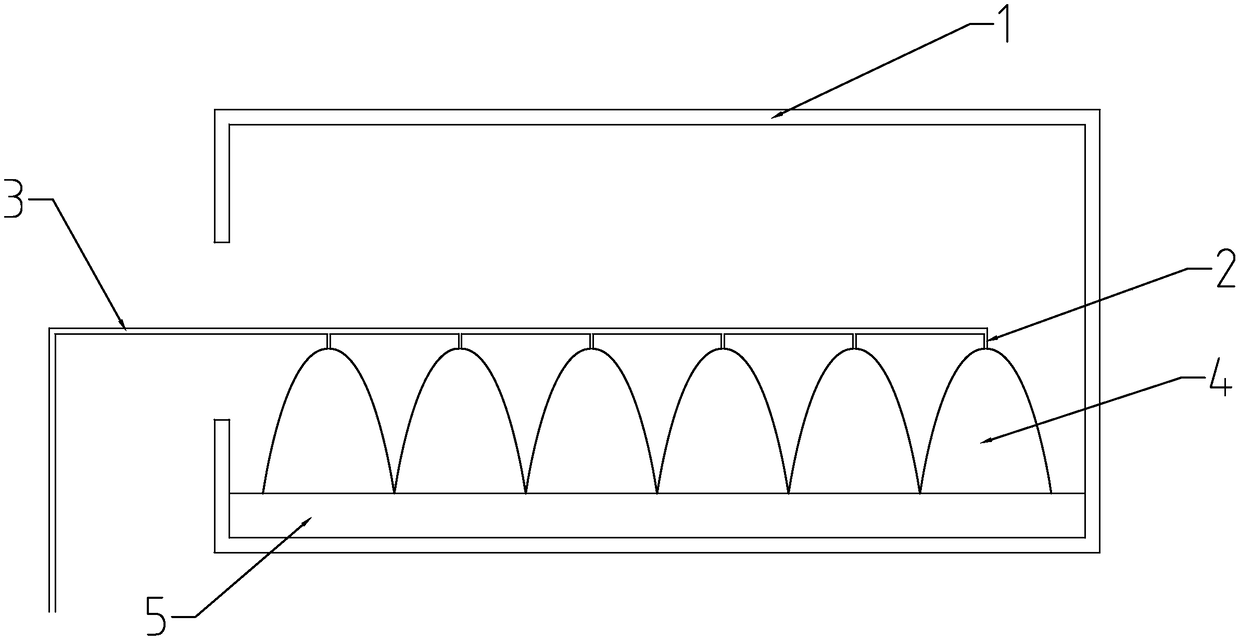

[0039] e) Rolling spray granulation: Add the above-mentioned treated magnetic powder into the drum and roll it, and spray on the top of the magnetic powder at the same time; when the drum rolls, the linear velocity of the inner cylinder wall is 0.5m / s, and the spray radius on...

Embodiment 2

[0043] A bonded NdFeB magnetic powder pretreatment process is characterized in that it comprises the following steps:

[0044] a) Magnetic powder crushing: choose magnetic powder XQP14-12 5kg from a domestic manufacturer, and pass through a 100-mesh sieve after magnetic powder crushing;

[0045] b) Ingredients: mix magnetic powder with epoxy resin magnetic powder glue W-6C and acetone, the amount of epoxy resin magnetic powder glue W-6C added is 1.8wt%, and the amount of acetone added is 9wt%;

[0046] c) stirring mixing: the stirring speed of stirring mixing is 10Hz, and the stirring time is 40 minutes;

[0047] d) Drying: the temperature during drying is 50°C, and the drying time is 120 minutes;

[0048] e) Rolling spray granulation: Add the above-mentioned treated magnetic powder into the drum and roll, and spray on the top of the magnetic powder at the same time; when the drum rolls, the linear velocity of the inner cylinder wall is 1.2m / s, and the spray radius on the mag...

Embodiment 3

[0052] A bonded NdFeB magnetic powder pretreatment process is characterized in that it comprises the following steps:

[0053] a) Magnetic powder crushing: Select 5 kg of magnetic powder HL08-06 from a domestic manufacturer, and pass through a 120-mesh sieve after magnetic powder crushing;

[0054] b) Ingredients: mix the magnetic powder with epoxy resin magnetic powder adhesive W-6C and acetone, the addition amount of epoxy resin magnetic powder adhesive W-6C is 2.0wt%, and the addition amount of acetone is 10wt%;

[0055] c) stirring mixing: the stirring speed of stirring mixing is 15Hz, and the stirring time is 50 minutes;

[0056] d) Drying: the temperature during drying is 60°C, and the drying time is 140 minutes;

[0057] e) Rolling spray granulation: Add the above-mentioned treated magnetic powder into the drum and roll it, and spray it on the top of the magnetic powder at the same time; when the drum rolls, the linear velocity of the inner cylinder wall is 3m / s, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com