A kind of preparation method of bismuth compound nanometer photocatalyst

A nano-photocatalyst and compound technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Complex reaction process and other problems, to achieve the effect of improving photocatalytic activity, particle size uniformity and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

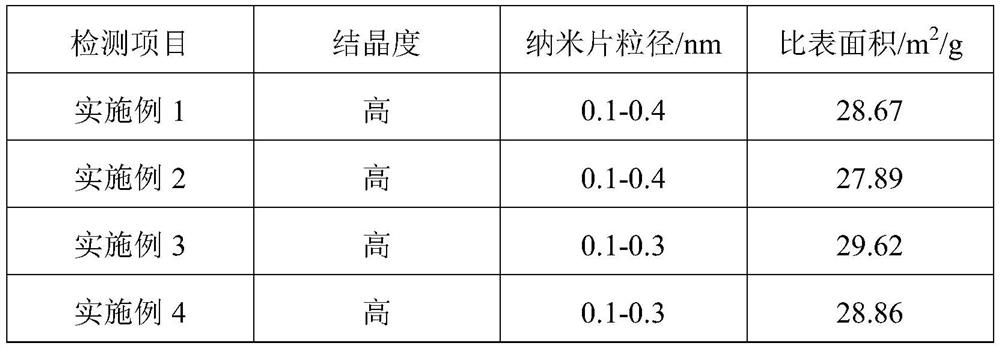

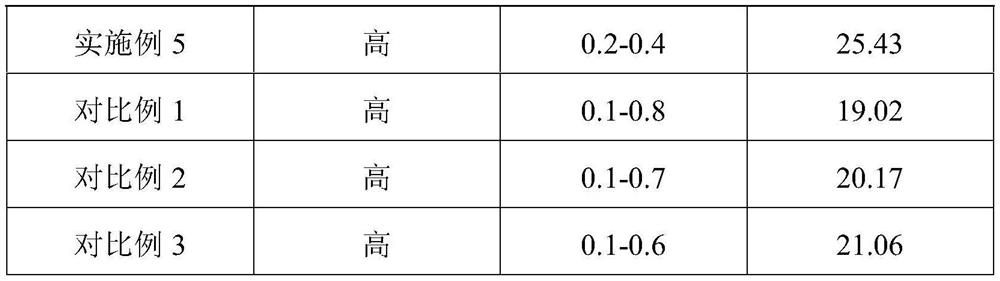

Examples

Embodiment 1

[0021] A preparation method of bismuth compound nano photocatalyst, comprising the following steps:

[0022] Step 1, dissolving sodium tungstate in water to prepare solution 1 with a tungstate concentration of 0.05mol / L;

[0023] Step 2, dissolving bismuth nitrate in dilute nitric acid with a concentration of 0.5mol / L to form a transparent solution, and then dispersing the transparent solution in water at 30°C to prepare a solution with a concentration of bismuth nitrate of 0.03mol / L two;

[0024] Step 3, stirring and mixing solution 1 and solution 2, heating to 300° C. under a pressure of 15 MPa, and keeping for 40 minutes to obtain reactant 1;

[0025] In step 4, the temperature of the reactant is lowered to 200° C., and the pressure is maintained at 10 MPa, and then passed into a closed environment of 0.05 MPa for flash evaporation to obtain a nano photocatalyst.

Embodiment 2

[0027] A preparation method of bismuth compound nano photocatalyst, comprising the following steps:

[0028] Step 1, the water-soluble sodium molybdate is dissolved in water, and it is prepared into solution one that the molybdate concentration is 0.07mol / L;

[0029] Step 2, dissolving bismuth sulfate in 0.4mol / L dilute sulfuric acid, then dispersing it in water to prepare a solution 2 with a bismuth salt concentration of 0.05mol / L;

[0030] Step 3, mixing solution 1 and solution 2, heating to 310° C. under a pressure of 16 MPa, and keeping for 35 minutes to obtain reactant 1;

[0031] In step 4, the temperature of the reactant is lowered to 206° C., and the pressure is maintained at 12 MPa, and then passed into a closed environment of 0.06 MPa for flash evaporation to obtain a nano photocatalyst.

Embodiment 3

[0033] A preparation method of bismuth compound nano photocatalyst, comprising the following steps:

[0034] Step 1, dissolving sodium tungstate in water to prepare a solution 1 with a tungstate concentration of 0.08mol / L;

[0035] Step 2, dissolving bismuth nitrate in dilute nitric acid with a concentration of 0.8mol / L to form a transparent solution, and then dispersing the transparent solution in water at 37°C to prepare a solution with a concentration of bismuth nitrate of 0.07mol / L two;

[0036] Step 3: Stir and mix solution 1 and solution 2, heat to 330° C. under a pressure of 18 MPa, and keep for 38 minutes to obtain reactant 1;

[0037] In step 4, the temperature of the reactant is lowered to 220° C., and the pressure is maintained at 13 MPa, and then passed into a closed environment of 0.07 MPa in the form of atomization for flash evaporation to obtain a nano photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com